Water-separating system of wellhead produced object and water-separating treatment method

A water phase and dissolved gas water technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problem of large area occupied by the subsequent coalescence degreaser and poor oil, gas and water three-phase separation effect , The three-phase separator occupies a large area, etc., to achieve the effect of reducing the occupied area and space volume, large processing load, and large buffer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

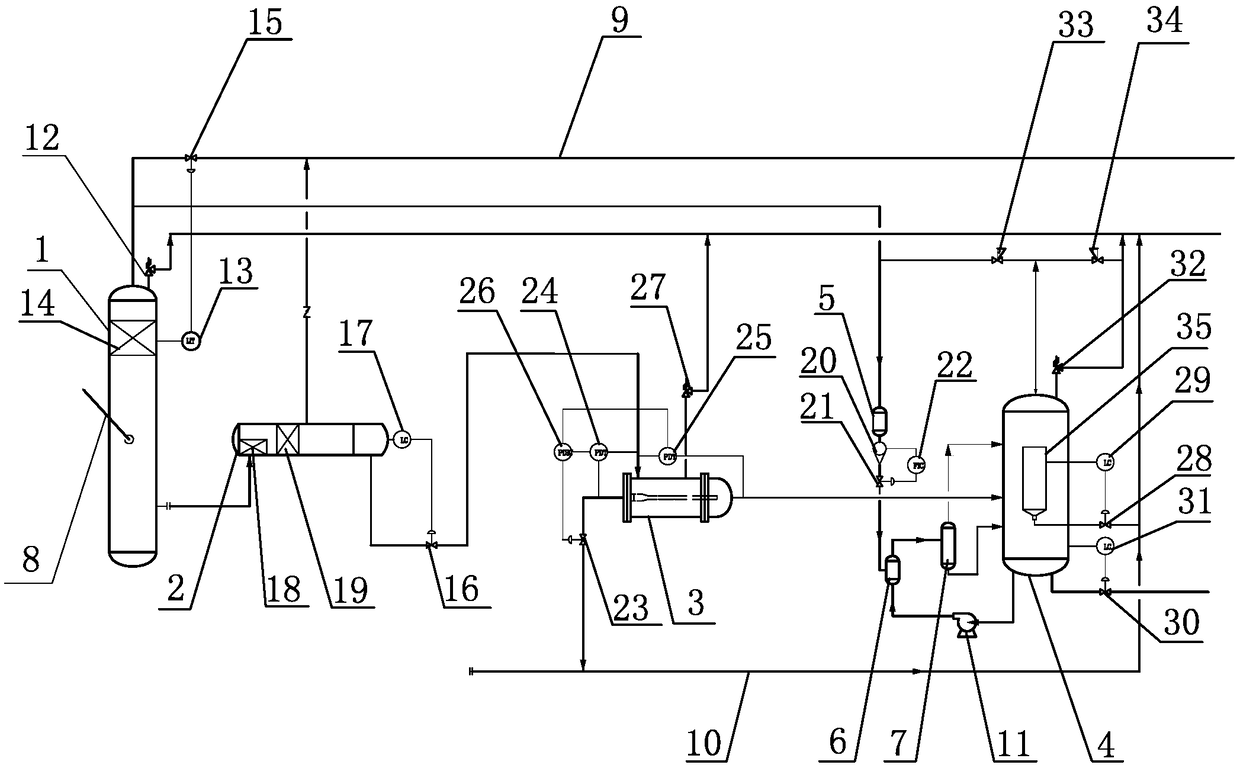

[0030] A water separation system for wellhead production, such as figure 1 As shown, it includes a columnar cyclone separator 1, a high-efficiency horizontal separator 2, a hydrocyclone 3, an air flotation tank 4, a gas filter 5, a gas injector 6, and a nano-scale microbubble generator 7. The columnar cyclone The middle part of the separator 1 is provided with a wellhead production inlet pipe 8, and the bottom liquid phase outlet of the columnar cyclone separator 1 is connected with the bottom liquid phase inlet of the high-efficiency horizontal separator 2; the top oil phase of the high-efficiency horizontal separator 2 The outlet is connected to the export pipeline 9 for crude oil export, the bottom water phase outlet of the high-efficiency horizontal separator 2 is connected to the tangential inlet of the hydrocyclone 3; the oil phase outlet of the hydrocyclone 3 is connected to the sewage sink Pipe 10, the tail water phase outlet of the hydrocyclone 3 is connected to the m...

specific Embodiment 2

[0036] A method of using the water separation system described in the above specific embodiment 1 to carry out water separation treatment of wellhead produced materials, such as figure 1 shown, including the following steps:

[0037] (1) Send the oil, gas and water three-phase wellhead production through the wellhead production inlet pipe 8 into the columnar cyclone 1, and control the temperature in the columnar cyclone 1 to 60-99°C and the pressure to 1.1 -35MPaG, at the same time, under the action of swirling flow, centrifugal force, gravity and buoyancy form an inverted conical vortex surface, the liquid phase with high density flows along the pipe wall of the vertical pipe to the bottom of the columnar cyclone separator, and the gas phase with low density Rise to the vortex surface along the center of the vortex and flow to the top of the columnar cyclone separator 1, and the separated gas phase is directly used as the gas source of the air flotation tank 4;

[0038] (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com