Preparation method, device and application of spherical magnesium oxide

A magnesium oxide, spherical technology, applied in the direction of magnesium oxide, chemical instruments and methods, and other chemical processes, to achieve the effect of high product purity, uniform particle size, and less component loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

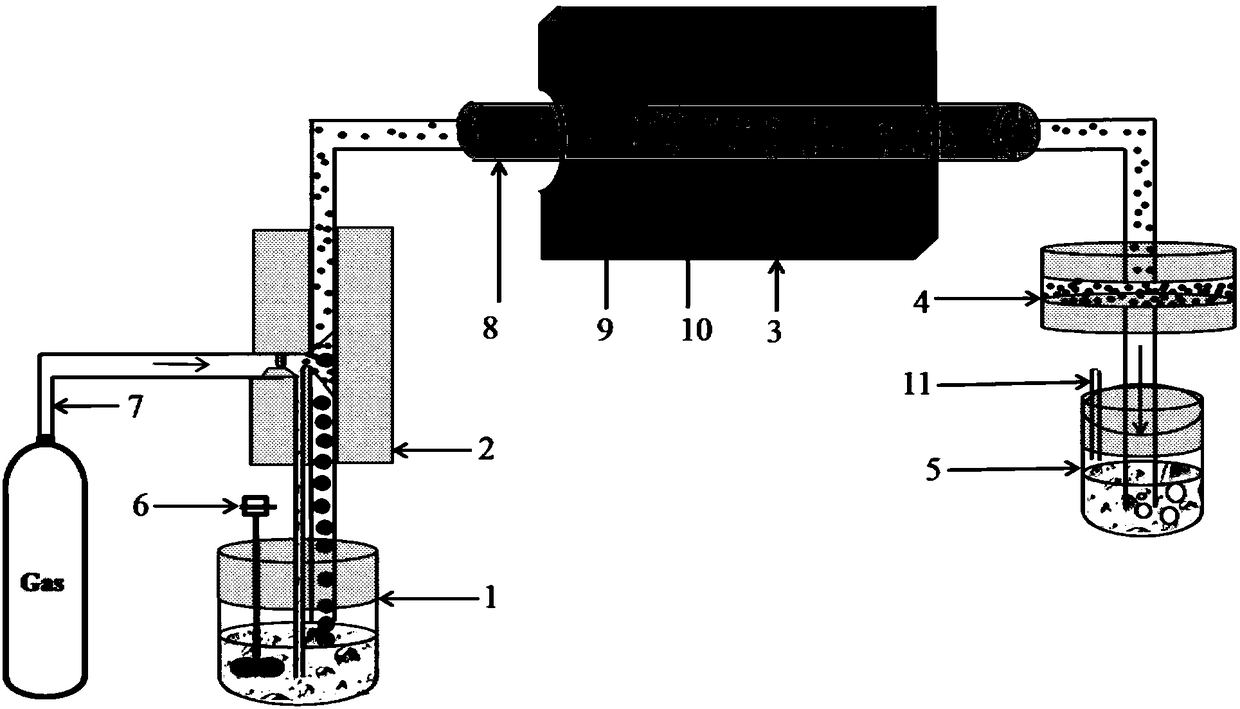

[0028] like figure 1 As shown, a device for preparing spherical magnesium oxide includes a reaction kettle 1, an aerosol generator 2, a tubular pyrolysis furnace 3, a solid-gas separator 4, and a tail gas processor 5. The reactor is made of stainless steel or glass, equipped with a mechanical stirring device 6; the aerosol generator is made of metal, and is connected to a gas cylinder or an air compressor through a pipeline 7; the tubular pyrolysis furnace includes a pipe body and a shell, and the pipe body It is a quartz tube 8. The shell is divided into upper and lower parts, which are connected by a sealed flange. The inner layer of the shell is provided with an electric furnace heating layer 9 and an insulating layer 10. The two ends are the feeding port and the discharging port. The generator 2 and the solid-gas separator 4 are connected; the solid-gas separator 4 is made of steel and is divided into upper and lower layers. The upper layer has a cavity and a sealing gaske...

Embodiment 2

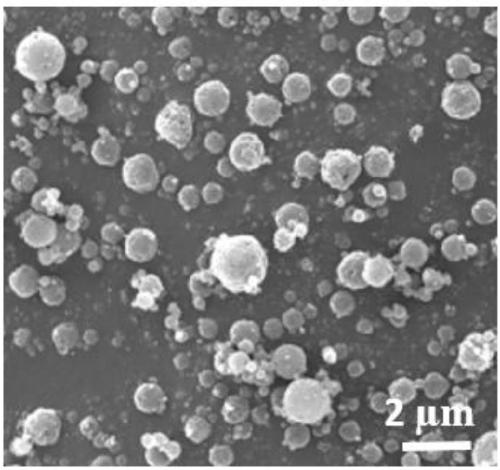

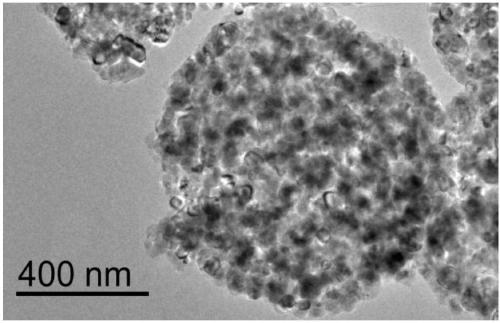

[0033] Add 2% 10mL polyethylene glycol aqueous solution to 2mol / L 100mL MgCl 2 In the aqueous solution, mix and stir for 12 hours, then add 0.5mol / L, 50mL urea aqueous solution, mix and stir, make a translucent sol at 85°C and a speed of 500r / min, cool to room temperature to obtain a precursor sol; at room temperature, a speed of 300r Under the stirring condition of / min, the precursor solution was passed through the nitrogen gas with a flow rate of 1.5L / min. figure 1 The aerosol generator and tubular pyrolysis furnace of the reaction device shown in the figure, the temperature of the tubular furnace is 600°C, the gas phase and the solid phase are separated through a solid-gas separator, and the solid powder is collected to obtain a magnesium oxide precursor; the magnesium oxide precursor body, in a muffle furnace or a tube furnace at a rate of 5°C / min to 650°C for 2h to obtain a spherical magnesium oxide product.

[0034] Use large intestine antibacterial 6.0×10 5 cfu / mL, S...

Embodiment 3

[0037] Add 20mL of 1mol / L glucose solution to 100mL of 2mol / L MgCl 2 In the aqueous solution, mix and stir evenly, and then pass the air with a flow rate of 1.5L / min through the aerosol generator and the tubular pyrolysis furnace of the reaction device. The temperature of the tubular furnace is 600 ° C, and the gas phase and solid Phase separation, collecting solid powder to obtain a magnesium oxide precursor; raising the magnesium oxide precursor in a muffle furnace or tube furnace at a rate of 5°C / min to 700°C for 2 hours to obtain a spherical magnesium oxide product.

[0038] Use large intestine antibacterial 6.0×10 5 cfu / mL, Staphylococcus aureus 5.5×10 5cfu / mL, with reference to GBT 21510-2008, QB / T2591-2003 (GB / T2591-2003A) and GBT 21866-2008 standard method test the antibacterial activity of the magnesia gained in the embodiment, the result shows that spherical magnesia is to Staphylococcus aureus and Escherichia coli antibacterial rates are greater than 98%.

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com