A pretreatment method for improving the dyeing performance of bamboo

A dyeing performance, bamboo technology, applied in wood treatment, wood treatment details, wood low-temperature treatment, etc., can solve the problems of light color, easy to fade, long size, etc., to change the cellulose structure, increase dyeing stability, and improve product quality. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

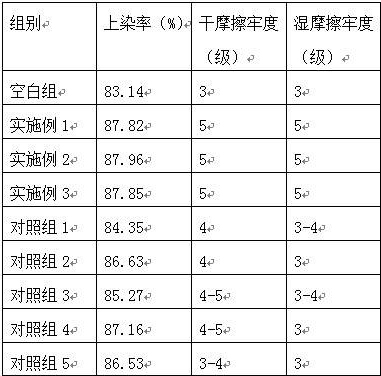

Examples

Embodiment 1

[0017] A pretreatment method for improving bamboo dyeing performance, comprising the following contents:

[0018] (1) Put the bamboo raw material in a hydrochloric acid aqueous solution with a mass concentration of 7%, vacuumize it to 0.07MPa, keep it for 25 minutes, pressurize it to 0.55MPa, and keep the pressure for 3.5 hours. Microwave treatment for 15 minutes under power conditions;

[0019] (2) Treat the bamboo after the above treatment at -10°C for 50 minutes;

[0020] (3) Place the frozen bamboo in a treatment agent at a temperature of 45°C, vacuumize to a negative pressure of 0.06MPa, keep it for 50 minutes, take it out, and set aside;

[0021] The treatment agent includes the following raw materials in parts by weight: 3 parts of propylene glycol methyl ether acetate, 8 parts of hydroxycarboxylic acid, 2 parts of siloxane coupling agent, 1.2 parts of 1,3-propyl sultone, 0.4 parts of sodium benzoate 0.2 parts of 2,3,5-trimethylpyrazine, 100 parts of water;

[0022] ...

Embodiment 2

[0027] A pretreatment method for improving bamboo dyeing performance, comprising the following contents:

[0028] (1) Put the bamboo raw material in an aqueous hydrochloric acid solution with a mass concentration of 8%, evacuate it to 0.06MPa, keep it for 30 minutes, pressurize it to 0.45MPa, and keep the pressure for 4 hours. Microwave treatment under power conditions for 18 minutes;

[0029] (2) Treat the bamboo after the above treatment at -10°C for 60 minutes;

[0030] (3) Place the frozen bamboo in a treatment agent at a temperature of 42°C, evacuate to a negative pressure of 0.06 MPa, keep it for 60 minutes, take it out, and set aside;

[0031] The treatment agent includes the following raw materials in parts by weight: 4 parts of propylene glycol methyl ether acetate, 10 parts of hydroxycarboxylic acid, 1 part of siloxane coupling agent, 1.6 parts of 1,3-propyl sultone, 0.2 parts of sodium benzoate 0.3 parts of 2,3,5-trimethylpyrazine, 100 parts of water;

[0032] (4...

Embodiment 3

[0037] A pretreatment method for improving bamboo dyeing performance, comprising the following contents:

[0038] (1) Put the bamboo raw material in an aqueous hydrochloric acid solution with a mass concentration of 8%, evacuate to 0.08MPa, keep it for 20 minutes, pressurize to 0.65MPa, and keep the pressure for 4 hours. Microwave treatment under power conditions for 12 minutes;

[0039] (2) Treat the bamboo after the above treatment at -10°C for 40 minutes;

[0040] (3) Place the frozen bamboo in a treatment agent at a temperature of 48°C, evacuate to a negative pressure of 0.06 MPa, keep it for 40 minutes, take it out, and set aside;

[0041] The treatment agent includes the following raw materials in parts by weight: 2 parts of propylene glycol methyl ether acetate, 6 parts of hydroxycarboxylic acid, 3 parts of siloxane coupling agent, 0.8 part of 1,3-propyl sultone, 0.6 part of sodium benzoate 0.1 part of 2,3,5-trimethylpyrazine, 100 parts of water;

[0042] (4) Place t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com