Method for extracting hemicellulose from lignocellulosic material

A lignocellulose and hemicellulose technology, applied in water/steam pretreatment, pulp by-product recovery, fermentation, etc., can solve the problems of separating hemicellulose, removing and retaining hemicellulose, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

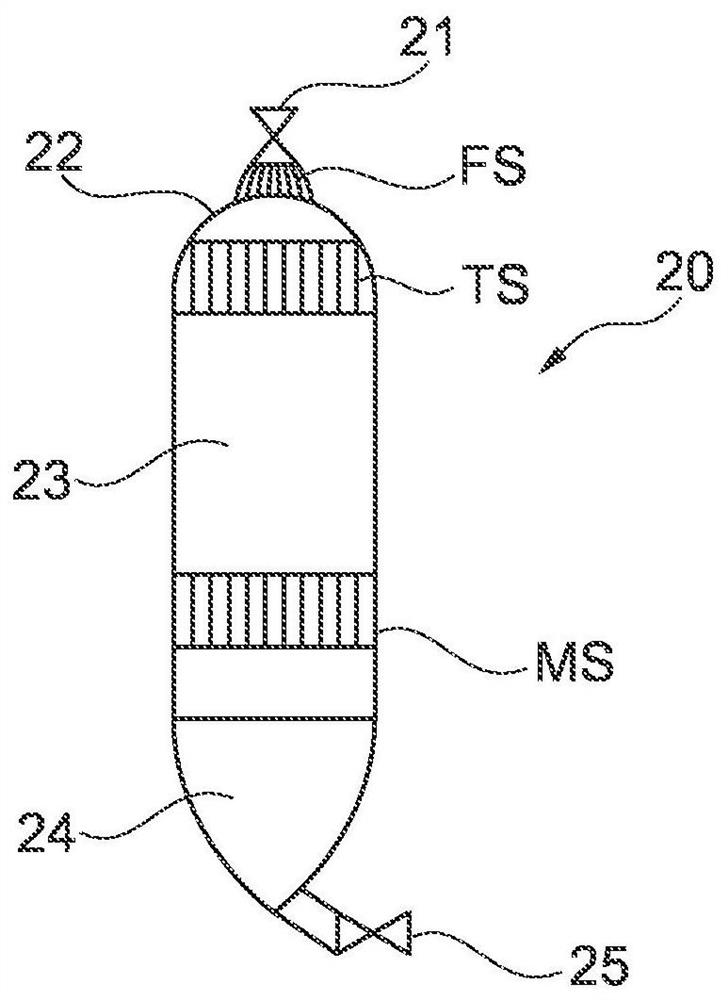

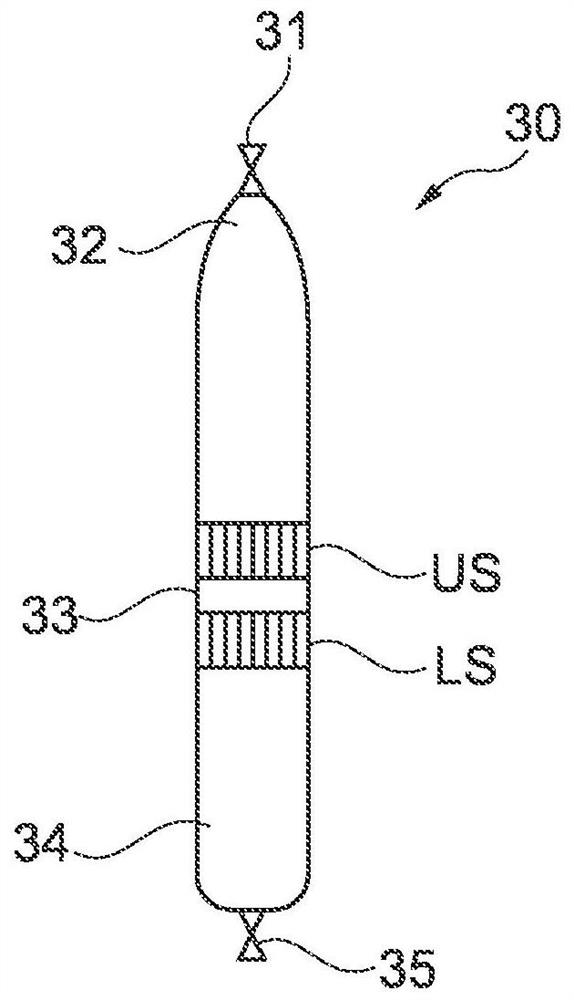

[0023] The method of the invention is described below, followed by one embodiment of applying the invention to a batch cooking process and one embodiment of applying the invention to a continuous cooking pulp process. The method is applicable to any process in which lignocellulosic material undergoes hydrolysis as part of the pulping process.

[0024] The term lignocellulosic material refers herein to material comprising lignin, cellulose and hemicellulose. One example of such a material is wood, others include other agricultural or forestry waste. Before the pulping process begins, the lignocellulosic material is usually divided into small pieces, chips or shreds.

[0025] When pulping from lignocellulosic materials, the process parameters are chosen so as to obtain a finished pulp of a defined quality in a cost- and time-saving manner as possible. Therefore, the mill has limited possibilities to change any process parameters, and the finished pulp is not allowed to deviate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com