Preparation method of interconnected layered porous carbon material for supercapacitor

A technology of supercapacitors and porous structures, which is applied in the manufacture of hybrid/electric double layer capacitors and electrodes of hybrid capacitors. It can solve the problems of high production costs, dead pores that cannot be connected to each other, and complicated preparation processes, and achieve high rate performance. Conducive to ion diffusion and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of preparation operation steps of interconnected layered porous structure carbon material for supercapacitor is as follows:

[0034] (1) Take the egg shell from which the egg white, egg yolk and egg film have been removed, heat-treat it in the air at 350°C for 3 hours, and the heating rate is 1°C / min, and then grind the obtained egg shell into a fine powder, The egg shell powder is obtained, and passed through a 40-mesh sieve.

[0035] (2) Add 2 g of egg shell powder and 4 g of agar powder into 80 ml of 5% polyvinylpyrrolidone aqueous solution, mix evenly at 85° C., and dry to obtain a mixture of egg shell and agar.

[0036] (3) In an inert atmosphere, carbonize the obtained mixture at a temperature of 900° C. for 2 hours to obtain carbides.

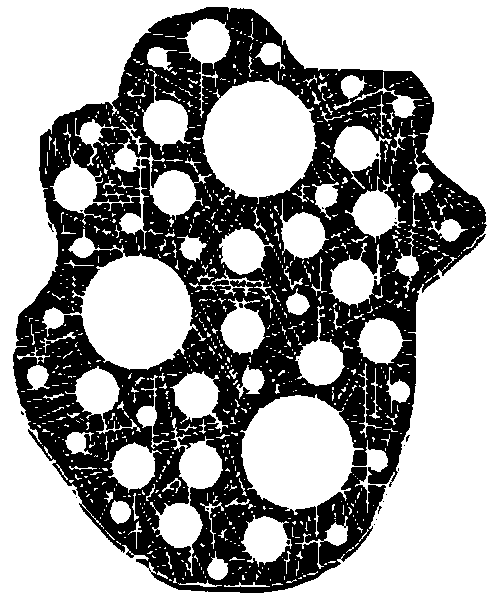

[0037] (4), pickling, washing and drying the carbides to obtain the interconnected layered porous structure carbon material of the present invention, see figure 1 .

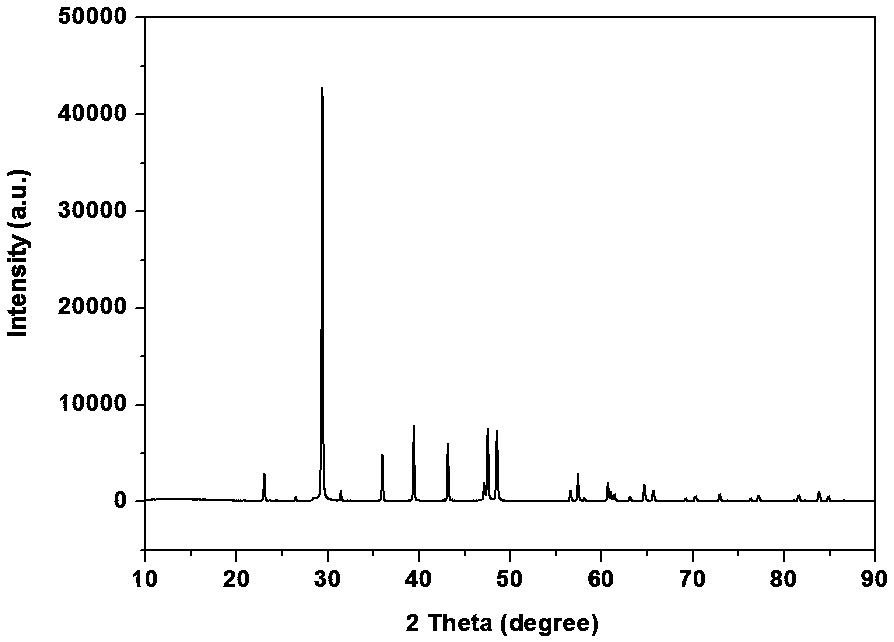

[0038] Carry out X-ray powder diffraction test on egg...

Embodiment 1

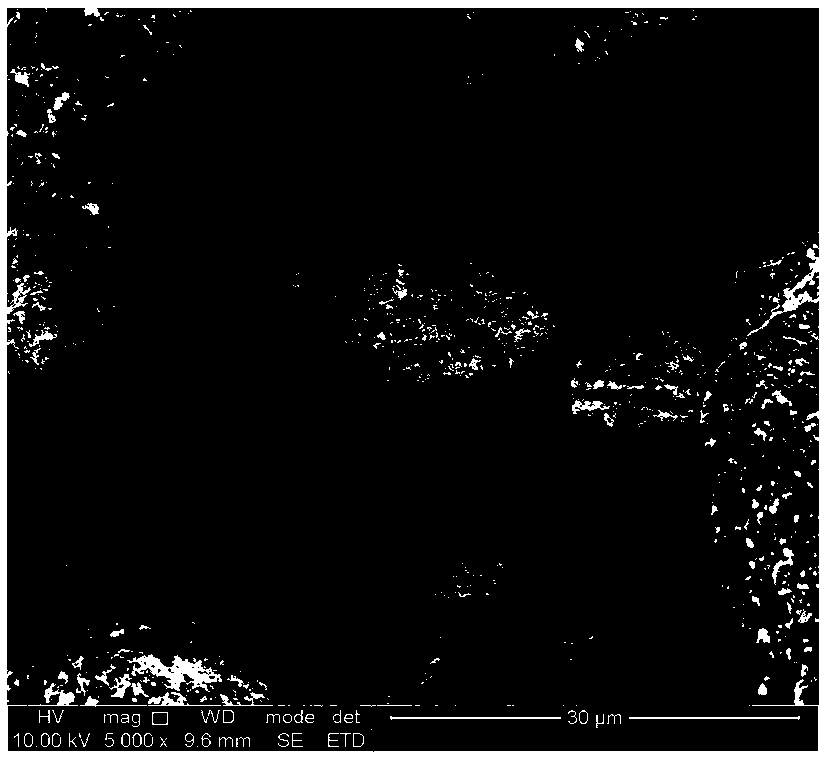

[0040] Carry out transmission electron microscope test to the carbon material that embodiment 1 makes, its test result is as follows Figure 4 As shown, it can be concluded from the figure that the prepared carbon material has a hierarchical porous structure.

[0041] The carbon material prepared in Example 1 was subjected to nitrogen adsorption and desorption experiments, and the test results showed that its specific surface area was 249 m 2 g -1 .

[0042] The carbon material prepared in Example 1 was subjected to an elemental analysis test, and the test result showed that its nitrogen content was 4.1%.

[0043] Electrochemical performance test:

[0044] The interconnected hierarchical porous carbon material prepared above is made into an electrode, and the electrochemical performance is tested. The specific process is as follows:

[0045] Weigh the active material, graphite, acetylene black, PVDF according to the mass percentage of 70:10:10:10, put them together and gr...

Embodiment 2

[0048] A kind of preparation operation steps of interconnected layered porous structure carbon material for supercapacitor is as follows:

[0049] (1) Take the egg shell from which the egg white, egg yolk and egg film have been removed, heat-treat it in the air at 350°C for 3 hours, and the heating rate is 1°C / min, and then grind the obtained egg shell into a fine powder, The egg shell powder is obtained, and passed through a 40-mesh sieve.

[0050] (2) Add 4 g of egg shell powder and 4 g of agar powder into 80 ml of 5% polyvinylpyrrolidone aqueous solution, mix evenly at 85° C., and dry to obtain a mixture of egg shell and agar.

[0051] (3) In an inert atmosphere, carbonize the obtained mixture at a temperature of 900° C. for 2 hours to obtain carbides.

[0052] (4) Carbide is pickled, washed and dried to obtain the interconnected hierarchical porous structure carbon material described in the present invention.

[0053] The carbon material prepared in Example 2 was subjected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com