Preparation method of high-wear-resistance crucible ceramic materials

A ceramic material, high wear-resistant technology, applied in the direction of crucible furnace, lighting and heating equipment, furnace type, etc., can solve the problems of rising metal melting cost, poor wear resistance, short service life, etc., achieve good molding rate and preparation method Simple, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

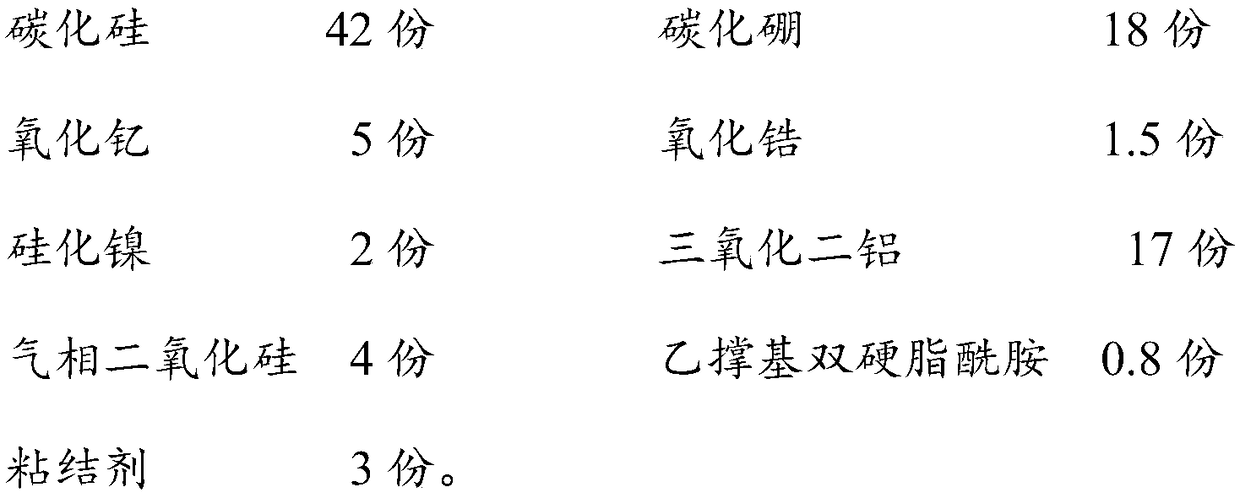

[0037] Blanks for crucibles, the blanks are composed of the following components by mass:

[0038]

[0039] Preparation method of high wear-resistant crucible ceramic material:

[0040] Accurately weigh the silicon carbide, boron carbide, yttrium oxide, zirconia, nickel silicide, aluminum oxide, fumed silica, ethylene bisstearamide and binder;

[0041] Put silicon carbide, boron carbide, yttrium oxide, zirconia, nickel silicide, aluminum oxide, and fumed silicon dioxide into a ball mill respectively, the ball-to-material ratio is 20:1, and the ball milling time is 250 minutes for grinding;

[0042] The pulverized silicon carbide, boron carbide, yttrium oxide, zirconia, nickel silicide, aluminum oxide, fumed silica and ethylene bisstearamide were dried in a drying oven at a drying temperature of 140°C. The time is 20 minutes;

[0043] Add the dried silicon carbide, boron carbide, yttrium oxide, zirconia, nickel silicide, aluminum oxide, fumed silica and ethylene bisstearam...

Embodiment 2

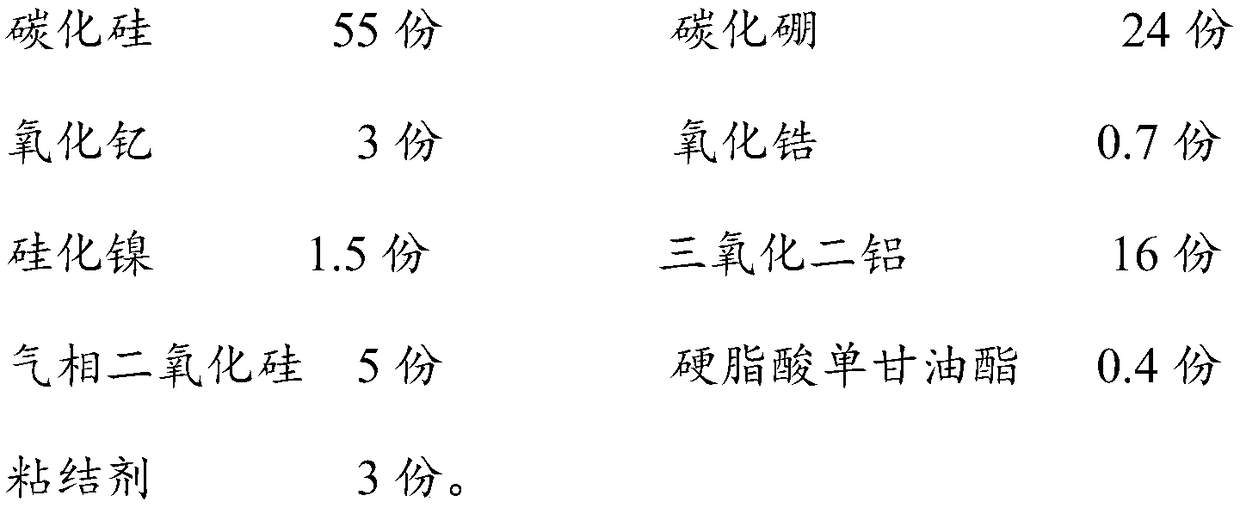

[0049] Blanks for crucibles, the blanks are composed of the following components by mass:

[0050]

[0051] Preparation method of high wear-resistant crucible ceramic material:

[0052] Accurately weigh the silicon carbide, boron carbide, yttrium oxide, zirconia, nickel silicide, aluminum oxide, fumed silica, monoglyceride stearate and binder in the formula quantity;

[0053] Put silicon carbide, boron carbide, yttrium oxide, zirconia, nickel silicide, aluminum oxide and fumed silicon dioxide into the ball mill respectively, the ball-to-material ratio is 28:1, and the ball milling time is 170min, then pulverize;

[0054] The pulverized silicon carbide, boron carbide, yttrium oxide, zirconia, nickel silicide, aluminum oxide, fumed silica and monoglyceride stearate were dried in a drying oven at a drying temperature of 135°C and a drying time of 23 minutes;

[0055] Add the dried silicon carbide, boron carbide, yttrium oxide, zirconia, nickel silicide, aluminum oxide, fumed...

Embodiment 3

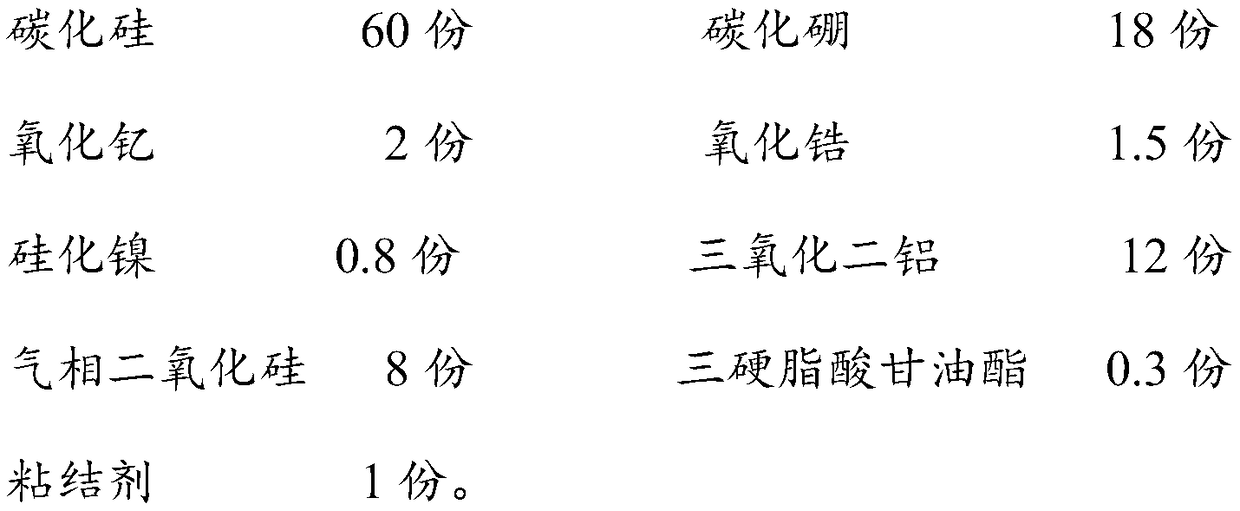

[0061] Blanks for crucibles, the blanks are composed of the following components by mass:

[0062]

[0063] Preparation method of high wear-resistant crucible ceramic material:

[0064] Accurately weigh the silicon carbide, boron carbide, yttrium oxide, zirconia, nickel silicide, aluminum oxide, fumed silica, glyceryl tristearate and binder in the formula quantity;

[0065] Put silicon carbide, boron carbide, yttrium oxide, zirconia, nickel silicide, aluminum oxide and fumed silicon dioxide into the ball mill respectively, the ball-to-material ratio is 30:1, the ball milling time is 150min, and pulverize;

[0066] Put the pulverized silicon carbide, boron carbide, yttrium oxide, zirconia, nickel silicide, aluminum oxide, fumed silicon dioxide, and glyceryl tristearate in a drying oven for drying at a drying temperature of 110°C and a drying time of 30min;

[0067] Add the dried silicon carbide, boron carbide, yttrium oxide, zirconia, nickel silicide, aluminum oxide, fumed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com