Palm mono-fiber micro-tube, capillary gas chromatographic column, and preparation and application thereof

A technology of gas chromatography column and capillary column, which is applied in the field of capillary gas chromatography column and its preparation and application, palm single fiber microtube, can solve the problems that there are no research reports on gas chromatography separation medium of biomass materials, and achieve high column efficiency, particle size The effect of uniform diameter distribution and rich functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] (1) peel off the palm fiber from the palm tree, rinse with deionized water to remove impurities, dry at 80°C for 12 hours, cut 50 grams of cleaned and dried palm fiber into 2-3cm long; then place the palm fiber at a concentration of In 5mol / L NaOH solution, react at 150°C for 16h, then cool to 25°C;

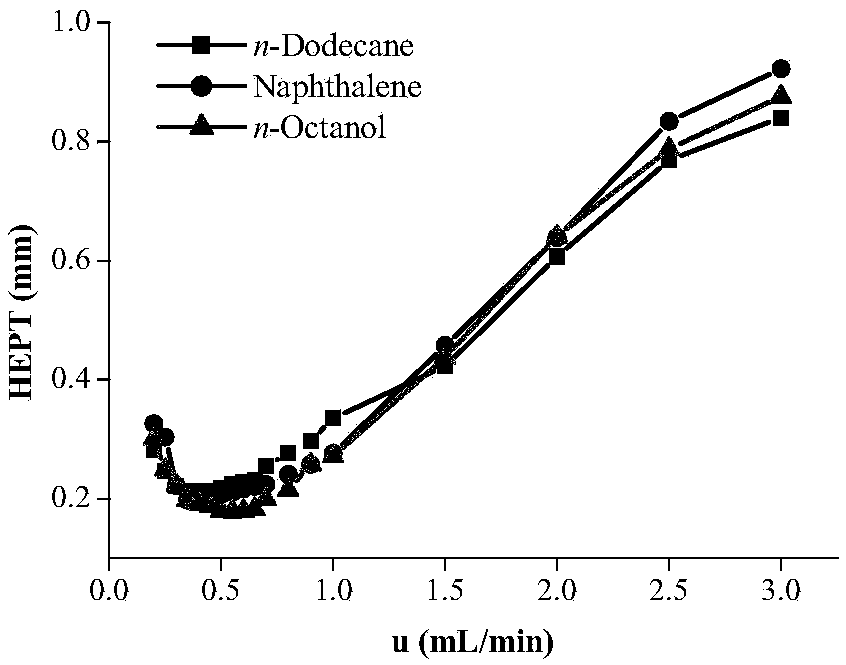

[0073] (2) Ultrasonic treatment of the mixed system after cooling in step (1) for 4h with ultrasonic power of 50KW, then use ionized water to wash 4 times to neutrality to obtain palm single fiber microtubes (SPFMs), see figure 1 , the surface of the prepared palm monofilament microtubules is rough and contains abundant pores, the particle size distribution is uniform, the functional groups are rich, and there are many pores, the surface has wrinkles, the diameter is 3-5 μm, and the pore size is about 1 μm;

[0074] (3) Quartz capillary column (10m×0.25mm i.d.) was treated with NaOH solution with a concentration of 1mol / L and HCl solution with a concentration of 0.1mol / L ...

Embodiment 2

[0079] (1) peel off the palm fiber from the palm tree, rinse with deionized water to remove impurities, dry at 80°C for 12 hours, cut 50 grams of cleaned and dried palm fiber into 1-2cm long; then place the palm fiber at a concentration of In 4mol / L NaOH solution, react at 180°C for 12h, then cool to 30°C;

[0080] (2) Ultrasonic treatment of the mixed system after cooling in step (1) with ultrasonic power of 60KW for 3h, and then use ionized water to wash 3 times to neutrality to obtain palm monofilament microtubules (SPFMs);

[0081] (3) Quartz capillary column (10m×0.25mm i.d.) was sequentially treated with NaOH solution with a concentration of 1mol / L and HCl solution with a concentration of 0.1mol / L for 35min, then cleaned to neutral, and dried at 220°C under a nitrogen atmosphere 8h, obtain the pretreated capillary column;

[0082] (4) Mix 110 μL tetraethylorthosilicate (TEOS), 220 μL polydimethylsiloxane, hydroxyl-blocked short (HO-TOS), 10 μL polymethylhydrogensiloxane...

Embodiment 3

[0086] (1) peel off the palm fiber from the palm tree, rinse with deionized water to remove impurities, dry at 80°C for 12 hours, cut 50 grams of cleaned and dried palm fiber into 3-5cm long; then place the palm fiber at a concentration of In 6mol / L NaOH solution, react at 130°C for 18h, then cool to 20°C;

[0087] (2) The mixed system after cooling in the step (1) is ultrasonically treated with ultrasonic power of 45KW for 5h, then adopts ionized water to wash 5 times to neutrality, obtains palm monofilament microtubules (SPFMs);

[0088] (3) Quartz capillary column (10m×0.25mm i.d.) was sequentially treated with NaOH solution with a concentration of 1mol / L and HCl solution with a concentration of 0.1mol / L for 40min, then cleaned to neutral, and dried at 180°C under a nitrogen atmosphere 12h, obtain the pretreated capillary column;

[0089] (4) Mix 110 μL tetraethylorthosilicate (TEOS), 220 μL polydimethylsiloxane, hydroxyl-blocked short (HO-TOS), 10 μL polymethylhydrogensil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com