Novel fluoro-silicone coating preventing pollution flashover and a preparing method thereof

An anti-pollution flashover coating and fluorosilicon technology, applied in the coating field, can solve the problem that the anti-pollution flashover coating cannot meet the needs of the power system, etc., and achieve the effects of excellent hydrophobic migration, easy drying and easy molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

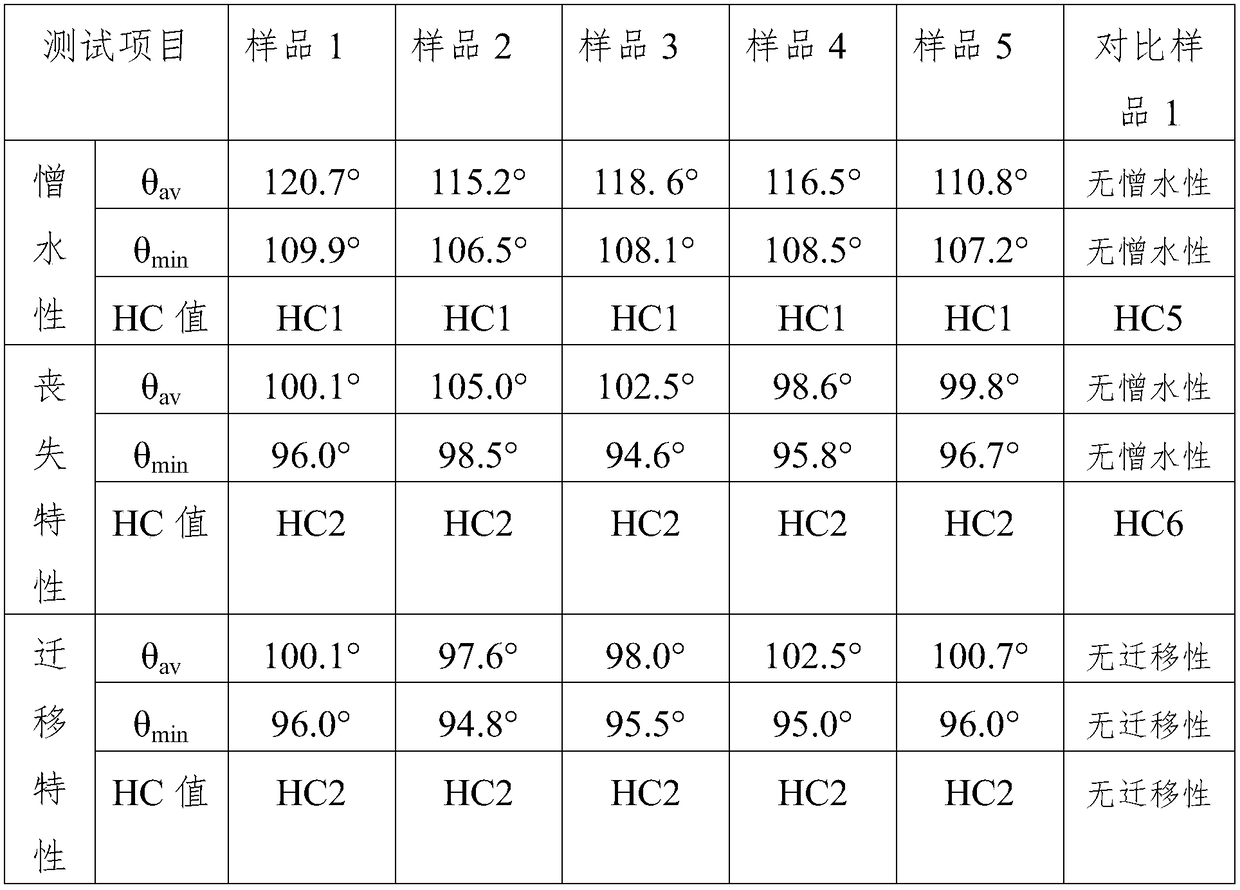

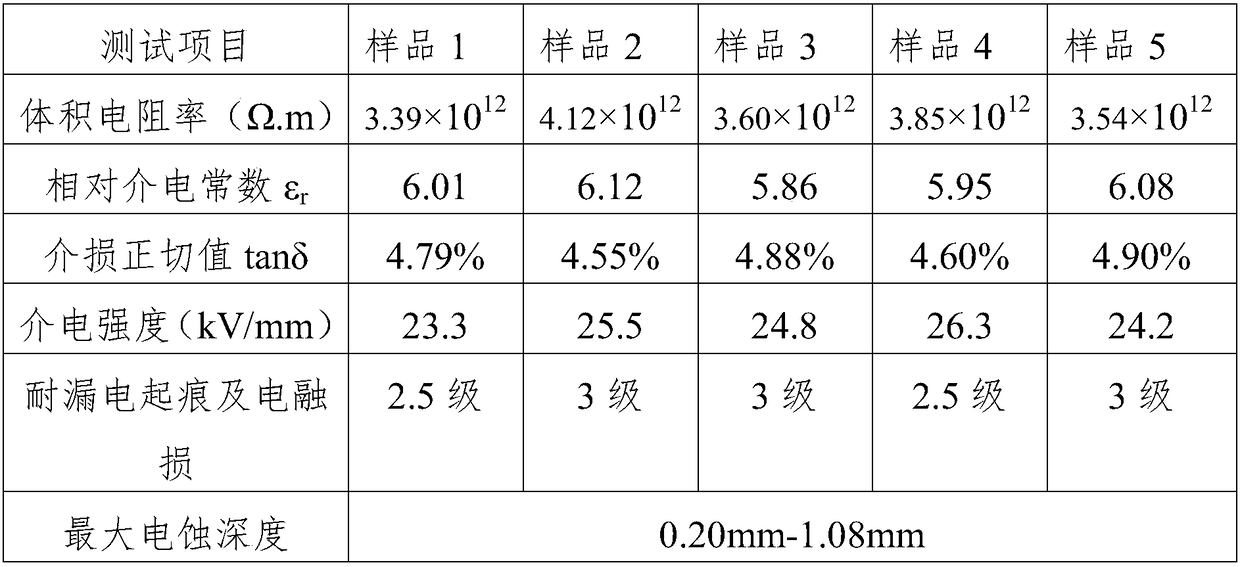

Examples

Embodiment 1

[0033] The fluorosilicone antifouling flashover coating of the present embodiment comprises the following components in parts by weight: 25 parts of tetrafluoropropyl methacrylate, 5 parts of hydroxyethyl methacrylate, 2 parts of butyl methacrylate, 1 part of methyl acrylate, 1 part of isooctyl methacrylate, 10 parts of vinyltriethoxysilane, 5 parts of γ-methacryloxypropyl trimethoxysilane, 5 parts of heptamethyltrisiloxane parts, 4 parts of polydimethylsiloxane, 4 parts of hydroxyl silicone oil, 0.6 parts of azobisisobutyronitrile, and 20 parts of dimethyl carbonate.

[0034] The fluorosilicone antifouling flashover coating of the present embodiment is prepared by the following method:

[0035]Under normal temperature conditions, add acrylate monomer, silane coupling agent, polysiloxane, 2 / 3 weight initiator and solvent, blow nitrogen for 30 minutes to remove the oxygen in the system; continue to blow nitrogen, then raise the temperature of the oil bath to 80±2°C, stir and r...

Embodiment 2

[0037] The fluorosilicone antifouling flashover coating of this embodiment comprises the following components in parts by weight: 10 parts of tetrafluoropropyl methacrylate, 30 parts of octafluoropentyl methacrylate, and 5 parts of hydroxyethyl methacrylate , 5 parts of butyl methacrylate, 10 parts of methyl methacrylate, 10 parts of isooctyl methacrylate, 28 parts of vinyl triethoxysilane, 4 parts of γ-methacryloxypropyl trimethoxysilane 8 parts, 8 parts of heptamethyltrisiloxane, 4 parts of polydimethylsiloxane, 6 parts of hydroxyl silicone oil, 1.2 parts of methyl ethyl ketone peroxide, and 30 parts of acetone.

[0038] The preparation method of the fluorosilicone antifouling flashover coating of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0040] The fluorosilicone antifouling flashover coating of the present embodiment comprises the following components in parts by weight: 10 parts of dodecafluoroheptyl methacrylate, 20 parts of hydroxyethyl methacrylate, 5 parts of butyl methacrylate, 5 parts of methyl methacrylate, 10 parts of isooctyl methacrylate, 15 parts of vinyltriethoxysilane, 2 parts of γ-methacryloxypropyl trimethoxysilane, heptamethyltrisiloxane 3 parts, 2 parts of polydimethylsiloxane, 0.2 parts of lauroyl peroxide, 10 parts of ethyl acetate.

[0041] The preparation method of the fluorosilicone antifouling flashover coating of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com