Anti-blue ray optical resin and preparation method thereof

An optical resin and anti-blue light technology, which is applied in the field of optical resin, can solve the problems of color blindness, low selective transmittance of long-wave visible light, and inability to be durable, and achieve the effect of improving dispersion and excellent anti-blue light performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

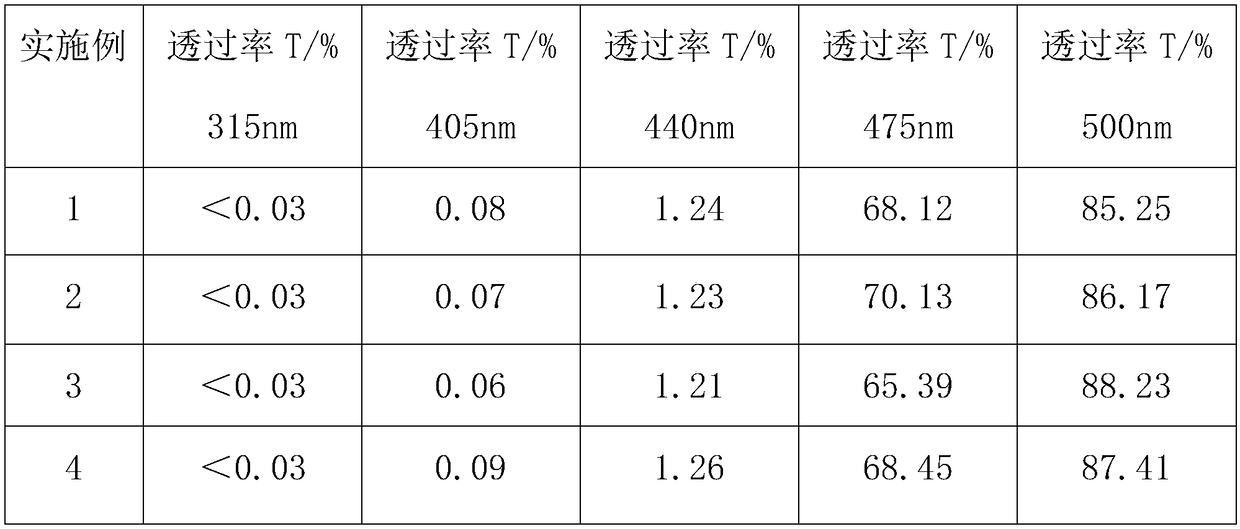

Examples

Embodiment 1

[0015] A kind of anti-blue light optical resin, its raw material comprises: be used for making the ethoxylated bisphenol A di(meth)acrylate of optical material, modified TiO 2 Nanoparticles, UV-P and tert-butyl peroxy 2-ethylhexyl carbonate; among them, modified TiO 2 Nanoparticles are 1 wt% of ethoxylated bisphenol A di(meth)acrylate, UV-P is 2 wt% of ethoxylated bisphenol A di(meth)acrylate, tert-butyl peroxy 2-ethylhexyl carbonate The ester is 0.1 wt% of ethoxylated bisphenol A di(meth)acrylate;

[0016] The method for preparing the modified metal oxide nanoparticles includes: placing the metal oxide nanoparticles in absolute ethanol, ultrasonically vibrating for 1 hour, filtering, washing with absolute ethanol, and drying to obtain purified metal oxide nanoparticles; The purified metal oxide nanoparticles and methacrylic acid are placed in toluene solvent, the mass ratio of metal oxide nanoparticles and methacrylic acid is 1:60, ultrasonically oscillated for 1h, then stir...

Embodiment 2

[0019] An anti-blue light optical resin, the raw materials of which include: acrylate polymer monomers for making optical materials, modified metal oxide nanoparticles, ultraviolet absorbers and initiators; wherein the modified metal oxide nanoparticles are 5wt% of the acrylate macromolecular monomer, the ultraviolet absorber is 0.2wt% of the acrylate macromolecular monomer, and the initiator is 0.5wt% of the acrylate macromolecular monomer;

[0020] The method for preparing the modified metal oxide nanoparticles includes: placing the metal oxide nanoparticles in absolute ethanol, ultrasonically vibrating for 2 hours, filtering, washing with absolute ethanol, and drying to obtain purified metal oxide nanoparticles; The purified metal oxide nanoparticles and methacrylic acid were placed in toluene solvent, the mass ratio of metal oxide nanoparticles and methacrylic acid was 1:40, ultrasonically oscillated for 2 hours, stirred and reacted at 50°C for 12 hours, filtered and washed...

Embodiment 3

[0024] An anti-blue light optical resin, the raw materials of which include: acrylate polymer monomers for making optical materials, modified metal oxide nanoparticles, ultraviolet absorbers and initiators; wherein the modified metal oxide nanoparticles are 3wt% of the acrylate macromolecular monomer, the ultraviolet absorber is 1wt% of the acrylate macromolecular monomer, and the initiator is 0.3wt% of the acrylate macromolecular monomer;

[0025] The method for preparing the modified metal oxide nanoparticles includes: placing the metal oxide nanoparticles in absolute ethanol, ultrasonically oscillating for 1.5 hours, filtering, washing with absolute ethanol, and drying to obtain purified metal oxide nanoparticles; The purified metal oxide nanoparticles and methacrylic acid were placed in toluene solvent, the mass ratio of metal oxide nanoparticles and methacrylic acid was 1:50, ultrasonically oscillated for 1.5h, then stirred and reacted at 55°C for 10h, filtered , washed, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com