High performance alumina composite ceramic cutting tool material and preparation method thereof

A technology of composite ceramics and cutting tool materials, which is applied in the field of new materials, can solve problems such as the limitation of mechanical properties of materials, and achieve the effect of improving comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

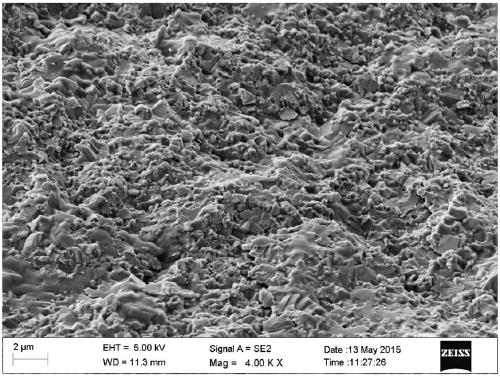

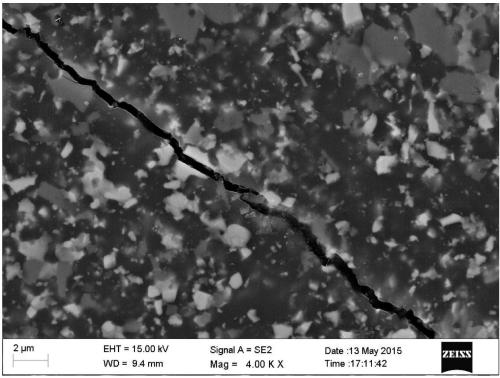

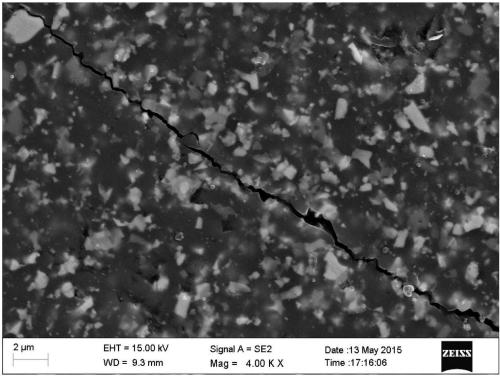

Image

Examples

Embodiment 1

[0042] Carry out batching according to mass percentage, take by embodiment parameter attached table: the total amount of aluminum oxide powder is 65~55%; The total amount of titanium carbonitride powder is 20%, and the total amount of tungsten carbide titanium powder is 15~25%; The aluminum oxide powder, titanium carbonitride powder, and tungsten carbide titanium powder are poured into the mixing tank in proportion, and absolute ethanol is added as the medium, and ball milled on a ball mill for 48 hours to make the materials of each phase mix more evenly, and then vacuum dried , and sieve to obtain a well-dispersed composite ceramic material powder, which is packaged for later use. Put the mixed composite ceramic material powder into a graphite mold, and use a uniformly pressurized hot-press sintering process in a vacuum environment; start heating from room temperature to 1650°C, and the heating rate is 50°C / min, and the pressure is pre-increased to 4Mpa; the subsequent pressu...

Embodiment 2

[0047] 1) Using absolute ethanol as the medium, separate ball milling of alumina, titanium carbonitride and tungsten carbide titanium raw material powders, the ball milling process is carried out on a cylinder ball mill, wherein the alumina powder is ball milled for 65 hours to break up a larger The agglomerated particles were obtained to obtain a more uniform powder with a particle size of 0.5 μm; titanium carbonitride powder was ball milled for 65 hours to break up larger agglomerated particles to obtain a more uniform powder with a particle size of 0.5 μm; titanium tungsten carbide powder Ball milling for 230 hours to reduce the particle size of the powder to 0.5 μm, and then vacuum-dried, sieved, and packaged for later use;

[0048] 2) Pour 50 parts by weight of alumina powder with a particle size of 0.5 μm, 15 parts by weight of titanium carbonitride powder with a particle size of 0.5 μm, and 15 parts by weight of tungsten carbide titanium powder with a particle size of 0....

Embodiment 3

[0052] 1) Using absolute ethanol as the medium, separate ball milling of alumina, titanium carbonitride and tungsten carbide titanium raw material powders, the ball milling process is carried out on a cylinder ball mill, wherein the alumina powder is ball milled for 65-79 hours to break up Larger agglomerated particles to obtain a more uniform powder with a particle size of 1.0 μm; titanium carbonitride powder ball milled for 72 hours to break up larger agglomerated particles to obtain a more uniform powder with a particle size of 1.0 μm; tungsten carbide Titanium powder was ball milled for 240 hours to reduce the powder particle size to 1.0 μm, after which it was vacuum dried, sieved, and packaged for later use;

[0053] 2) Pour 60 parts by weight of alumina powder with a particle size of 1.0 μm, 20 parts by weight of titanium carbonitride powder with a particle size of 1.0 μm, and 20 parts by weight of tungsten carbide titanium powder with a particle size of 1.0 μm into a mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com