Precipitation hardening stainless steel PH17-4 negative temperature gradient aging heat treatment method

An aging heat treatment and precipitation hardening technology, applied in the field of aging heat treatment, can solve the problem of not being able to give full play to the comprehensive mechanical properties, and achieve the effect of improving the comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

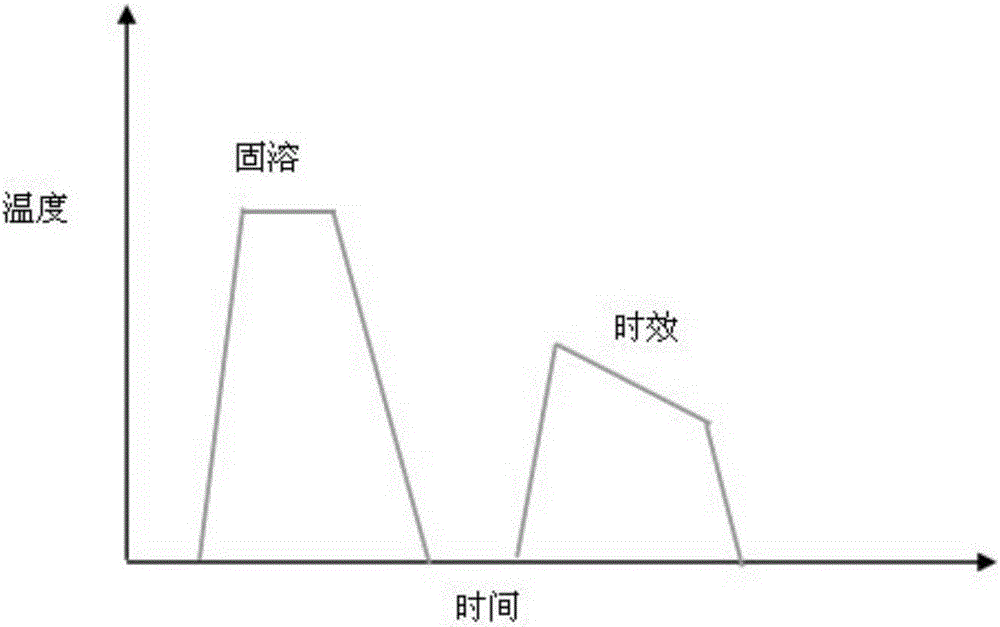

[0013] Specific embodiment one: a kind of precipitation hardening stainless steel PH17-4 negative temperature gradient aging heat treatment method of this embodiment, it is realized through the following steps:

[0014] After the precipitation hardening stainless steel is solution treated, the sample is heated to 400-650°C, and the aging treatment is carried out in the mode of negative aging temperature gradient of 16-80°C / h for 1-5h, and then air-cooled or air-cooled to room temperature, That is, the above-mentioned precipitation hardening stainless steel PH17-4 negative temperature gradient aging heat treatment is completed.

specific Embodiment approach 2

[0015] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the sample is heated to 500°C to 620°C, and the negative aging temperature gradient is 80°C / h, the aging treatment is 1h, and then air-cooled or air-cooled to room temperature. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 is that the sample is heated to 500°C-620°C, and the negative aging temperature gradient is 70°C / h, and the aging treatment is 1h, and then air-cooled or air-cooled to room temperature. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com