A method for denitrification of low-concentration ammonia nitrogen wastewater based on adsorption-regeneration and anaerobic ammonium oxidation

An anaerobic ammonia oxidation and low-concentration ammonia nitrogen technology is applied in the field of denitrification treatment of low-concentration ammonia nitrogen wastewater, which can solve the problems of large amount of alkali dosage, biofilm influence, damage, etc., so as to improve treatment efficiency, reduce treatment costs, and achieve economical The effect of reliable technical means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

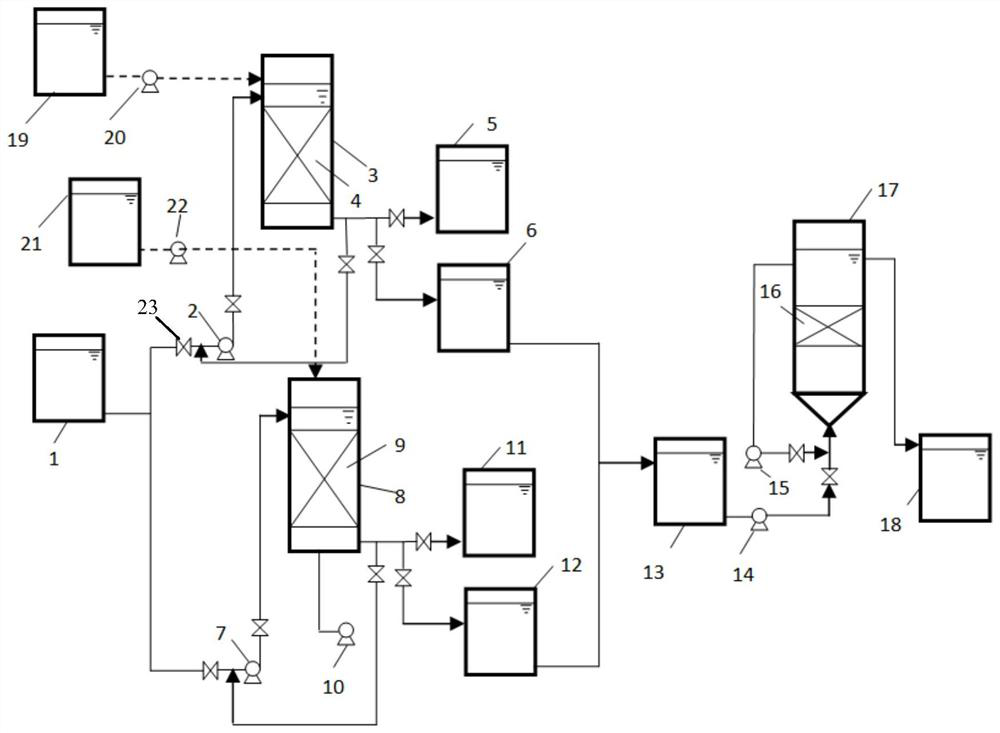

[0050] A low-carbon denitrification method for low-concentration ammonia-nitrogen wastewater based on adsorption-desorption, comprising the following steps:

[0051] (1) Take a fixed-bed reaction column filled with natural zeolite and have an effective volume of 1.0L and 3.0L respectively, wherein the 1.0L column is used as an adsorption materialization desorption column, and the 3.0L column is an adsorption biochemical regeneration column. Add 300mL of nitrification sludge with a sludge concentration of 3000mg / L, add ammonia nitrogen (such as: ammonium chloride) at a temperature of 24°C, and a dissolved oxygen of 0.1-1.0mg / L. The concentration of ammonia nitrogen is 50mg. / L, add sodium bicarbonate, the concentration of sodium bicarbonate is about 600mg / L, and after 8 hours of stuffy exposure, the film is successfully formed on the fixed bed;

[0052] (2) Pass waste water with an ammonia nitrogen concentration of 15mg / L into the adsorbate desorption column and the adsorption ...

Embodiment 2

[0060] A low-carbon denitrification method for low-concentration ammonia-nitrogen wastewater based on adsorption-desorption, comprising the following steps:

[0061] (1) Take a fixed-bed reaction column filled with natural zeolite and have an effective volume of 0.5L and 5.0L respectively, wherein the 0.5L column is used as an adsorption materialization desorption column, and the 5.0L column is an adsorption biochemical regeneration column. Add 500mL of nitrification sludge with a sludge concentration of 5000mg / L, add ammonia nitrogen (such as: ammonium chloride) at a temperature of 28°C, and a dissolved oxygen of 0.5-2.0mg / L. The concentration of ammonia nitrogen is 50mg / L, add sodium bicarbonate, the concentration of sodium bicarbonate is about 800mg / L, after 12 hours of stuffy exposure, the fixed bed is successfully formed;

[0062] (2) The wastewater with an ammonia nitrogen concentration of 50mg / L is passed into the adsorption desorption column and the adsorption biochem...

Embodiment 3

[0070] A low-carbon denitrification method for low-concentration ammonia-nitrogen wastewater based on adsorption-desorption, comprising the following steps:

[0071] (1) Take a fixed-bed reaction column filled with artificial zeolite and have an effective volume of 1.0L and 3.0L respectively, wherein the 1.0L column is used as an adsorption materialization desorption column, and the 3.0L column is an adsorption biochemical regeneration column. Add 100mL of nitrification sludge with a sludge concentration of 8000mg / L, add ammonia nitrogen (such as: ammonium chloride) at a temperature of 30°C, and a dissolved oxygen of 1.0-4.0mg / L. The concentration of ammonia nitrogen is 100mg. / L, add sodium bicarbonate, the concentration of sodium bicarbonate is about 1000mg / L, after 24 hours of stuffy exposure, the fixed bed is successfully formed;

[0072] (2) Pass waste water with an ammonia nitrogen concentration of 80mg / L into the adsorption desorption column and the adsorption biochemic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com