Preparation method and application of flexible catalytic material for water electrolysis

A catalytic material, a technology for electrolyzing water, applied in chemical instruments and methods, electrolysis process, electrolysis components, etc., can solve the problems of increased electron transport resistance, unstable catalytic effect, reduced catalytic activity, etc. Convenience and the effect of increasing catalytic sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1. Preparation of Co-PBA nanoparticles

[0049] The preparation of cobalt-like Prussian blue particles (Co-PBA) includes two steps of synthesis and purification.

[0050] Accurately weigh 0.15 mmol of cobalt acetate and dissolve in 40 ml of water to obtain A solution. At the same time, 0.08 mmol of potassium hexacyanocobaltate was accurately weighed and dissolved in 40 ml of water, and PVP was added while stirring to obtain solution B. Slowly add solution A to solution B while stirring (about 10 minutes after the addition), the solution gradually changes from colorless to pink, and continue stirring for 10 minutes after all the addition is completed. The above mixture was left to stand for 4 hours, immediately washed with water and ethanol by centrifugation for several times to remove residual impurities, and then freeze-dried for future use.

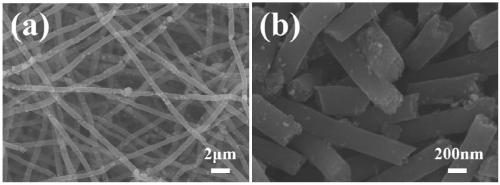

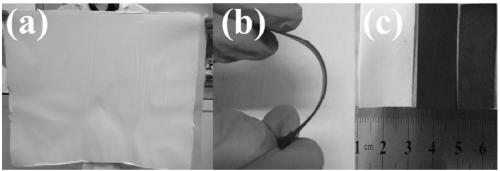

[0051] 2. Preparation of Co-PB / PAN nanofiber membrane

[0052] Accurately weigh 0.584g of the above-mentioned nanoparticles ...

Embodiment 2

[0061] Referring to the method of Example 1, the proportion of Co-PB doped in the nanofiber was changed (the proportions of Co-PB and PAN were respectively 0%, 3% and 5%), and other conditions remained unchanged.

[0062] The experimental results show that the doping of cobalt-based Prussian blue analog nanoparticles in the nanofibers promotes electron transfer and mass transfer, increases the catalytic sites, and is beneficial to improve the electrocatalytic performance. The experimental results are shown in the attached Figure 4 shown.

Embodiment 3

[0064] Referring to the method of Example 1, the above-mentioned Co-based carbon nanocomposite fiber was used as the catalytic working electrode, platinum was used as the counter electrode, Ag / AgCl was used as the reference electrode, and 0.5M sulfuric acid solution was used as the electrolyte for three-electrode electrocatalytic testing.

[0065] The experimental results show that the catalyst has good electrocatalytic performance in electrolysis of water under both acidic and alkaline conditions, and the electrocatalytic hydrogen production performance under alkaline conditions is better than that under acidic conditions, and the electrocatalytic oxygen production performance under acidic conditions is better than that under acidic conditions. Better than under acidic conditions, the experimental results are as attached Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com