Antibacterial coating of magnesium-based tissue engineering material and preparation method thereof

A technology of tissue engineering and antibacterial coating, which is applied in the field of antibacterial coating of magnesium-based tissue engineering materials and its preparation, can solve the problems of reducing the corrosion rate of porous magnesium and magnesium alloys, and the inability to effectively antibacterial, so as to solve bacterial infection and excellent sterilization Anti-inflammatory properties, osteogenic and angiogenic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

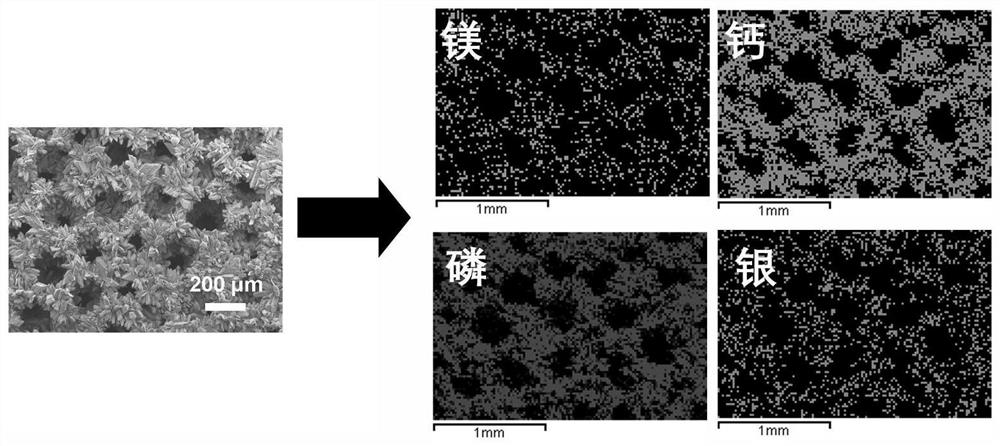

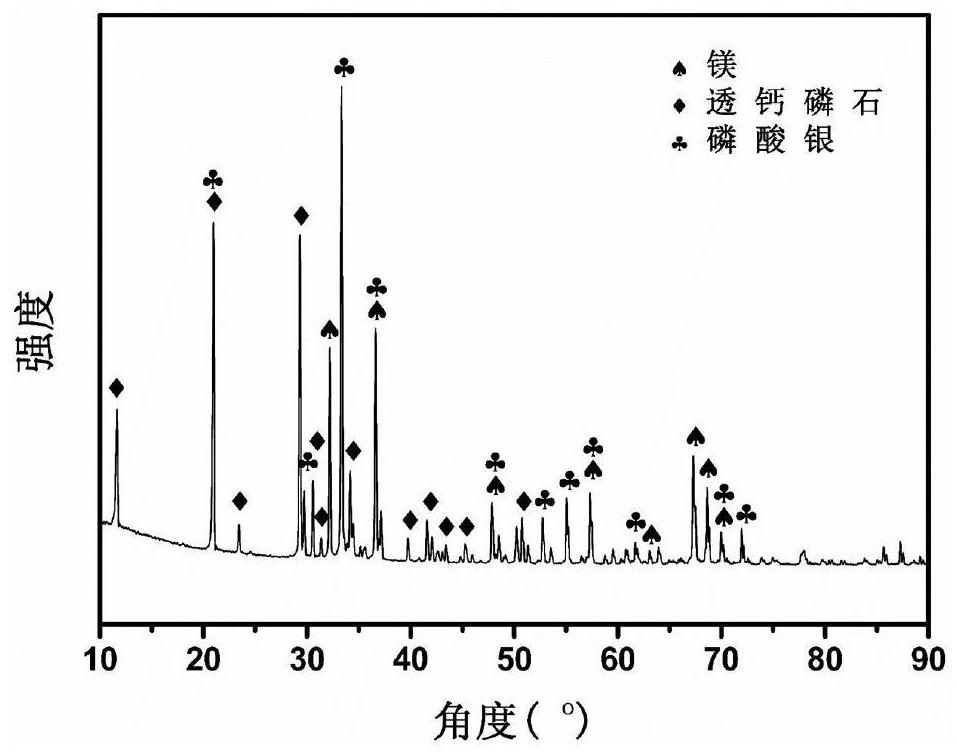

[0049] Preparation of antibacterial bioactive calcium-phosphorus-loaded nano-silver compound antibacterial bioactive coating on the surface of porous pure magnesium for tissue engineering, its structure is shown in the appendix figure 1 . During preparation, the porous pure magnesium is first made into The samples were ultrasonically cleaned with absolute ethanol and acetone for 5 min, respectively, and dried. Put the sample into CaHPO 4 :NaOH=8:2(wt.%) Soak in a water bath at a constant temperature (20°C) for 48h, take it out, wash it twice with ultrapure water, and blow dry. Immerse the porous pure magnesium sample coated with calcium phosphorus coating in 0.1mM silver chlorate solution to avoid light for 6 hours, take it out, wash it twice with ultrapure water, and dry it to get the antibacterial bioactive calcium Phosphorus loaded nano-silver compound coating. The scanning electron microscope observed that the thickness of the Ca-P coating was about 50 μm, and the ato...

Embodiment 2

[0051] Preparation of bioactive calcium phosphorus-supported nano-copper compound antibacterial bioactive coating on the surface of porous AZ31 (Mg-Al system) alloy. First, the porous AZ31 magnesium alloy is made into The samples were ultrasonically cleaned with absolute ethanol and acetone for 10 min, respectively, and dried. Put the sample into Ca(H 2 PO 4 ) 2 : NaOH=9:1 (wt.%) solution soaked at 25 ℃ for 10h, after taking out, washed twice with ultrapure water, and dried to obtain calcium phosphorus coating. Immerse the porous AZ31 alloy sample coated with calcium phosphorus coating in 0.8mM copper nitrate solution to avoid light and ultrasonic reaction for 3 hours, take it out, wash it twice with ultrapure water, and dry it to get the antibacterial bioactive calcium Phosphorus-loaded nano-copper compound coating. The scanning electron microscope observed that the thickness of the Ca-P coating was about 20 μm, and the atomic ratio of Ca / P was 1:1. The nano-copper comp...

Embodiment 3

[0053] Preparation of bioactive calcium-phosphorus-supported nano-zinc compound coating for antibacterial on the surface of porous Mg-Nd-Zn-Zr alloy. The porous Mg-Nd-Zn-Zr magnesium alloy is made into The samples were ultrasonically cleaned with absolute ethanol and acetone for 10 min, respectively, and dried. The sample was soaked in a 20% HF solution in a water bath at a constant temperature (20°C) for 8 hours, washed with deionized water and absolute ethanol successively, and dried. The fluorinated sample was then placed in Ca(NO 3 ) 2 :(NH 4 ) 2 HPO 4 =6.2:3.8 (wt.%) soaked in the solution of 4 ℃ for 6h, washed twice with ultrapure water after taking out, and dried to obtain a bioactive calcium-phosphorus composite coating. Immerse the porous Mg-Nd-Zn-Zr alloy coated with calcium-phosphorus coating in 5.0mM zinc nitrate solution to avoid light and shake for 10 minutes, take it out, wash it twice with ultrapure water, and dry it to get the Antibacterial bioactive c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com