Space three-dimensional dust control and removal method for dust produced during bracket moving of fully mechanized mining face

A fully mechanized mining face and space technology, applied in dust prevention, mining equipment, mining equipment, etc., can solve problems such as dust pollution, high wind speed, and large working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

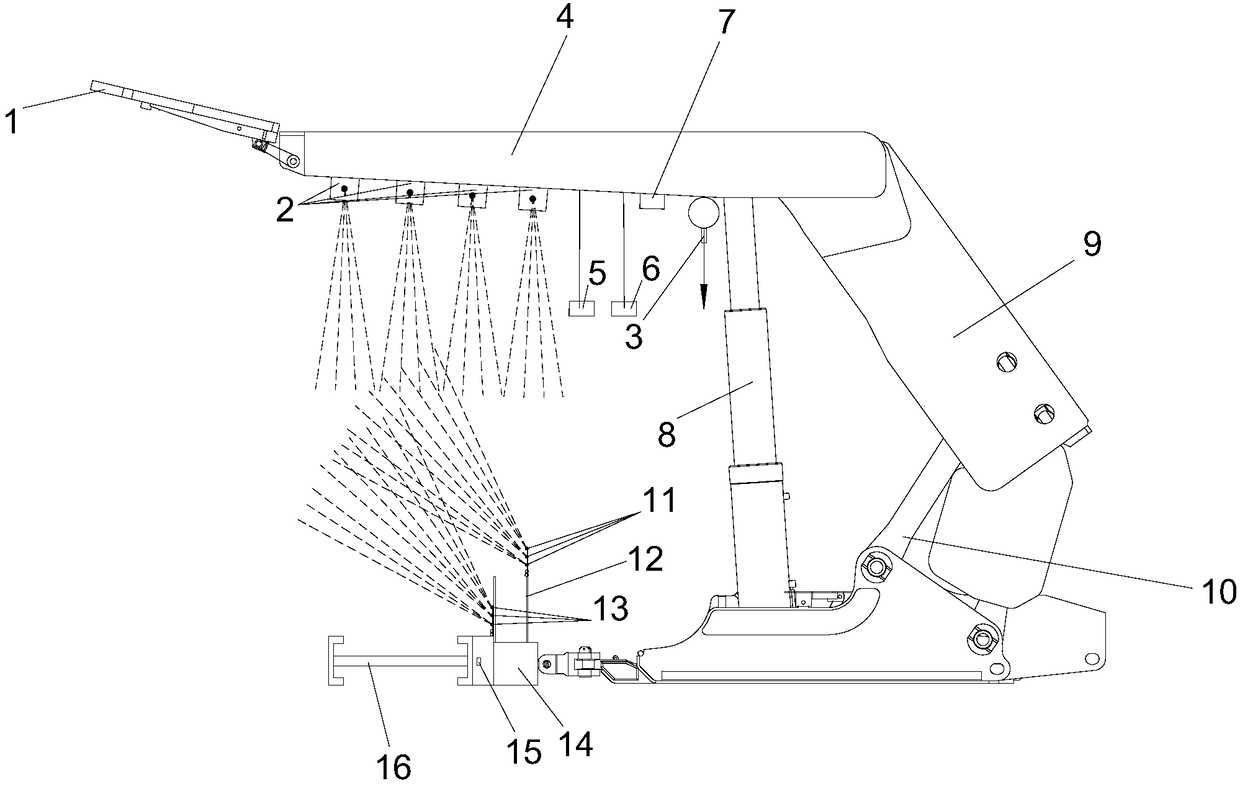

[0032] The present invention provides a spatial three-dimensional control dust removal method for dust production in fully mechanized mining working faces. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0033] The invention provides a three-dimensional control dust removal method for dust production in fully mechanized mining face, such as Figure 5As shown, it includes the following steps:

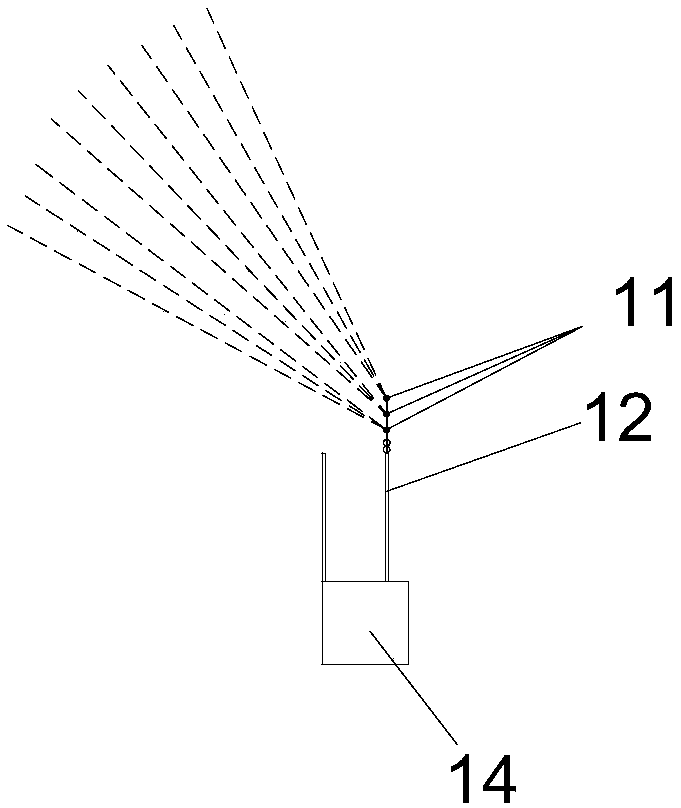

[0034] The air curtain machine is arranged along the width direction of the top of each hydraulic support, and the air flow is sprayed to form an air curtain, which isolates the hydraulic support from the space in front, detects the wind speed through the wind speed sensor 5, and sends the signal to the frequency c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com