460MPa grade cold-rolled microalloy high strength steel, and manufacturing method thereof

A high-strength steel, 460mpa technology, applied in the field of steel production and research, can solve the problems of weldability, poor rebound performance, small rebound deformation, etc., and achieve excellent rebound performance, good formability, and significant social and economic benefits. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

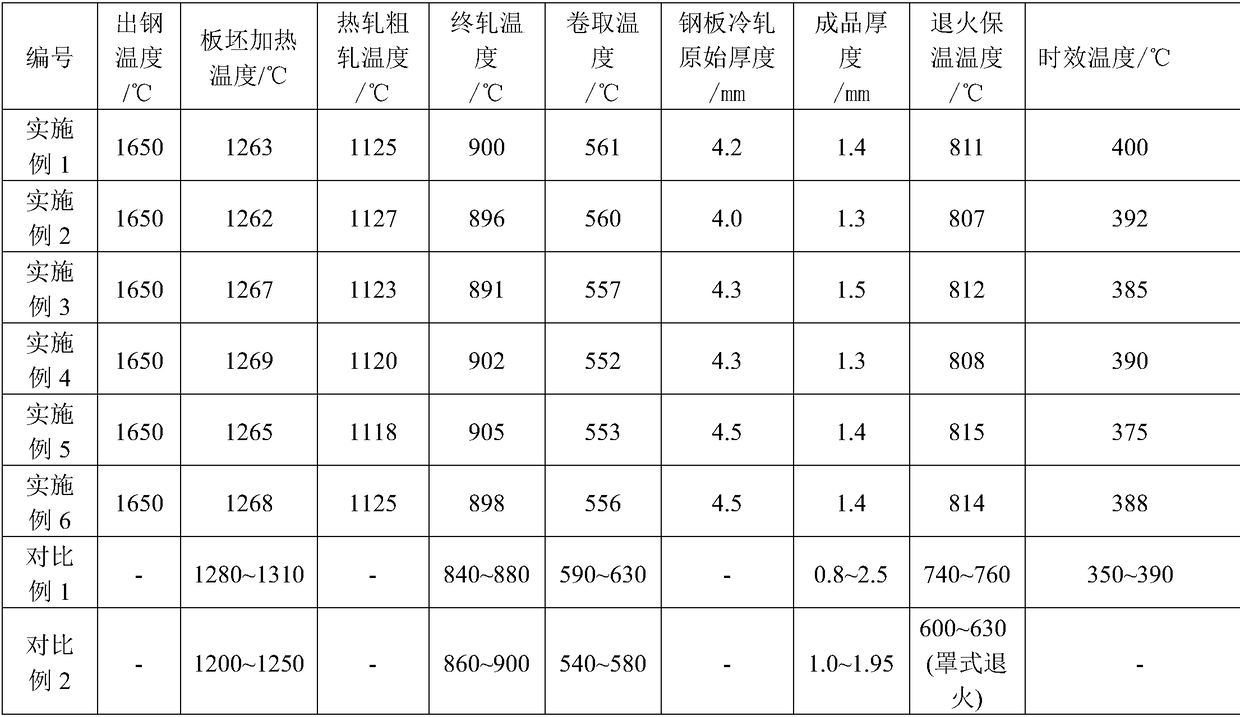

[0042] In order to better explain the present invention, the main content of the present invention is further clarified below in conjunction with specific examples, but the content of the present invention is not limited to the following examples.

[0043] Each embodiment of the present invention is produced according to the following steps:

[0044] 1) Converter steelmaking: smelting is carried out according to the design composition described in Table 1, and after the top-bottom compound blowing test steel of the industrial converter, considering the requirements of this steel type and the needs of large-scale production, the target temperature of tapping is set at about 1650°C. The bottom of the top-bottom compound blowing converter originally used 4 pieces of pinhole type air-permeable bricks. In order to reduce the content of molten steel [O] at the end of blowing, the number of air-permeable bricks was increased to 6 pieces; the furnace shape was also reasonably controlle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com