Resin microsphere plugging agent and preparation method therefor

A technology of resin microspheres and plugging agents, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of water-flooding wave volume and recovery rate reduction, formation pores and fractures becoming larger, and crude oil production impact. , to achieve the effect of geological improvement, oil production increase and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The preparation method of above-mentioned resin microsphere plugging agent, comprises the following steps:

[0061] A. Add organic dispersant and inorganic dispersant to deionized water, raise the temperature, control the stirring temperature to 60-70°C, and stir for 1 hour;

[0062] B. adding the oil-soluble initiator to the mixture of vinyl monomers, ester monomers and functional monomers to dissolve the oil-soluble initiator;

[0063] C. Add the mixture obtained in step B to the mixture obtained in step A, control the stirring speed to 120-300r / min, and carry out the polymerization reaction at 70-95°C for 6 hours to obtain dispersions with different particle sizes;

[0064] D. Stir the dispersions of different particle sizes obtained in step C to room temperature to obtain the resin microsphere plugging agent.

Embodiment 1

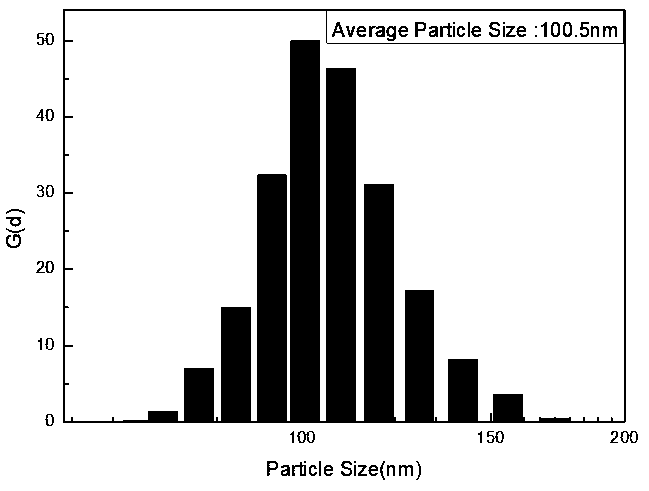

[0066]The preparation method of the resin microsphere blocking agent of this embodiment is: add 1 part of polyvinyl alcohol 1788 and 0.5 part of sodium hexametaphosphate into 80 parts of deionized water, stir at a speed of 120 r / min, heat up, and control the temperature to 60 ° C , and stirred for 1 h to obtain solution A. Add 0.6 parts of initiator azobisisobutyronitrile into a mixture containing 40 parts of styrene, 5 parts of glycidyl methacrylate and 5 parts of methyl methacrylate and 5 parts of diallyl phthalate to make the initiator The agent dissolves. The mixture of various monomers was added to the solution A, the stirring speed was controlled at 300r / min, and the temperature was 70°C to carry out the polymerization reaction for 6h. The obtained emulsion was cooled down to room temperature by stirring to obtain a dispersion of resin microspheres with a particle size of 200 μm.

Embodiment 2

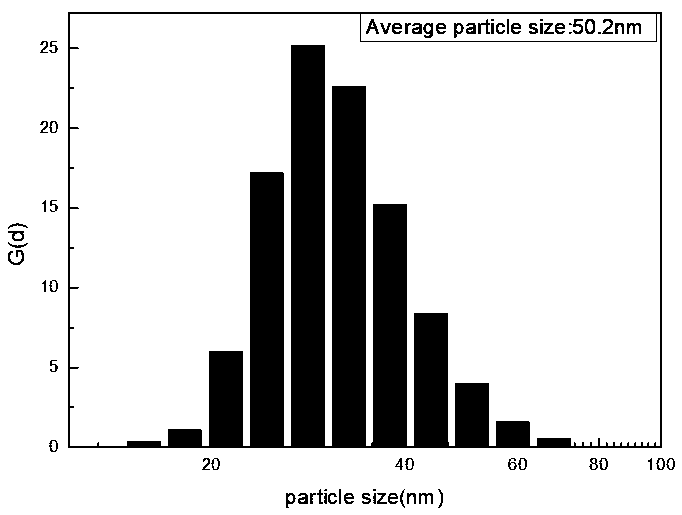

[0068] The preparation method of the resin microsphere plugging agent of this embodiment is: add 0.5 parts of polyethylene glycol 400 and 0.3 parts of sodium pyrophosphate to 90 parts of deionized water, stir at a speed of 120 r / min, heat up, and control the temperature to 60 ° C , and stirred for 1 h to obtain solution A. 0.7 parts of initiator azobisisobutyronitrile was added to a mixture containing 30 parts of styrene, 6 parts of butyl acrylate and 10 parts of diallyl phthalate to dissolve the initiator. The mixture of various monomers was added to the solution A, the stirring speed was controlled at 280r / min, and the temperature was 80°C to carry out the polymerization reaction for 6h. The obtained emulsion was cooled down to room temperature by stirring to obtain a microsphere dispersion with a particle size of 50 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com