Preparation method for salinity gradient power generation membrane hybridized by segmented copolymer membrane and functionality pore membrane

A block copolymer and functional technology, applied in the field of preparation of salt difference power generation membrane, can solve the problems of low energy density, short effective functional area, irregular pore structure, etc., to overcome the complexity of the preparation process and reduce the effective distance, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

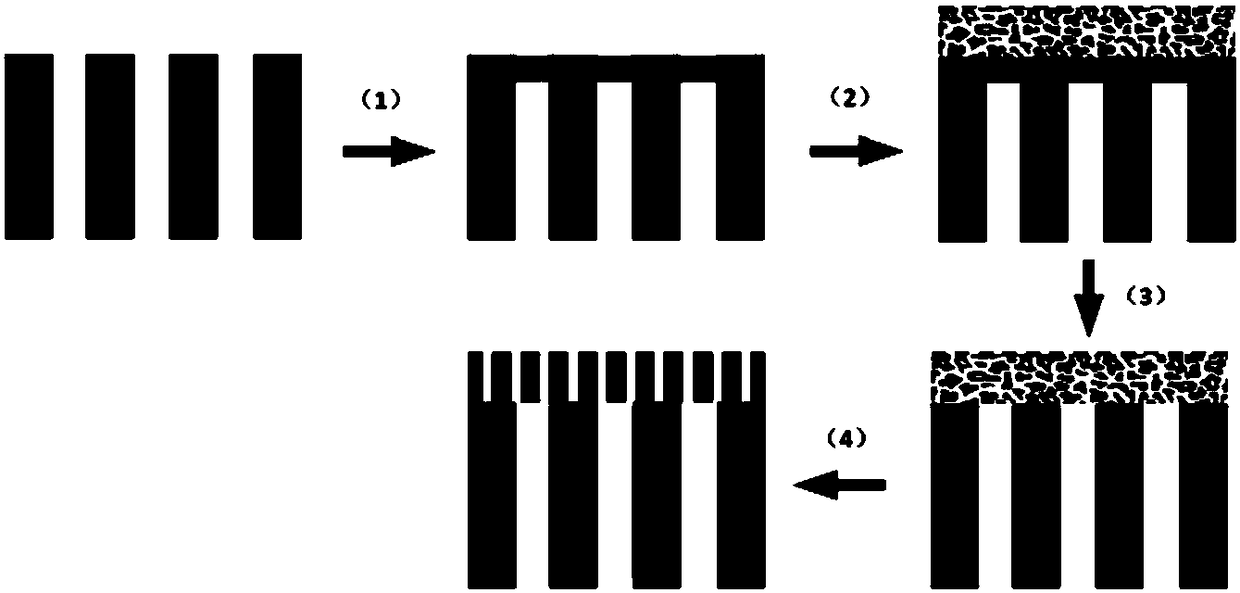

[0028] (1) Preparation of functional porous membrane substrates.

[0029] A porous alumina substrate with a channel diameter of 80 nm was prepared by anodic oxidation. The number of pores in the prepared porous membrane is 10 9 cm -2 , with a regular pore size distribution.

[0030] (2) Pretreatment of macroporous substrates.

[0031] Cellulose acetate is used as the plugging material, and the porous membrane in step (1) is treated with a sacrificial layer method to prevent solution leakage. First, an acetone solution of cellulose acetate with a mass fraction of 7% was prepared, and hang-coated (1000 r, 60 s) on the porous alumina substrate. The cellulose acetate on the surface was then wiped off with a cotton swab dipped in acetone, exposing a relatively smooth surface.

[0032] (3) Dissolution and film formation of block copolymers in selective solvents.

[0033] Select dichloromethane as the solvent to dissolve the block copolymer (poly(styrene-tetravinylpyridine)) wi...

Embodiment 2

[0041] (1) Preparation of functional porous membrane substrates.

[0042] A porous alumina substrate with a channel diameter of 40 nm was prepared by anodic oxidation. The number of pores in the prepared porous membrane is 10 9 cm -2 , with a regular pore size distribution.

[0043] (2) Pretreatment of macroporous substrates.

[0044] Cellulose acetate is used as the plugging material, and the porous membrane in step (1) is treated with a sacrificial layer method to prevent solution leakage. First, an acetone solution of cellulose acetate with a mass fraction of 7% was prepared, and hang-coated (1000 r, 60 s) on the porous alumina substrate. The cellulose acetate on the surface was then wiped off with a cotton swab dipped in acetone, exposing a relatively smooth surface.

[0045] (3) Dissolution and film formation of block copolymers in selective solvents.

[0046] Select dichloromethane as the solvent to dissolve the block copolymer (poly(styrene-tetravinylpyridine)) wi...

Embodiment 3

[0051] (1) Preparation of functional porous membrane substrates.

[0052] A porous alumina substrate with a channel diameter of 80 nm was prepared by anodic oxidation. The number of pores in the prepared porous membrane is 10 9 cm -2 , with a regular pore size distribution.

[0053] (2) Pretreatment of macroporous substrates.

[0054] Cellulose acetate is used as the plugging material, and the porous membrane in step (1) is treated with a sacrificial layer method to prevent solution leakage. First, an acetone solution of cellulose acetate with a mass fraction of 7% was prepared, and hang-coated (1000 r, 60 s) on the porous alumina substrate. The cellulose acetate on the surface was then wiped off with a cotton swab dipped in acetone, exposing a relatively smooth surface.

[0055] (3) Dissolution and film formation of block copolymers in selective solvents.

[0056] Select dichloromethane as the solvent to dissolve the block copolymer (poly(styrene-tetravinylpyridine)) wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com