Spray type transparent paper water-proofing agent

A waterproofing agent and paper technology, applied in the direction of water-repellent addition, papermaking, paper coating, etc., can solve the problems that affect the quality and appearance of woven handicrafts or daily necessities, it is difficult to firmly bond paper, and can not play a waterproof function, etc., to achieve Improve transparency and stability, improve fast bonding ability, improve decoration and use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

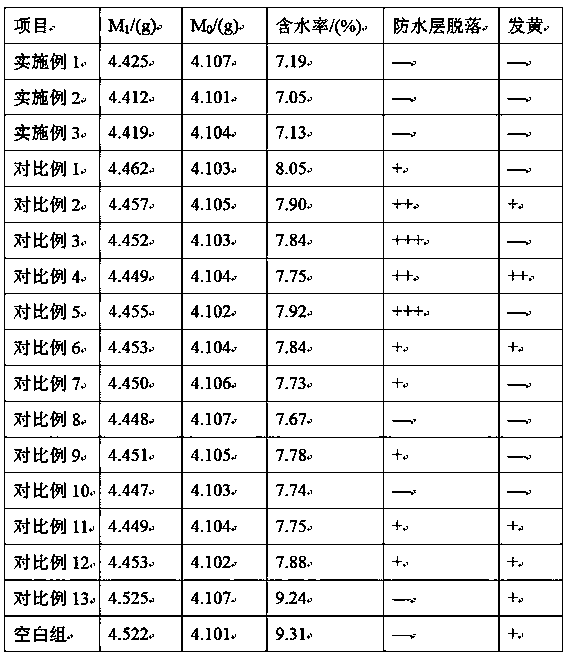

Examples

Embodiment 1

[0020] A spray-type transparent paper waterproofing agent, made of the following raw materials in parts by weight: natural resin 57, modified high-density polyethylene 31, sodium silicate 26, sodium selenite 10, nanofiber 6, phytic acid 5, poly Ethylene glycol 24.

[0021] For the modified high-density polyethylene, put the high-density polyethylene in a reaction kettle, heat it to 135°C at a rate of 1.5°C / min, keep it warm and stir for 20 minutes, add the allantoin solution, mix evenly, add the high-density polyethylene Nano-nickel with 0.02% ethylene weight, heat preservation and stirring for 60 minutes, add methyl silicone oil while stirring, naturally cool down to 110°C, heat preservation and stirring at 50 rpm for 30 minutes, so that the modified high-density polyethylene becomes a transparent liquid, which is convenient Use spray to form a protective film on the surface of the woven fabric to prevent the woven fabric from absorbing external moisture and obtain modified h...

Embodiment 2

[0031] A spray-type transparent paper waterproofing agent, made of the following raw materials in parts by weight: natural resin 58, modified high-density polyethylene 32, sodium silicate 27, sodium selenite 11, nanofiber 7, phytic acid 6, poly Ethylene glycol 25.

[0032]For the modified high-density polyethylene, put the high-density polyethylene in a reaction kettle, heat it to 140°C at a rate of 1.6°C / min, keep it warm and stir for 25 minutes, add the allantoin solution, mix evenly, add the high-density polyethylene Nano-nickel with 0.03% ethylene weight, heat preservation and stirring for 70 minutes, add methyl silicone oil while stirring, naturally cool down to 115°C, 53 rpm heat preservation and stirring for 35 minutes, so that the modified high-density polyethylene becomes a transparent liquid, which is convenient Use spray to form a protective film on the surface of the woven fabric to prevent the woven fabric from absorbing external moisture and obtain modified high-...

Embodiment 3

[0042] A spray-type transparent paper waterproofing agent, made of the following raw materials in parts by weight: natural resin 59, modified high-density polyethylene 33, sodium silicate 28, sodium selenite 12, nanofiber 8, phytic acid 7, poly Ethylene glycol 26.

[0043] For the modified high-density polyethylene, put the high-density polyethylene in a reaction kettle, heat it to 145°C at a rate of 1.7°C / min, keep it warm and stir for 30 minutes, add the allantoin solution, mix evenly, add the high-density polyethylene Nano-nickel with 0.04% ethylene weight, heat preservation and stirring for 90 minutes, add methyl silicone oil while stirring, naturally cool down to 120 ° C, 55 rpm heat preservation and stirring for 40 minutes, so that the modified high-density polyethylene becomes a transparent liquid, which is convenient Use spray to form a protective film on the surface of the woven fabric to prevent the woven fabric from absorbing external moisture and obtain modified hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com