Method for improving efficiency of waterborne polyurethane in synthetic leather production

A technology of water-based polyurethane and synthetic leather, which is applied in the direction of textiles and papermaking to achieve the effects of reducing production costs, optimizing performance, and shortening film-forming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

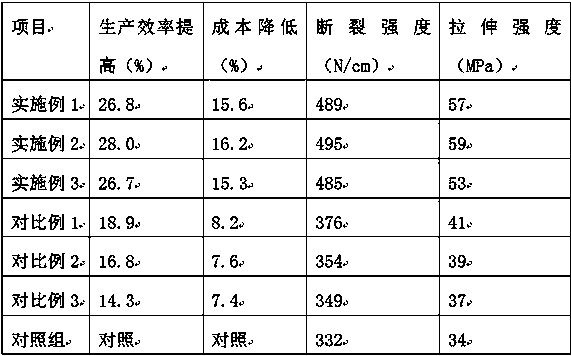

Examples

Embodiment 1

[0019] A method for improving the efficiency of water-based polyurethane in the production of synthetic leather, adding the following mass fractions of raw materials to the water-based polyurethane dispersion: 2.5% organometallic sol, 0.4% thickener, 0.20% defoamer, 0.12% Leveling agent, 0.05% white carbon black, stirred and mixed at 700 rpm for 10 minutes, the prepared emulsion slurry was passed through a 120-mesh filter screen, and water-based polyurethane synthetic leather was prepared by conventional dry film transfer method;

[0020] The preparation method of the organometallic sol is as follows: add 15 grams of antimony pentoxide powder, 80 milliliters of tetrahydrofuran, and 1.2 grams of sodium hydroxide to a three-necked flask, stir well, slowly add 15 milliliters of acetone, and heat to reflux for 4 hours , the heating temperature is 65°C, after the reaction is completed, use hydrochloric acid to dissolve and neutralize until the pH value is in the range of 6.8-7.0, an...

Embodiment 2

[0030] A method for improving the efficiency of water-based polyurethane in the production of synthetic leather, adding the following mass fractions of raw materials to the water-based polyurethane dispersion: 2.6% organometallic sol, 0.45% thickener, 0.23% defoamer, 0.13% Leveling agent, 0.06% white carbon black, stirred and mixed for 13 minutes at 750 rpm, the prepared emulsion slurry was passed through a 130-mesh filter screen, and the water-based polyurethane synthetic leather was prepared by a conventional dry method transfer film method;

[0031] The preparation method of the organometallic sol is as follows: add 15.5 grams of antimony pentoxide powder, 82 milliliters of tetrahydrofuran, and 1.3 grams of sodium hydroxide into a three-necked flask, stir evenly, slowly add 18 milliliters of acetone, and heat to reflux for 4.5 hours , the heating temperature is 68°C, after the reaction is completed, use hydrochloric acid to dissolve and neutralize until the pH value is in th...

Embodiment 3

[0041] A method for improving the efficiency of water-based polyurethane in the production of synthetic leather, adding the following mass fractions of raw materials to the water-based polyurethane dispersion: 2.7% organometallic sol, 0.5% thickener, 0.25% defoamer, 0.14% Leveling agent, 0.08% white carbon black, stirred and mixed at 800 rpm for 15 minutes, the prepared emulsion slurry was passed through a 150-mesh filter, and water-based polyurethane synthetic leather was prepared by conventional dry method transfer film method;

[0042] The preparation method of the organometallic sol is as follows: add 16 grams of antimony pentoxide powder, 85 milliliters of tetrahydrofuran, and 1.5 grams of sodium hydroxide into a three-necked flask, stir well, slowly add 20 milliliters of acetone dropwise, and heat to reflux for 5 hours , the heating temperature is 70°C, after the reaction is completed, use hydrochloric acid to dissolve and neutralize until the pH value is in the range of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com