Method for recycling cadmium metal from dust of lead-smelting bottom-blowing furnace

A bottom-blowing furnace and lead smelting technology is applied in the field of soot and cadmium metal recovery of lead smelting bottom-blowing furnaces, which can solve problems such as affecting the normal production of oxygen bottom-blowing furnaces, and achieve the effects of feasible process, simple process and high leaching rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

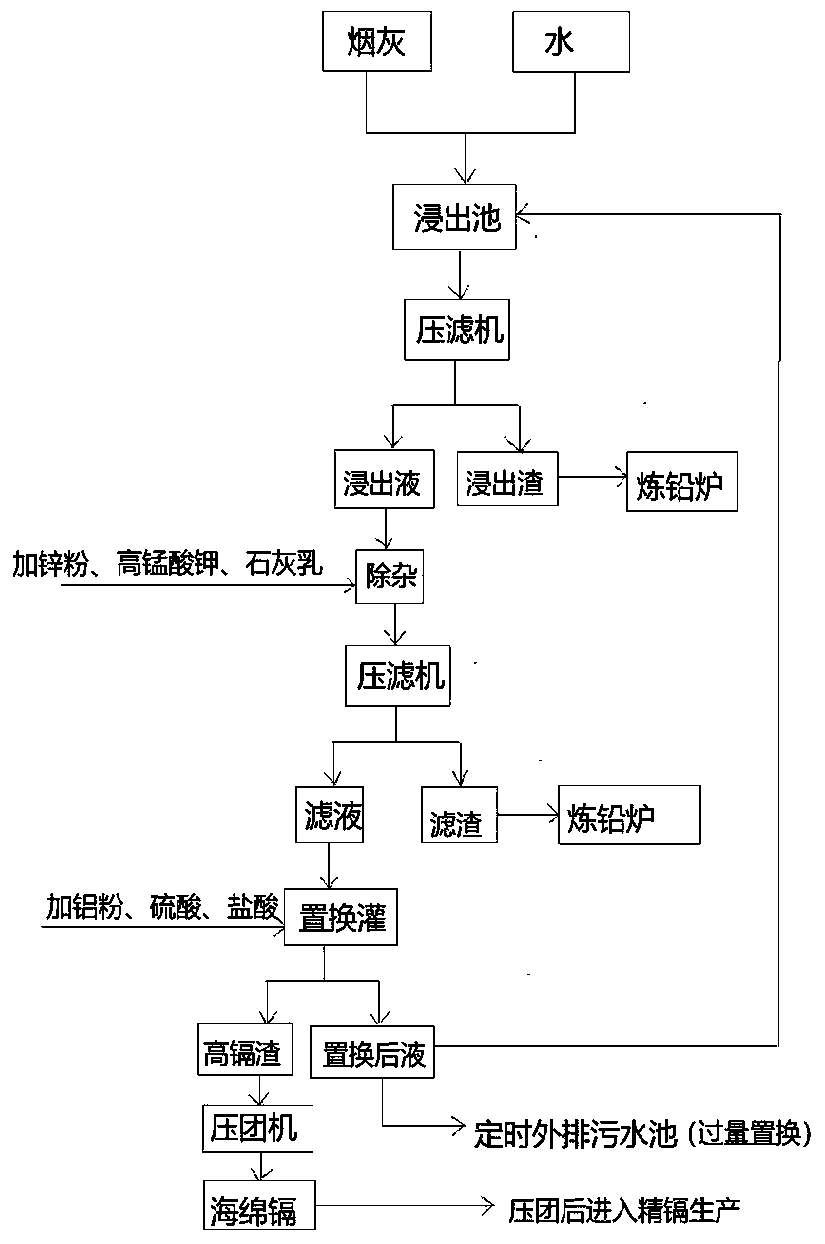

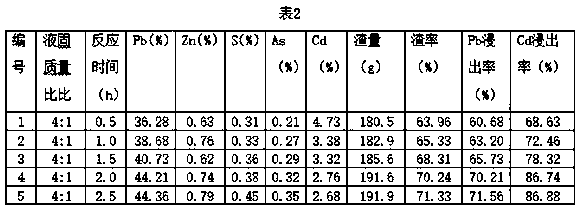

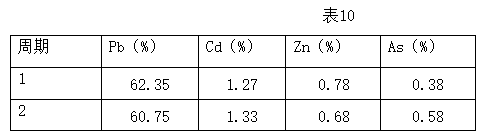

[0019] A method for recovering cadmium metal from lead smelting bottom-blown furnace soot, comprising the following steps, (1) leaching process: take lead smelting bottom-blown furnace soot and carry out water leaching, so that Cd compounds enter the liquid phase, and compounds such as Pb and As are insoluble in The water is enriched in the leaching slag; then separated to obtain the leaching liquid and leaching slag; the leaching slag can be sent to the lead smelting furnace.

[0020] (2) Replacement process: Take the leaching solution, adjust the pH to 2.0-2.5 with a mixture of sulfuric acid and hydrochloric acid, heat to 103-105°C, and replace it with aluminum powder with a particle size of 140-200 mesh to obtain high-cadmium slag and replaced liquid; pH adjustment can be adjusted with industrial grade hydrochloric acid and sulfuric acid. High cadmium slag can be pressed into sponge cadmium through a compactor, and then enter the production of refined cadmium.

[0021] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com