Preparation method and application of biomass briquette binder

A technology of binder and biomass, which is applied in the field of preparation of biomass briquette binder to achieve the effect of reducing pollution, good bonding and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

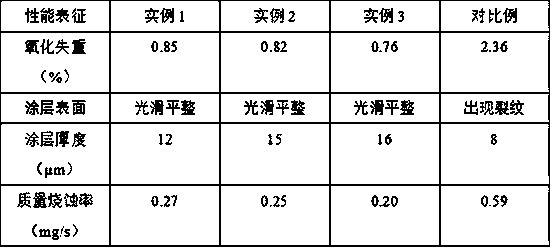

Examples

example 1

[0024] Take 200g of molasses and add it into 300mL of deionized water, stir at 300r / min for 20min, then add 30g of quicklime, and continue stirring for 30min to obtain a mixed solution, dry the corn stalks naturally, put them into a pulverizer and grind them, pass through a 200-mesh sieve, and take 300g to pass through a sieve. The sieved corn stalk powder was added to the mixture, and the pH was adjusted to 11 with 5% sodium hydroxide, then stirred and reacted at 200r / min at 60°C for 2 hours, and 90g of 5% was added after cooling to room temperature The polyvinyl alcohol solution was stirred at 1800r / min for 20min to obtain a biomass briquette binder. The coal powder was put into a pulverizer and pulverized, then transferred to a sieve machine and screened through a standard sieve to select 0-0.5mm, 0.5 ~1mm, 1~2mm, 2~3mm particle size coal powder, and according to 0~0.5mm particle size 60%, 0.5~1mm particle size 10%, 1~2mm particle size 18%, 2~3mm particle size 12% Perform b...

example 2

[0026] Add 250g of molasses into 350mL of deionized water, stir at 350r / min for 25min, then add 35g of quicklime, and continue stirring for 35min to obtain a mixed solution, dry the corn stalks naturally, put them into a pulverizer and grind them, pass through a 200-mesh sieve, and take 400g to pass through a sieve. The sieved corn stalk powder was added to the mixture, and the pH was adjusted to 11 with 5% sodium hydroxide, then stirred and reacted at 250r / min at 70°C for 2 hours, and 95g was added after cooling to room temperature with a mass fraction of 5% The polyvinyl alcohol solution was stirred at 2000r / min for 25min to obtain the biomass briquette binder, the pulverized coal was put into a pulverizer and pulverized, then transferred to a sieve machine and passed through a standard sieve to select 0-0.5mm, 0.5 ~1mm, 1~2mm, 2~3mm particle size coal powder, and according to 0~0.5mm particle size 55%, 0.5~1mm particle size 11%, 1~2mm particle size 19%, 2~3mm particle size 1...

example 3

[0028] Take 300g of molasses and add it to 400mL of deionized water, stir at 400r / min for 30min, then add 40g of quicklime, and continue stirring for 40min to obtain a mixed solution, dry the corn stalks naturally, put them into a pulverizer and grind them, pass through a 200-mesh sieve, and take 500g to pass through a sieve. The sieved corn stalk powder was added to the mixture, and the pH was adjusted to 12 with 5% sodium hydroxide, then stirred and reacted at 300r / min at 80°C for 3 hours, and 100g was added after cooling to room temperature with a mass fraction of 5% The polyvinyl alcohol solution was stirred at 2400r / min for 30min to obtain the biomass briquette binder, the pulverized coal was put into a pulverizer and pulverized, then transferred to a sieve machine and passed through a standard sieve to select 0-0.5mm, 0.5 ~1mm, 1~2mm, 2~3mm particle size coal powder, and according to 0~0.5mm particle size 50%, 0.5~1mm particle size 15%, 1~2mm particle size 20%, 2~3mm part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com