High-hardness alkali-free aluminoborosilicate glass suitable for float process production, and preparation method and application of aluminoborosilicate glass

A technology of borosilicate glass and float process, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc. It can solve the problems of difficult glass melting, poor homogenization effect, and deterioration of film characteristics, so as to improve the hardness of glass , shorten the material properties, reduce the high temperature viscosity and the effect of melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

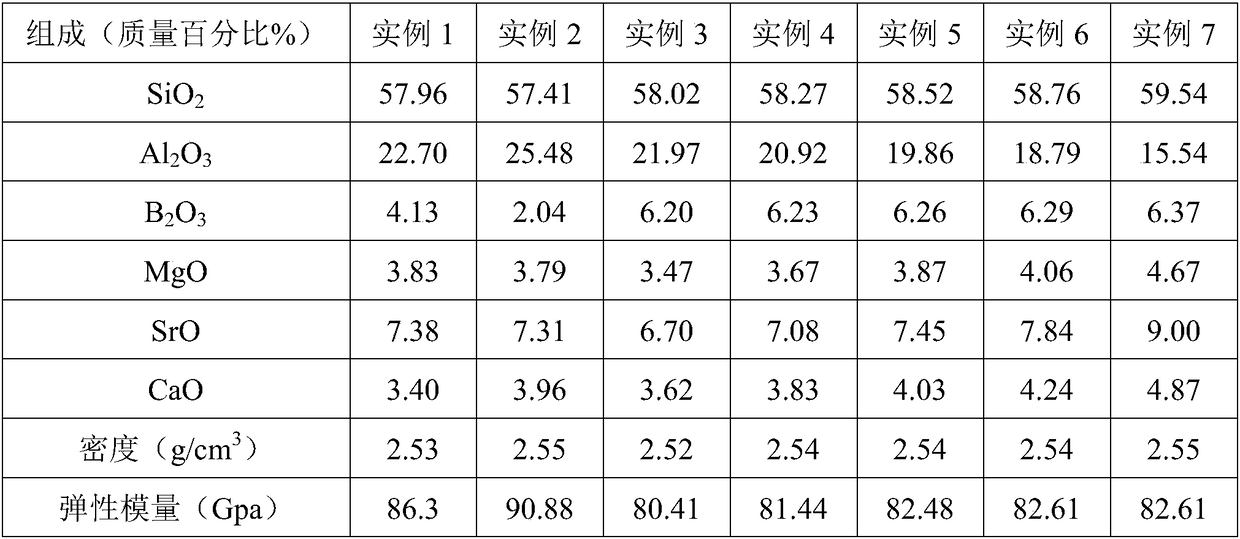

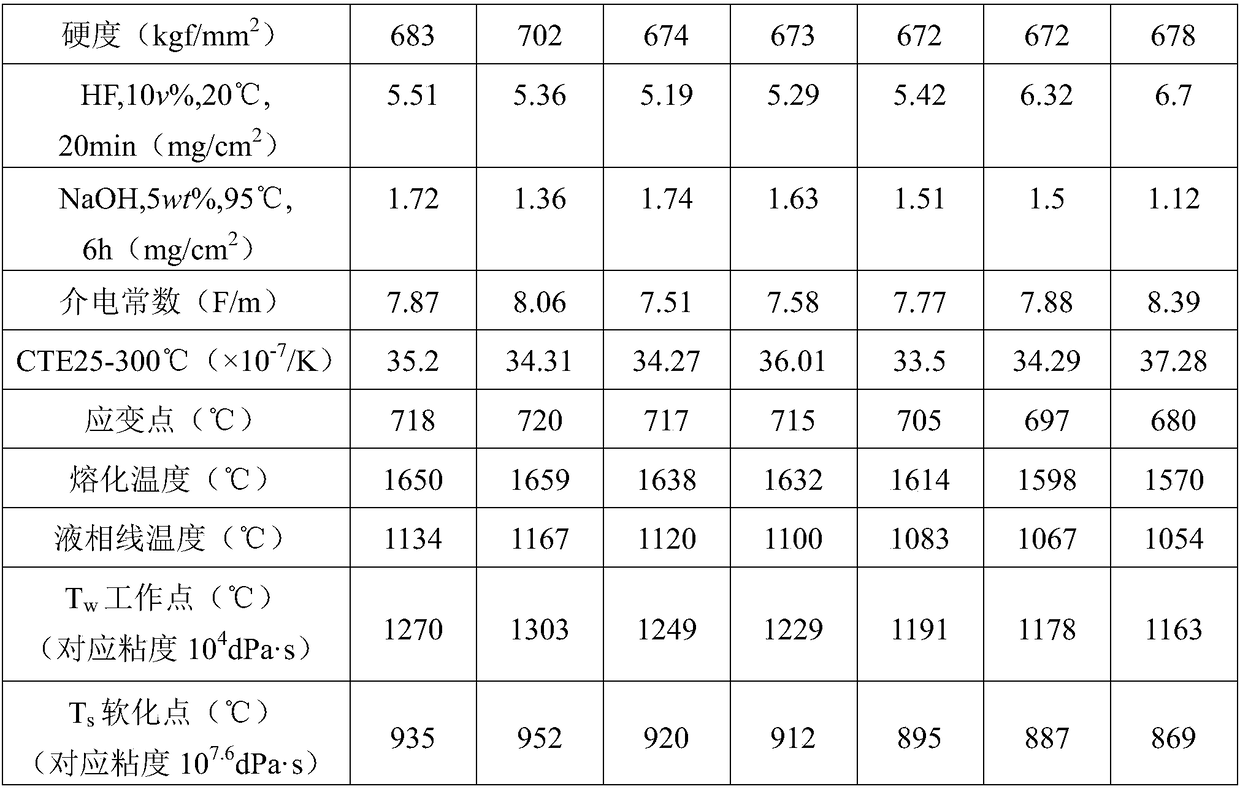

Examples

preparation example Construction

[0032] The preparation method of a kind of high hardness alkali-free aluminoborosilicate glass provided by the present invention, the steps are as follows:

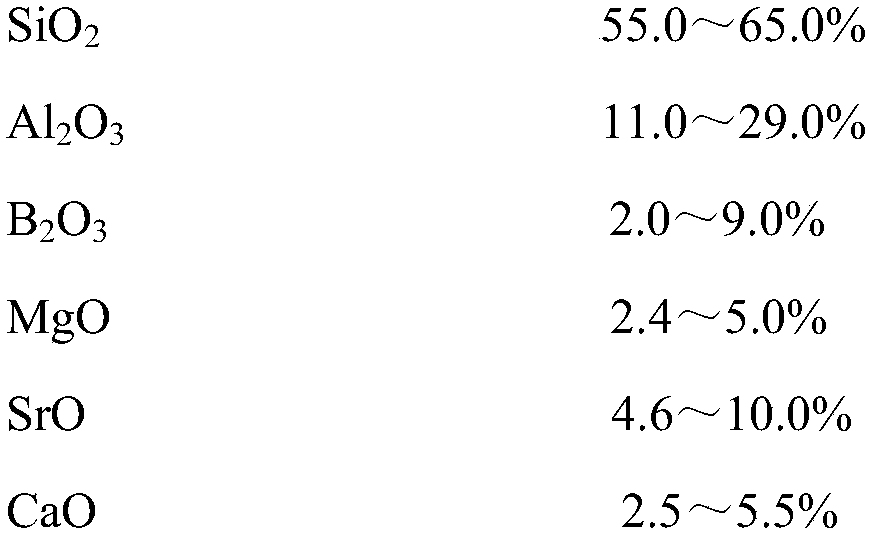

[0033] 1) Selection of raw materials: according to SiO 2 55.0~65.0%, Al 2 o 3 11.0-29.0%, B 2 o 3 2.0~9.0%, MgO 2.4~5.0%, SrO 4.6~10.0%, CaO 2.5~5.5% ingredients, in terms of mass percentage, the sum of each oxide satisfies 100%, of which SiO 2 、Al 2 o 3 , B 2 o 3 , MgO, CaO, and SrO are respectively introduced from quartz sand, alumina, boric acid, light magnesium oxide, calcium carbonate, and strontium carbonate;

[0034] 2) Calculate the mass fraction of the batch according to the mass fraction of the above-mentioned oxides and weigh about 200g of the batch. After mixing evenly, add it to a platinum-rhodium alloy crucible and melt it, keep it warm at 1620-1660°C for 2-3 hours, and then melt the prepared The molten glass is poured into a stainless steel cast iron mold preheated to 200-300°C for rapid prototy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com