Production method of highly stable and biodegradable double-network oil-water separation net membrane

A technology of oil-water separation omentum and biodegradation, which is applied in the field of preparation of oil-water separation materials, can solve the problems of the hydrophilic layer substrate falling off or being damaged, the omentum material is not easy to biodegrade, and the efficiency of oil-water separation decreases, etc., to achieve good superoleophobicity capacity, high oil/water separation efficiency, and fast filtration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

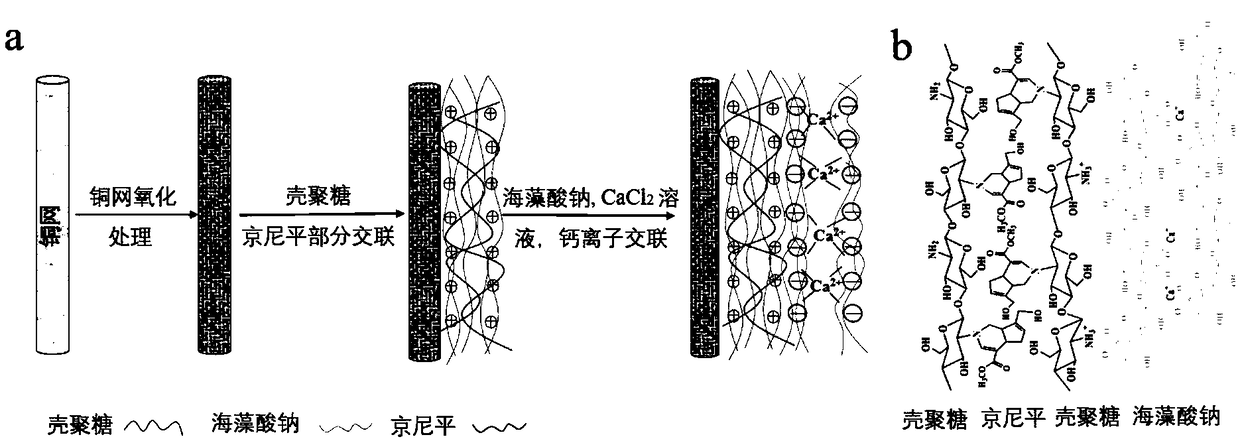

[0055] A kind of preparation method with high stability biodegradable double network oil-water separation omentum, comprises the following steps (as Figure 1-4 shown):

[0056] 1. Preparation of copper mesh with nano-sheet rough structure on the surface:

[0057] (1) Get a copper mesh with a diameter of 3 cm and an average aperture of 30 microns (such as figure 2 a and figure 2 As shown in b), soak the copper mesh in ethanol or acetone, place it in an ultrasonic device for 20-30 minutes, take out the copper mesh and rinse it with deionized water for 3-5 times, and then place it in ultrasonic water for 6-15 minutes;

[0058] (2) Place the cleaned copper grid in a mixed solution of 0.2mol / L sodium hydroxide and 0.1mol / L ammonium persulfate, soak for 0.5-2h;

[0059] (3) Take out the copper mesh, clean it with ultrapure water, and purge the surface of the copper mesh with nitrogen until dry, and obtain a copper mesh with a nano-sheet rough structure on the surface (such as ...

Embodiment 2

[0074] A kind of preparation method with high stability biodegradable double network oil-water separation omentum, comprises the following steps:

[0075] 1. Preparation of copper mesh with nano-sheet rough structure on the surface:

[0076] (1) Take a copper mesh with a diameter of 5 cm and an average pore size of 40 microns, soak the copper mesh in ethanol or acetone, place it in an ultrasonic device for 20-30 minutes, take out the copper mesh and rinse it with deionized water for 3- 5 times, and then washed in ultrasonic water for 6-15 minutes;

[0077] (2) Place the cleaned copper grid in a mixed solution of 0.4mol / L sodium hydroxide and 0.3mol / L ammonium persulfate, soak for 0.5-2h;

[0078] (3) Take out the copper mesh, clean it with ultrapure water, and purge the surface of the copper mesh with nitrogen until dry to obtain a copper mesh with a nano-sheet rough structure on the surface;

[0079] (1) A certain amount of chitosan is dissolved in 2wt% acetic acid aqueous ...

Embodiment 3

[0089] A kind of preparation method with high stability biodegradable double network oil-water separation omentum, comprises the following steps:

[0090] 1. Preparation of copper mesh with nano-sheet rough structure on the surface:

[0091] (1) Take a copper mesh with a diameter of 4 cm and an average pore size of 50 microns, soak the copper mesh in ethanol or acetone, place it in an ultrasonic device for 20-30 minutes, take out the copper mesh and rinse it with deionized water for 3- 5 times, and then washed in ultrasonic water for 6-15 minutes;

[0092] (2) Place the cleaned copper grid in a mixed solution of 6mol / L sodium hydroxide and 2mol / L ammonium persulfate, soak for 0.5-2h;

[0093] (3) Take out the copper mesh, clean it with ultrapure water, and purge the surface of the copper mesh with nitrogen until dry to obtain a copper mesh with a nano-sheet rough structure on the surface;

[0094] 2. Preparation of genipin partially cross-linked chitosan omentum:

[0095] (1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com