Anti-chicken heat stress premix and preparation method thereof

A heat stress and premix technology for chickens, applied in application, animal feed, animal feed, etc., can solve problems such as efficacy differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] First, the eucalyptus leaf extract and zeolite powder were pulverized, and 280 g of eucalyptus leaf extract, 190 g of zeolite powder, 160 g of potassium sulfate, 150 g of sodium bicarbonate, 130 g of magnesium sulfate, and 90 g of lysine were weighed respectively. Potassium sulfate, magnesium sulfate, and lysine are dissolved in 3.8L of water to form a trace element solution, and then the pulverized eucalyptus leaf extract and zeolite powder are poured into the above solution and fully stirred. The mixture was homogenized three times under the condition of a high-pressure homogenizer of 5Mpa to fully mix the sample, and the dry mixture sample was obtained under the conditions of spray drying at an air inlet temperature of 180°C and an air outlet temperature of 90°C. Finally, sodium bicarbonate was added to the dry mixture sample, and after thorough mixing, 1 kg of anti-chicken heat stress premix was obtained. Eucalyptus leaf extract is a hydroalcoholic extract obtained ...

Embodiment 2

[0023] First, the eucalyptus leaf extract and zeolite powder were pulverized, and 260 g of eucalyptus leaf extract, 210 g of zeolite powder, 160 g of potassium sulfate, 140 g of sodium bicarbonate, 150 g of magnesium sulfate, and 80 g of lysine were weighed respectively. Potassium sulfate, magnesium sulfate, and lysine are dissolved in 3.9L of water to form a trace element solution, and then the pulverized eucalyptus leaf extract and zeolite powder are poured into the above solution and fully stirred. The mixture was homogenized three times under the condition of a high-pressure homogenizer of 5Mpa to fully mix the sample, and the dry mixture sample was obtained under the conditions of spray drying at an air inlet temperature of 180°C and an air outlet temperature of 90°C. Finally, sodium bicarbonate was added to the dry mixture sample, and after thorough mixing, 1 kg of anti-chicken heat stress premix was obtained.

Embodiment 3

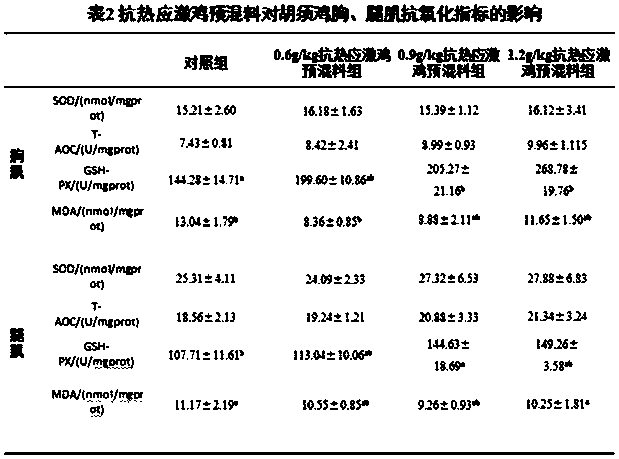

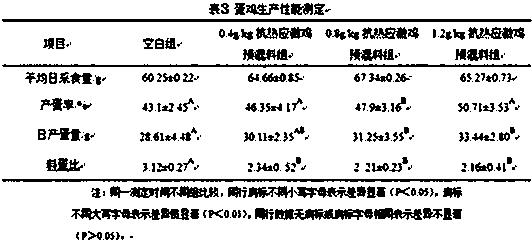

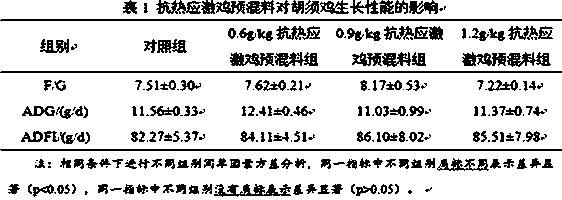

[0025] A total of 200 chickens with similar body weight and normal growth were selected and randomly divided into 4 treatment groups with 5 repetitions in each group. Group A is the control group, fed with normal basal feed; Group B, added 0.6g / kg anti-heat stress chicken premix to the basal feed; Group C, added 0.9g / kg anti-heat stress chicken premix to the basal diet Chicken premix; group D, add 1.2g / kg anti-heat stress chicken premix to the basal diet. During the feeding process, the animals were fed ad libitum, and the same feeding management was adopted. The experimental environment was 35°C±1°C, and the test period was 40 days. The index of investigation is mainly anti-oxidation index.

[0026]

[0027] The anti-heat stress chicken premix consists of 28% eucalyptus leaf extract, 19% zeolite powder, 16% potassium sulfate, 15% sodium bicarbonate, 13% magnesium sulfate, and 9% lysine.

[0028] The results showed (Table 1): the anti-heat stress chicken premix had no sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com