Method for desiliconizing silicon and aluminum containing material

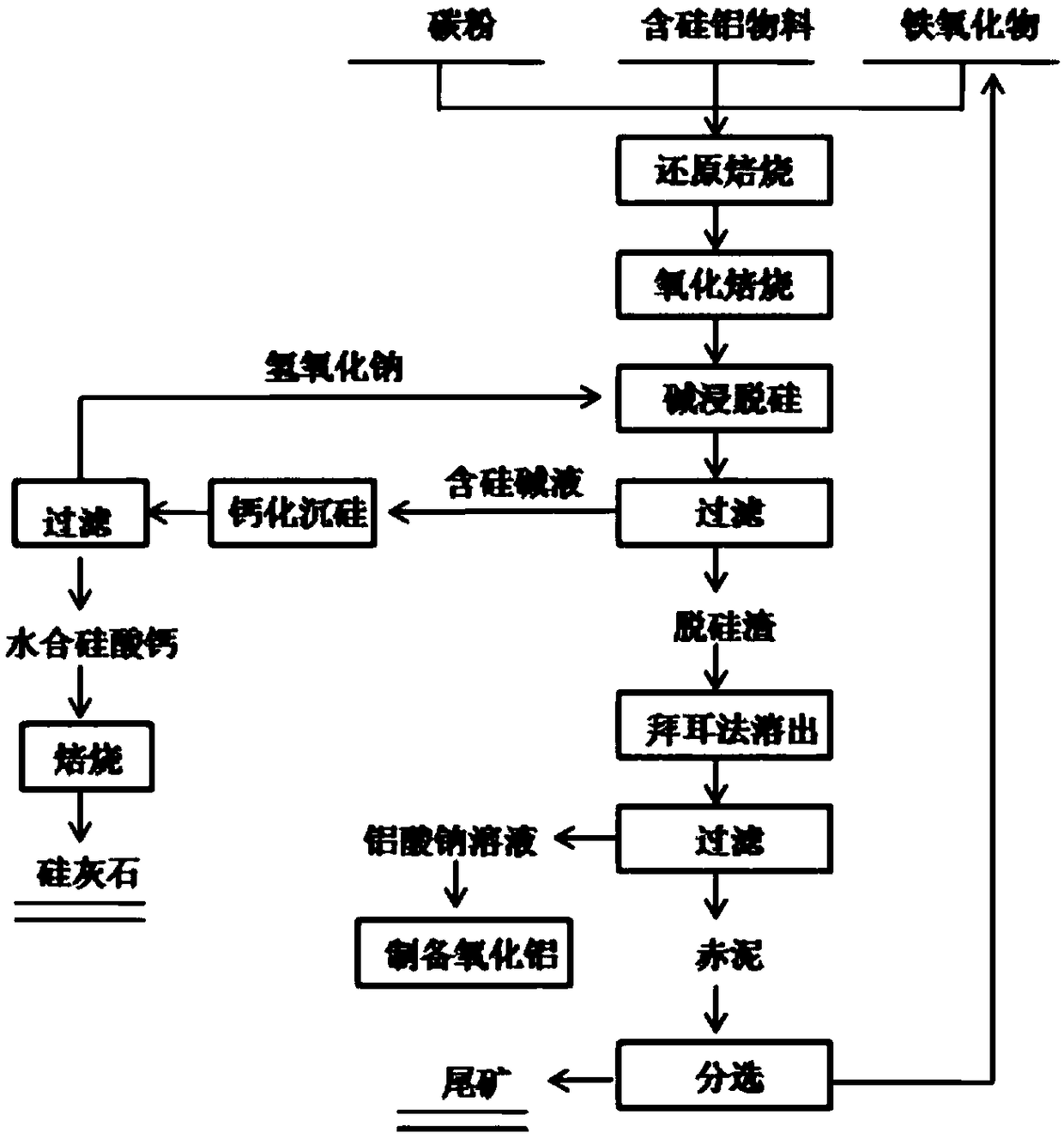

A material, silicon-aluminum technology, which is applied in the field of desiliconization of silicon-aluminum materials, can solve the problems of low silicon oxide dissolution rate and difficult desiliconization of high-silicon and aluminum-containing minerals, so as to increase the added value of products, improve the purity, and improve the economy. Significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

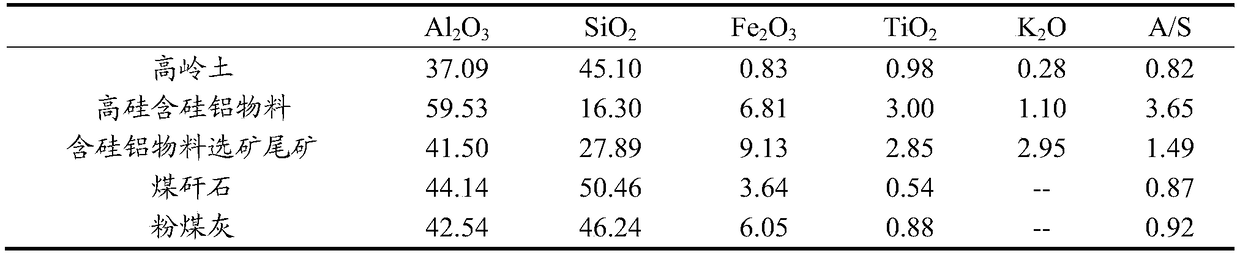

[0037] The molar ratio of iron oxide: alumina in kaolin: carbon = 1.1:2:1.1 is used for batching, and after roasting in a reducing atmosphere at 1100°C for 60 minutes, it is oxidized and roasted at 900°C for 30 minutes; the obtained roasted clinker is finely ground to less than 74μm , use sodium hydroxide solution to desilicate roasted clinker by alkali leaching, the leaching temperature is 110°C, the liquid-solid ratio is 5, the concentration of sodium hydroxide solution is 160g / L, and the leaching time is 120min. Under these conditions, the silicon oxide The dissolution rate was 90.5%.

[0038] Add digested calcium oxide to the silicon-containing alkali solution obtained by desiliconization according to the ratio of calcium-silicon molecular ratio of 1:1, hydrothermally react at 110°C for 5 hours, the silicon precipitation rate reaches 95.7%, and the sodium hydroxide obtained by separation The solution can be returned to the alkali leaching desiliconization process to contin...

Embodiment 2

[0041] The molar ratio of iron oxide: alumina in kaolin: carbon = 1.1:2:1.1 is used for batching, and after roasting in a reducing atmosphere at 1050°C for 60 minutes, it is oxidized and roasted at 950°C for 30 minutes; the obtained roasted clinker is finely ground to less than 74μm , use sodium hydroxide solution to desilicate roasted clinker by alkali leaching, the leaching temperature is 110°C, the liquid-solid ratio is 5, the concentration of sodium hydroxide solution is 160g / L, and the leaching time is 120min. Under these conditions, the silicon oxide The dissolution rate was 90.1%.

[0042] Add digested calcium oxide to the silicon-containing alkali solution obtained by desiliconization according to the ratio of calcium to silicon molecular ratio of 1:1, and react hydrothermally at 110°C for 5 hours, the silicon precipitation rate reaches 95.02%, and the sodium hydroxide obtained by separation The solution can be returned to the alkali leaching desiliconization process t...

Embodiment 3

[0045] The molar ratio of iron oxide: alumina in kaolin: carbon = 1.2:2:1.2 is used for batching, and after roasting in a reducing atmosphere at 1100°C for 60 minutes, it is oxidized and roasted at 1000°C for 30 minutes; the obtained roasted clinker is finely ground to less than 74μm , using sodium hydroxide solution to desilicate roasted clinker by alkali leaching, the leaching temperature is 110°C, the liquid-solid ratio is 3, the concentration of sodium hydroxide solution is 200g / L, and the leaching time is 120min. Under these conditions, the silicon oxide The dissolution rate was 89.87%.

[0046] Add digested calcium oxide to the silicon-containing alkali solution obtained by desiliconization according to the ratio of calcium to silicon molecular ratio of 1:1, hydrothermal reaction at 110°C for 5 hours, the silicon precipitation rate reaches 95.01%, and the sodium hydroxide obtained by separation The solution can be returned to the alkali leaching desiliconization process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com