Processing method for dry-jointed assembled partition boards

A processing method and assembly technology, applied in the direction of walls, manufacturing tools, building components, etc., can solve the problems of easy generation of waste water, dust, unenvironmental construction, low assembly efficiency, etc., and achieve good integrity, high construction efficiency, and construction. Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

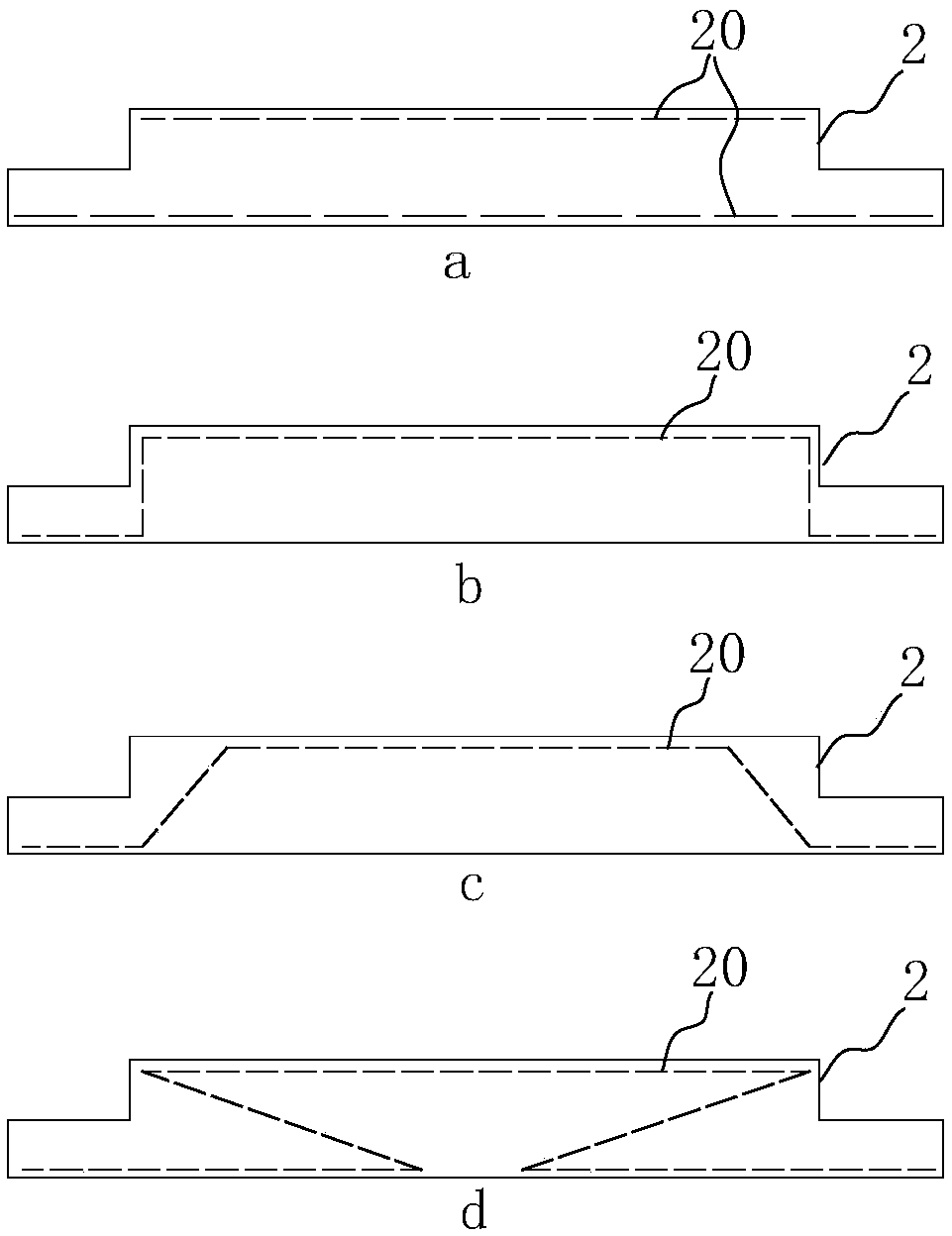

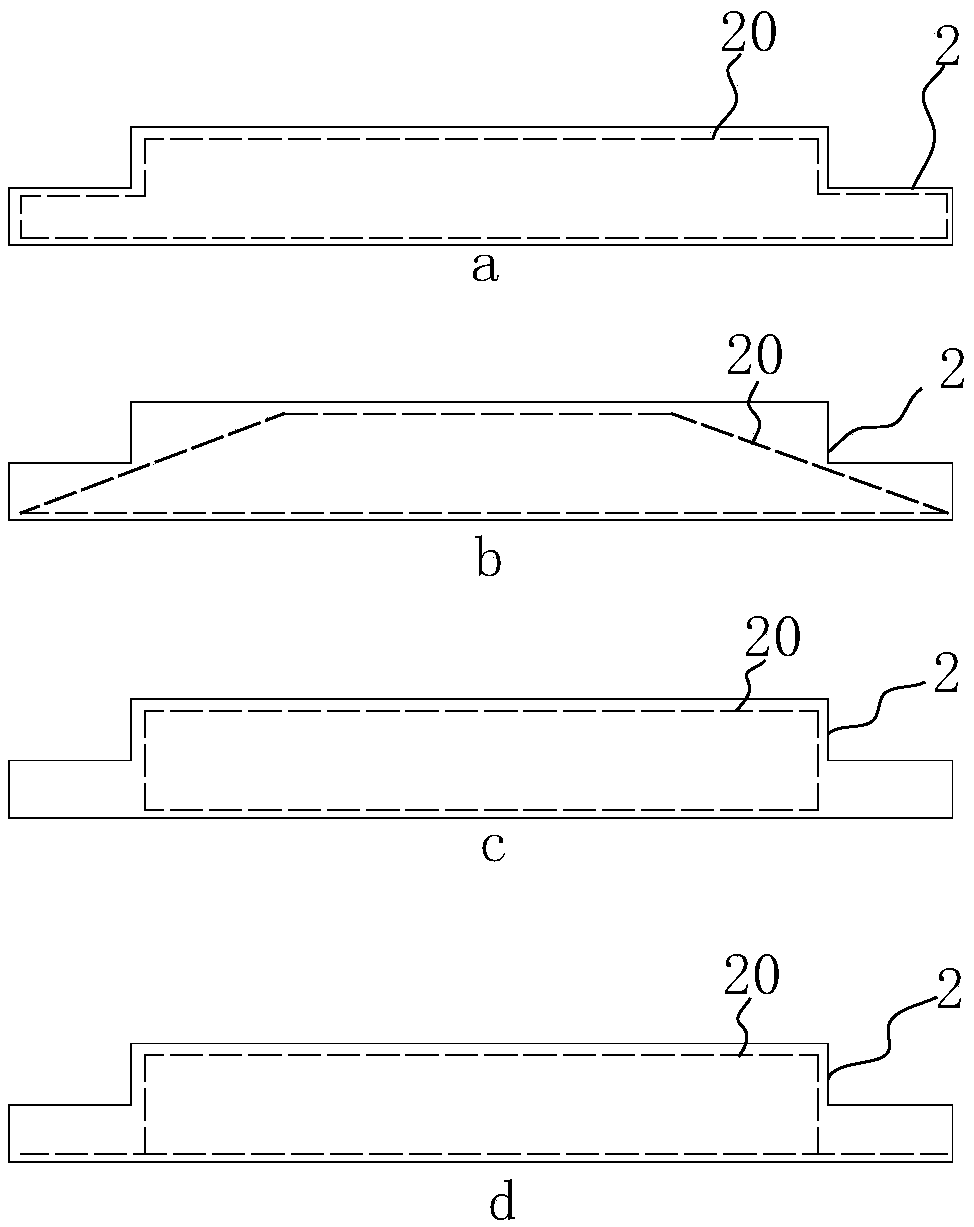

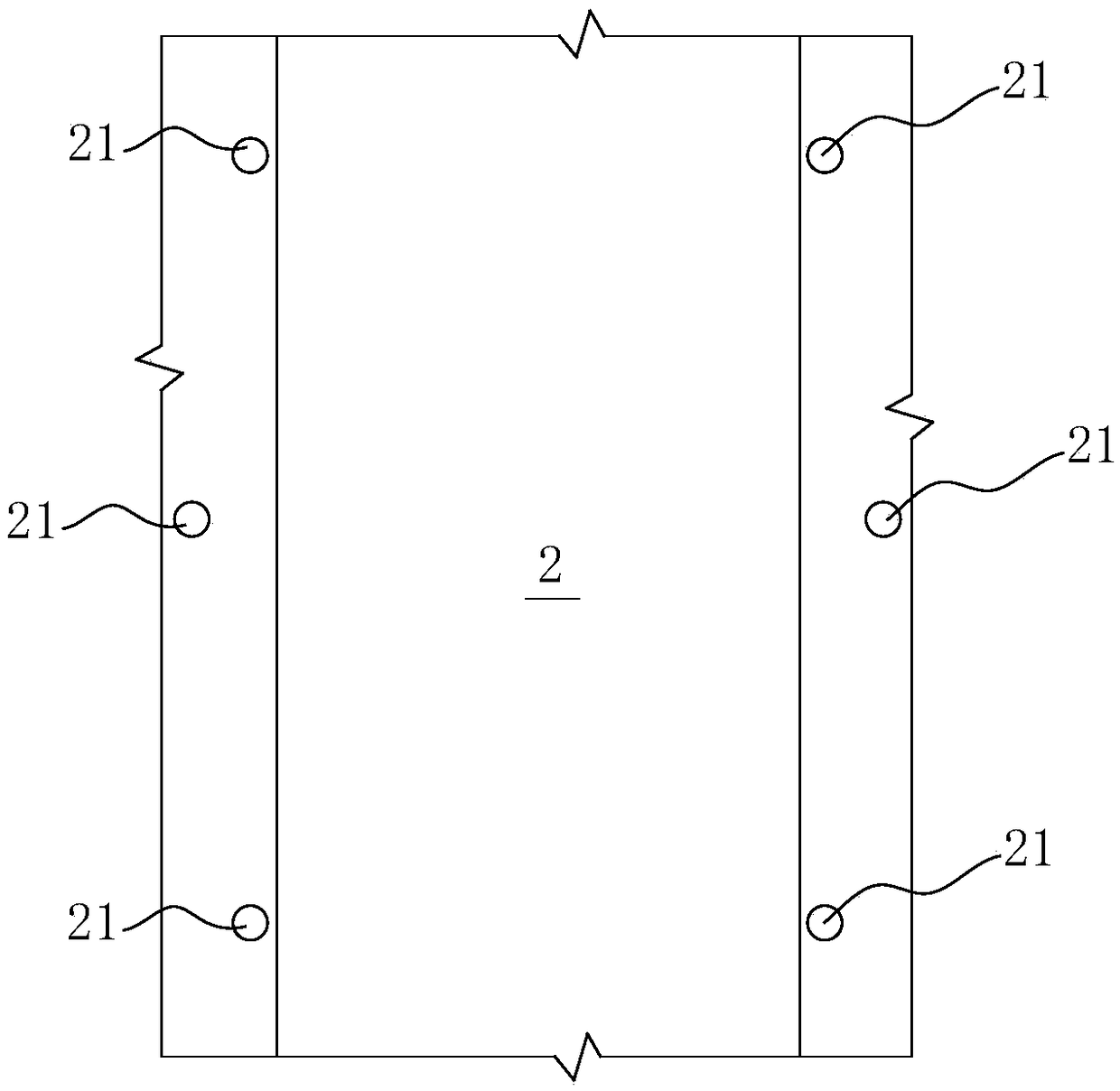

Method used

Image

Examples

preparation example Construction

[0040] The preparation step of described concrete comprises:

[0041] (1) In parts by weight, add 1 to 2 parts of tannic acid to 8 to 13 parts of saturated CaCl at 25°C 2 In the aqueous solution, after the precipitate is no longer precipitated in the solution, the precipitate is filtered and dried to obtain tannic acid chelating calcium ions.

[0042] (2) In parts by weight, 7 to 14 parts of tannins for chelating calcium ions are added to 16 to 25 parts of phenolic resins, 1 to 2 parts of basic catalysts are added, and the temperature is raised to 40° C. after stirring and mixing. Reaction 1h. Then add 34-50 parts of sulfoaluminate cement, 25-35 parts of fly ash, 1-2 parts of polycarboxylate superplasticizer, stir and mix well, add water and stir fully, so as to obtain quick-drying, high-strength , self-healing concrete; the total weight of each of the above components is 100 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com