Carbon nitride quantum dot-modified hierarchical-pore TiO2-SiO2 photocatalyst

A photocatalyst, quantum dot technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve high specific surface area, be beneficial to photocatalytic activity, and improve the effect of photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

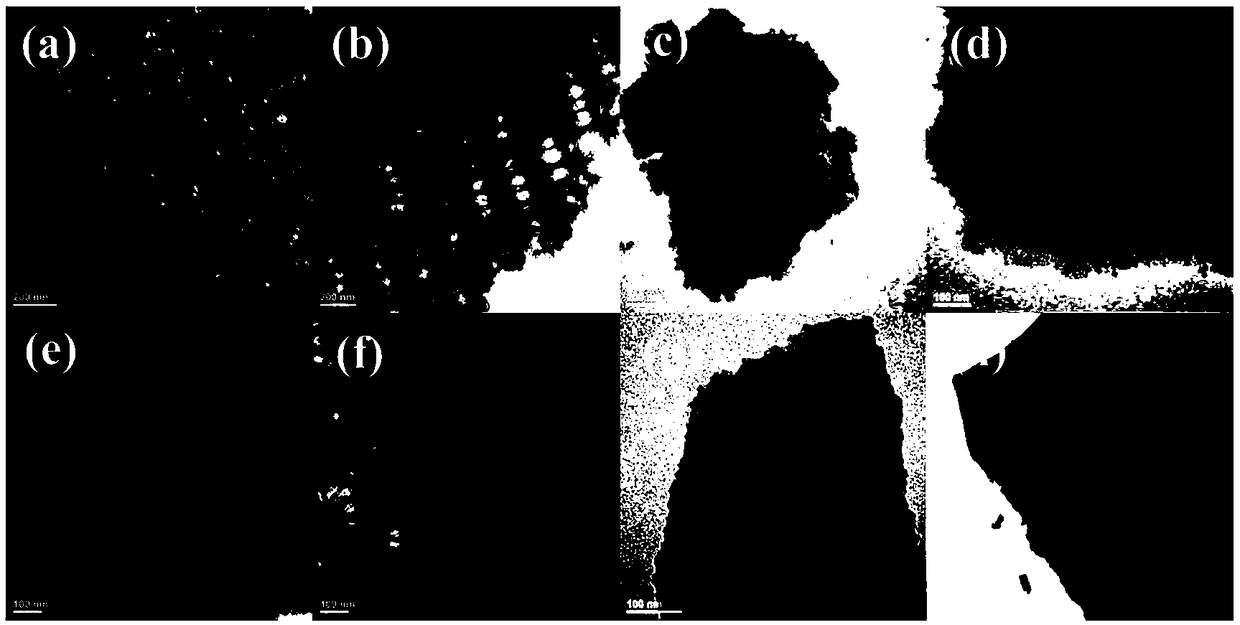

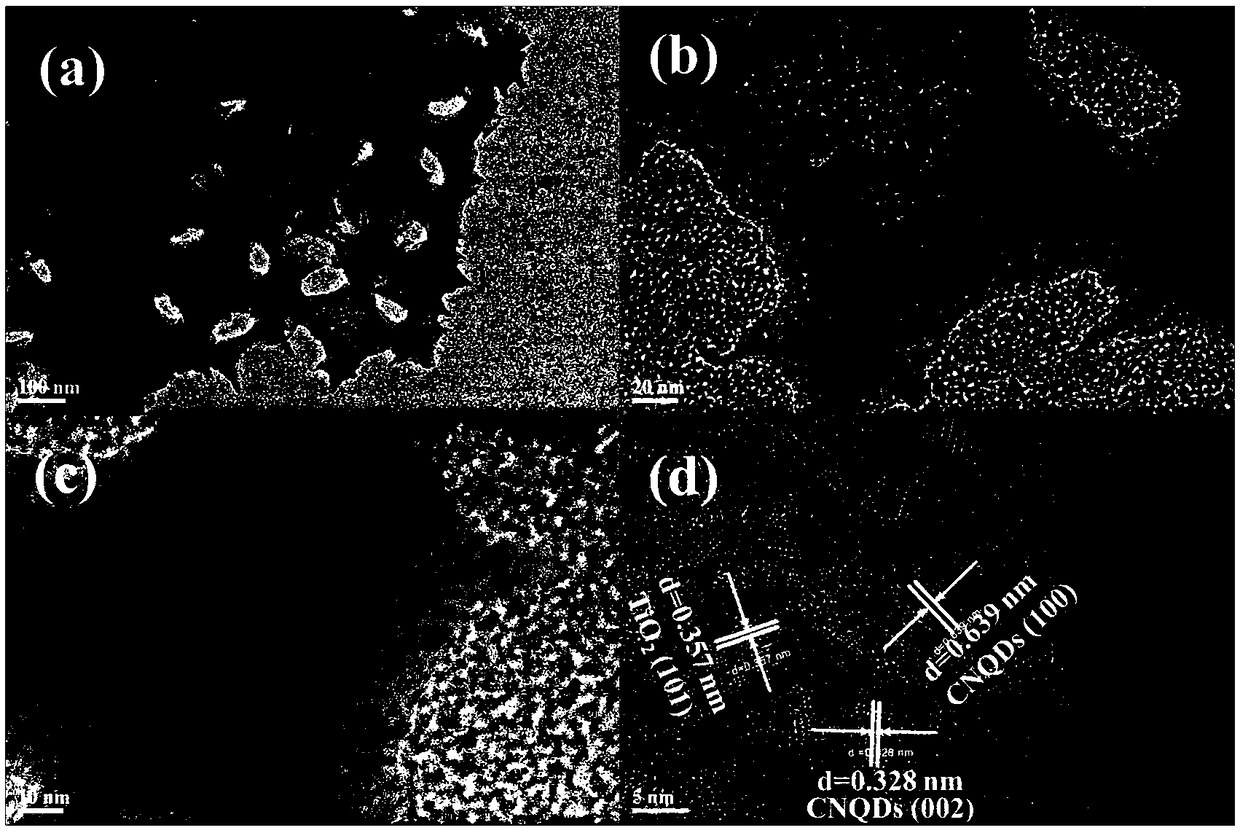

[0028] Preparation of Carbon Nitride Quantum Dots (CNQDs):

[0029] Using urea and sodium citrate as precursors, a low-temperature solid hydrothermal method was used to prepare water-phase carbon nitride quantum dots after dialysis treatment. Specifically, 0.081 g of sodium citrate and 0.101 g of urea were ground and mixed evenly, and then transferred to the lining of a polytetrafluoroethylene reactor. Screw the stainless steel jacket tightly and seal it well, and keep it in an electric heating constant temperature blast drying oven at 180°C for 2h. After taking out the autoclave, let it cool naturally at room temperature, and ultrasonically wash the obtained brown solid three times with absolute ethanol, put it into a dialysis bag of MWCO3500 specification, and dialyze it in 20mL deionized water at room temperature for 24 hours to obtain light yellow carbon nitride quantum dots aqueous solution.

Embodiment 1

[0031] To synthesize Me-TSCN-IO, add carbon nitride quantum dots, pore forming agents such as P123, tetrabutyl silicate and isopropyl titanate during the preparation process, and use polystyrene as a template, specifically:

[0032] After adding 30mL of EtOH into a 50mL beaker, add 2g of P123 and stir for 30min until completely dissolved. Add 0.89mL tetrabutyl silicate (TEOS), 1mL HCl (4mol / L), 1mL inhibitor acetylacetone, 4.8mL isopropyl titanate (TTIP) and 5mL CNQDs aqueous solution into the transparent solution. After stirring at room temperature for 2 h, the precursor solution was perfused into the 355 nm PS template. After 3 days of hydrolysis in a constant temperature and humidity box at a temperature of 40 °C and a humidity of 55%, it was transferred to a 70 °C oven for drying for 3 days, and was calcined in a muffle furnace at 500 °C for 4 hours in an air atmosphere (heating rate 1 °C / min), so that titanium oxide and The carbon nitride quantum dots are compounded in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com