Method for producing xylo-oligosaccharide

A technology of xylo-oligosaccharide and manufacturing method, applied in the directions of sugar production, biochemical equipment and method, glycosylase, etc., to achieve the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0087] Hereinafter, the present invention will be specifically described with reference to Examples and Comparative Examples.

reference example 1

[0089] Pretreatment of biomass containing xylan and cellulose

[0090] Bagasse was used as biomass containing xylan and cellulose for pretreatment. Measure 5 g of bagasse, and heat until it becomes 105°C. Based on the weight change at this time, the solid content rate of bagasse was calculated. The value obtained by multiplying the bagasse in a water-containing state by the water content was defined as the solid content weight. 100 g of bagasse is immersed in an aqueous sodium hydroxide solution in such a manner that the weight of the solid content is 5% by weight in a state mixed with the sodium hydroxide solution, and the amount of sodium hydroxide added to the solid content of the bagasse is 10% by weight. Pretreatment at 80°C for 3 hours. Solid-liquid separation was performed by centrifugation (3,000G, 10 minutes), and it isolate|separated into a solution component and a solid component. The solid content washed with pure water was used in the following experiments as ...

reference example 2

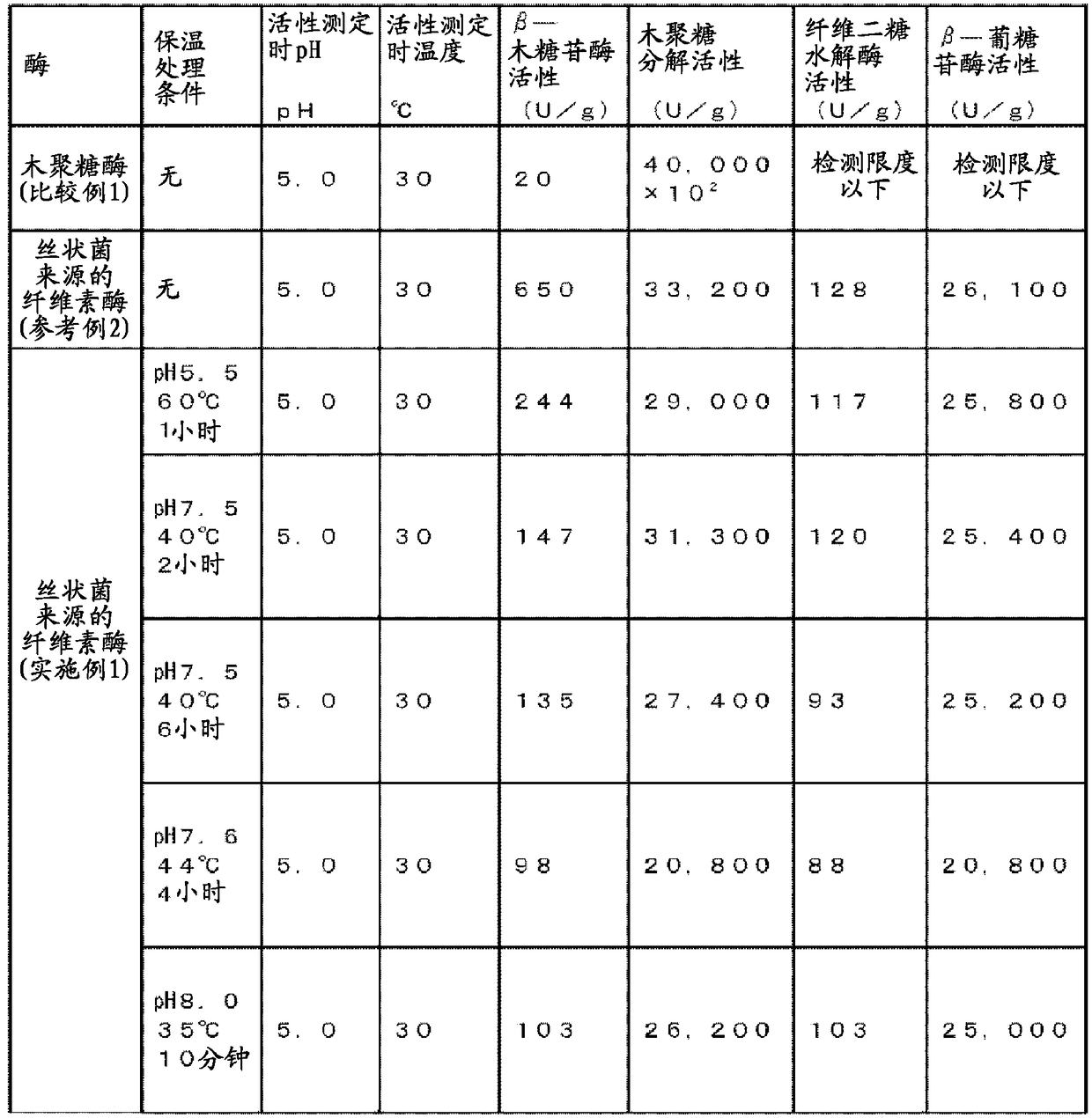

[0092] Modulation of cellulase composition

[0093] [former culture]

[0094] To become corn steep liquor (Corn Steep Liquor) 5% (w / vol), glucose 2% (w / vol), ammonium tartrate 0.37% (w / vol), ammonium sulfate 0.14 (w / vol), potassium dihydrogen phosphate 0.2 % (w / vol), calcium chloride dihydrate 0.03% (w / vol), magnesium sulfate heptahydrate 0.03% (w / vol), zinc chloride 0.02% (w / vol), iron(III) chloride ) hexahydrate 0.01% (w / vol), copper (II) sulfate pentahydrate 0.004% (w / vol), manganese chloride tetrahydrate 0.0008% (w / vol), boric acid 0.0006% (w / vol) , Hexaammonium heptamolybdate tetrahydrate 0.0026% (w / vol) were added to distilled water, 100mL was poured into a 500mL Erlenmeyer flask with a baffle, and autoclaved at 121°C for 15 minutes Sterilization of the sterilizer. After cooling, 0.01% (w / vol) of PE-M and Tween80 which were separately autoclaved at 121° C. for 15 minutes were added to prepare preculture media. In the pre-culture medium 100mL to become 1×10 5 Trichod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com