Lithium-sulfur battery cathode material and preparation method thereof

A positive electrode material, lithium-sulfur battery technology, applied in the field of materials, can solve the problems of reducing the chemical energy storage of lithium-sulfur batteries, hindering application and development, and poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A method for preparing a cathode material for a lithium-sulfur battery provided in an embodiment of the present invention includes:

[0023] S1. Add SnCl dropwise to the uniformly dispersed graphene oxide solution 4 The solution was then stirred evenly, reacted at 175-185°C for 11-13 hours, and then cooled to room temperature to obtain the first product.

[0024] Further, the uniformly dispersed graphene oxide solution was dispersed by ultrasonic for 4 hours.

[0025] In other optional embodiments of the present invention, the above-mentioned graphene oxide solution may also be dispersed using other applicable methods in the art.

[0026] By dispersing the above-mentioned graphene oxide, the graphene oxide solution can be effectively prevented from agglomerating, thereby ensuring good performance of the subsequently prepared lithium-sulfur battery cathode material.

[0027] Further, in this embodiment, the above-mentioned graphene oxide solution can be self-made or pu...

Embodiment 1

[0056] A cathode material for a lithium-sulfur battery provided in this embodiment is prepared as follows:

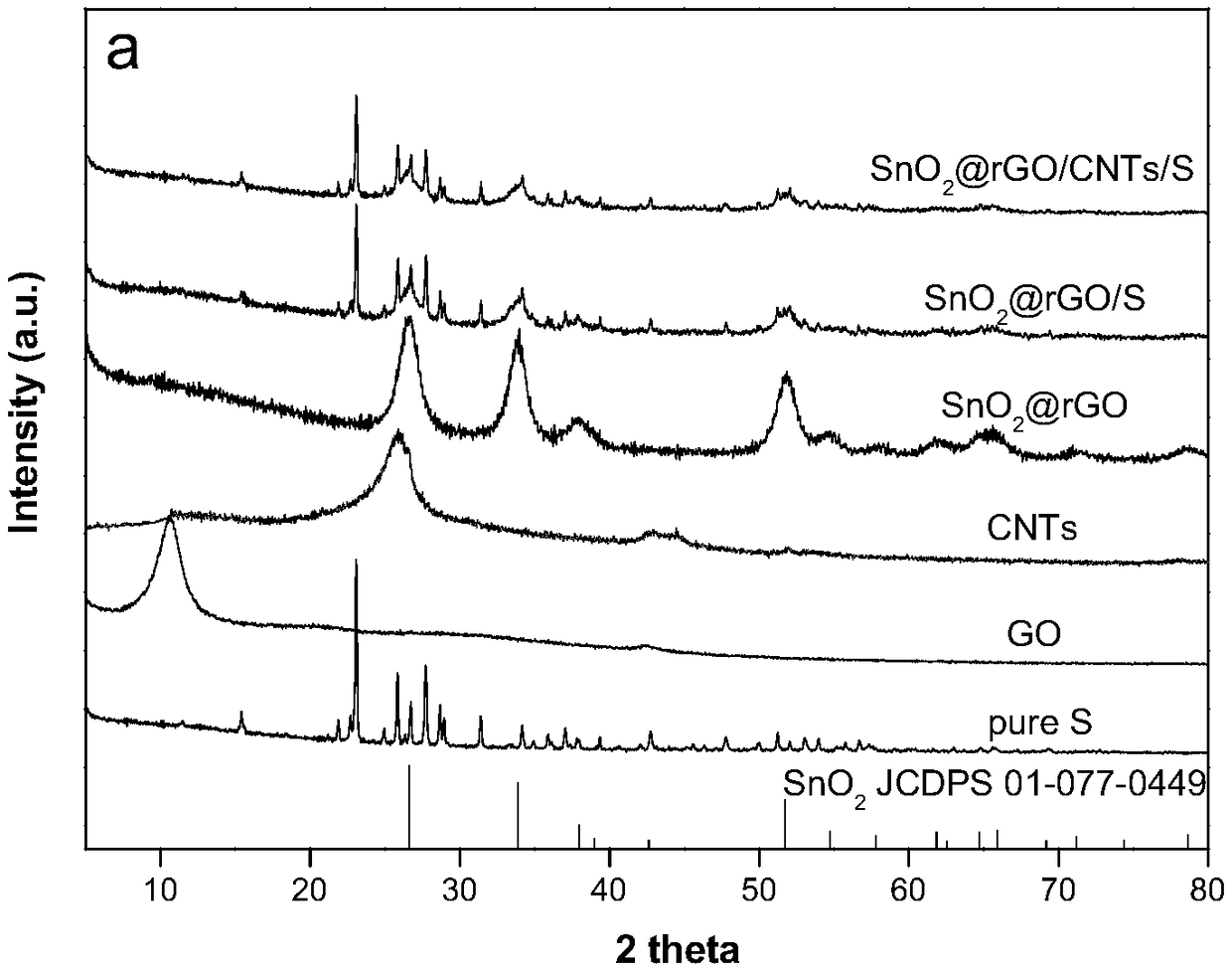

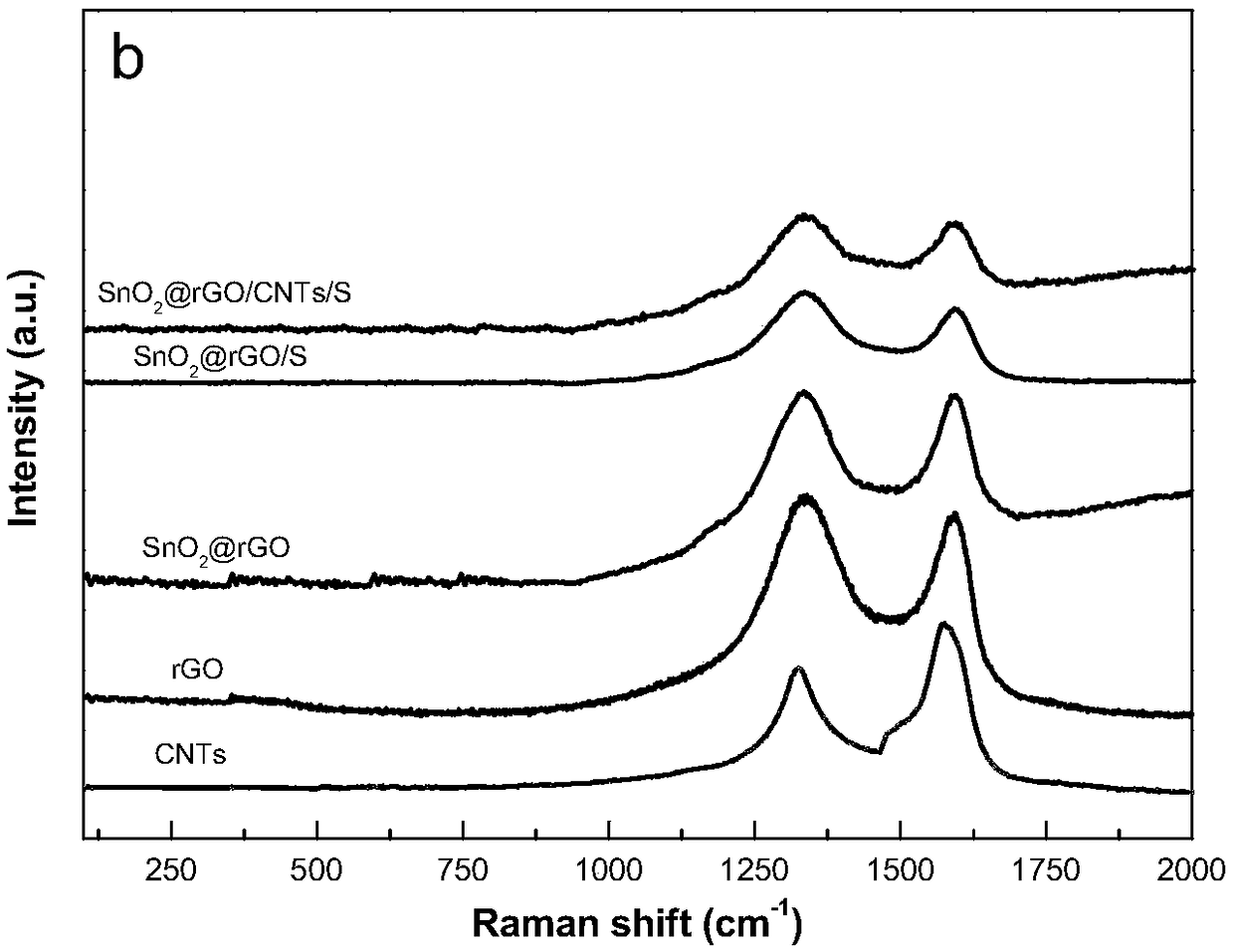

[0057] Weigh 90mg of GO and add it into 30ml of deionized water, sonicate for 4h to obtain GO dispersion; weigh 0.7g of SnCl 4 ﹒ 5H 2 O was dissolved in 5ml of deionized water, and the GO dispersion was slowly dropped into the GO dispersion using a constant flow pump. After stirring for 30 minutes, the solution was transferred to a 50ml autoclave, reacted at 180°C for 12 hours, cooled to room temperature, and washed by centrifugation. ℃ drying. Under Ar atmosphere, 5°C min -1 Calcined at 450°C for 2 hours, cooled to room temperature to obtain the product, marked as SnO 2 @rGO.

[0058] Weigh SnO according to the mass ratio of 2:1 2 Put @rGO and CNTs into a PTFE ball mill jar, using agate balls Ball mill for 30min at a speed of 200r / min to obtain SnO 2 @rGO / CNTs. The prepared SnO 2 @rGO / CNTs and elemental S were uniformly ground in a certain proportion and the...

Embodiment 2

[0060] A cathode material for a lithium-sulfur battery provided in this embodiment is prepared as follows:

[0061] Weigh 90mg of GO and add it into 30ml of deionized water, sonicate for 4h to obtain GO dispersion; weigh 0.7g of SnCl 4 ﹒ 5H 2 O was dissolved in 5ml of deionized water, and the GO dispersion was slowly dropped into the GO dispersion using a constant flow pump. After stirring for 30 minutes, the solution was transferred to a 50ml autoclave, and reacted at 175°C for 11 hours. After cooling to room temperature, it was centrifuged and washed. ℃ drying. Under Ar atmosphere, 5°C min -1 Calcined at 440°C for 1.5h, cooled to room temperature to obtain the product, marked as SnO 2 @rGO.

[0062] Weigh SnO according to the mass ratio of 2:1 2 Put @rGO and CNTs into a PTFE ball mill jar, using agate balls Ball mill for 30min at a speed of 200r / min to obtain SnO 2 @rGO / CNTs. The prepared SnO 2 @rGO / CNTs and elemental S were uniformly ground in a certain proportio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com