Phosphoric acid production parameter control method based on gradient boosted decision tree

A production parameter and decision tree technology, which is applied in the field of soft measurement of phosphate rock consumption based on gradient lifting decision tree, phosphoric acid production parameter control field based on gradient lifting decision tree, and can solve the problem of unstable phosphate rock loader metering, etc. problem, achieve the effect of reducing training time, ensuring accuracy, and reducing measurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

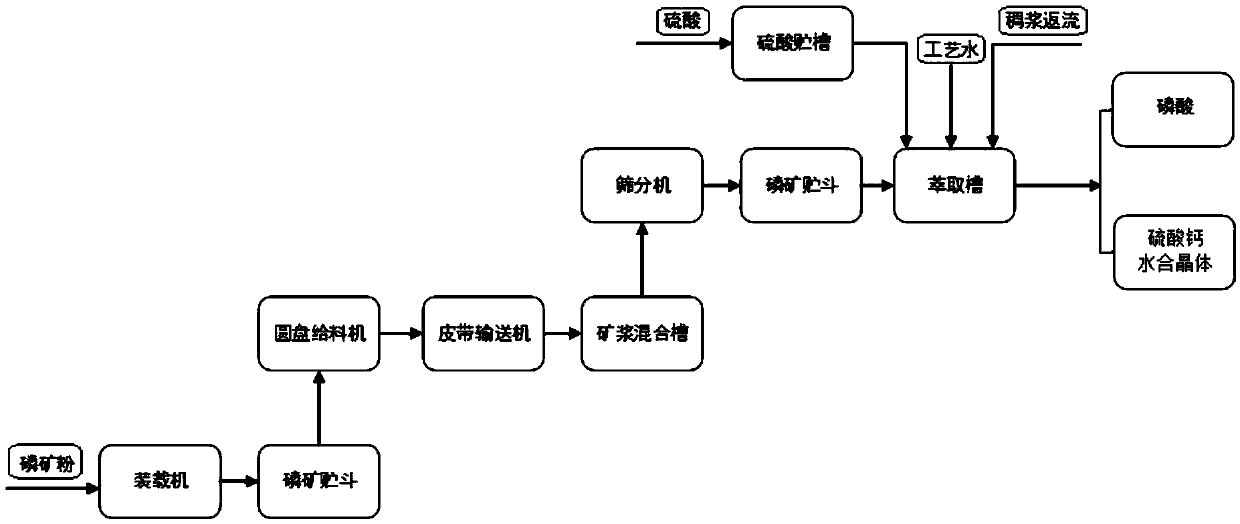

[0051] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. Embodiment: A method for controlling phosphoric acid production parameters based on a gradient boosting decision tree, including a method for soft-sensing consumption of phosphate rock and a step for controlling phosphoric acid production parameters.

[0052] like figure 1 As shown, the soft sensing method for phosphate rock consumption based on the gradient boosting decision tree includes the following steps:

[0053] The consumption of phosphate rock powder is not easy to measure directly in the production process of feed grade calcium hydrogen phosphate. Now, the historical data of mineral powder pulping section and phosphoric acid extraction section of a domestic feed grade calcium phosphate production plant are collected as the data source for training models. Through data cleaning and data convers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com