A method for treating sludge by chemical looping gasification based on copper slag as an oxygen carrier and a device for realizing the method

An oxygen carrier and chemical chain technology, which is applied in the fields of clean fuel gasification, functional materials and environmental protection, can solve the problems of increasing the cost of sludge gasification treatment, secondary pollution, waste of land resources, etc., and is conducive to stable operation. , The purification cost is low, and the effect of ensuring the feeding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

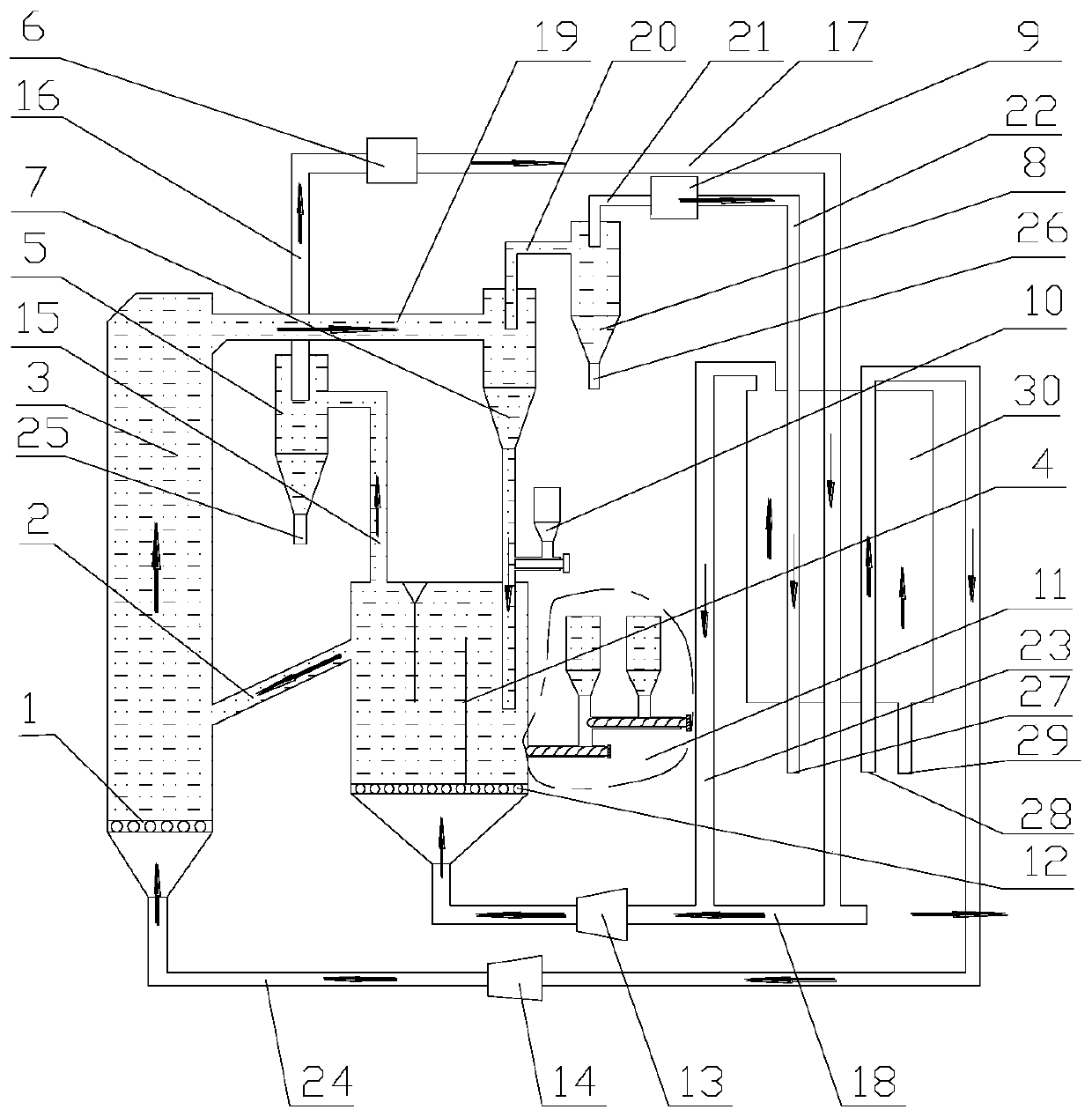

Method used

Image

Examples

Embodiment 1

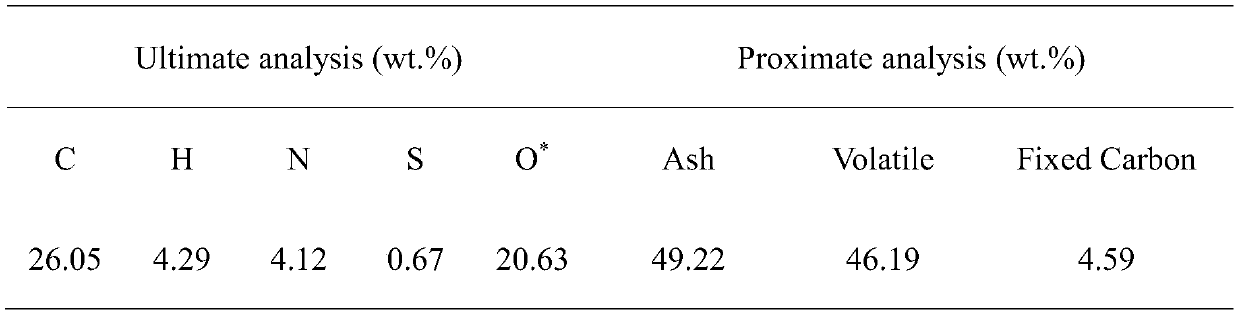

[0032] 1) Preparation of oxygen carrier and sludge:

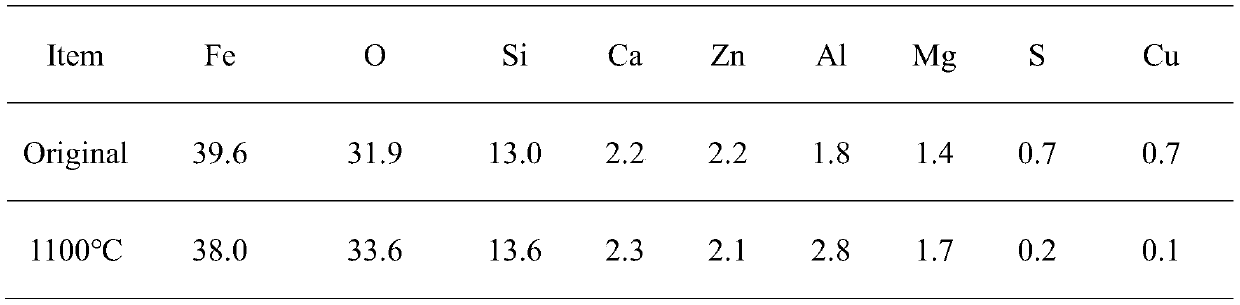

[0033] Using the original copper slag provided by Nanjing Iron and Steel Works as the matrix, first crush it, the average particle size is about 1mm; place it evenly in the high-temperature muffle furnace, the accumulation thickness is 15mm, and start from room temperature at 15°C / min Raise to 1100°C and keep the temperature constant for 2 hours. During the calcination process, fresh air is continuously introduced into the furnace to realize air calcination, and then naturally cool to room temperature; take out, crush, sieve (100 mesh), and store to obtain the target oxygen carrier. The elemental analysis of copper slag and copper slag calcined at 1100°C is shown in Table 1. Calcination increases the content of oxygen in the oxygen carrier because of the decomposition reaction of iron silicate (Eq.1). 2Fe 2 SiO 4 +(Sufficient)O 2 →2Fe 2 o 3 +2SiO 2 (Eq.1)

[0034] Table 1. Elemental analysis of original copper slag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com