Heating system of large-scale pure condensing-type steam turbine generator set and heating method

A technology of steam turbine generator set and heating system, which is applied in the direction of steam central heating system, heating system, heating method, etc., can solve the problem of high unit load requirements, limited heating operation mode, incomplete heating system, etc. problems, to achieve the effect of increasing the temperature of the steam supply and preventing the damage of the blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

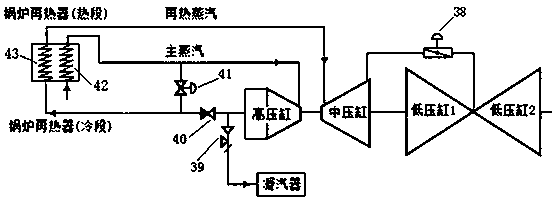

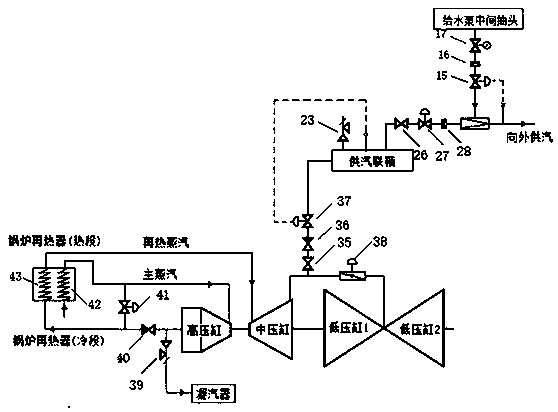

[0068] Take the steam turbine model N300-16.7 / 538 / 538-9 subcritical, one-time intermediate reheat, two-cylinder, two-exhaust, pure condensing gas unit for heat supply transformation project application as an example. The requirements for heating steam are: the pressure of the steam header 25 is 0.75 MPa (gauge pressure, the pressure unit in the text is gauge pressure); the temperature of the steam supply is required to be greater than 280 °C; the design steam flow rate of the steam supply is 150 t / h. Since the steam supply pressure requirement is not high, steam can be extracted from the medium and low pressure cylinder Unicom pipe for heating. This project adopts the steam supply header 25, the Unicom pipe disc valve 38, the corresponding pipelines, valves and flow, pressure, temperature measuring devices, such as image 3 shown.

[0069] During the test, under the premise that the pressure and temperature of the steam supply meet the requirements of the heating steam paramet...

Embodiment 2

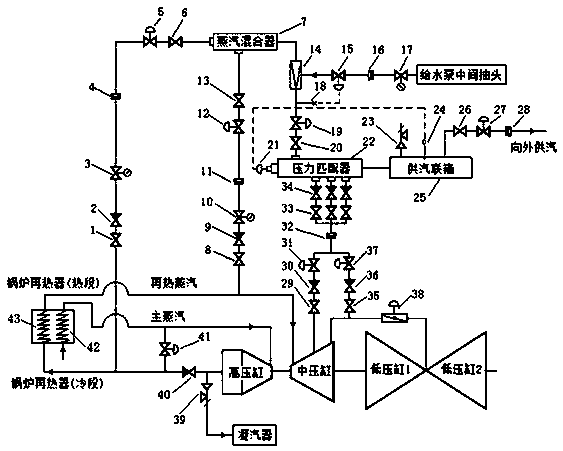

[0073] Take the steam turbine model N320-16.7 / 537 / 537-2 subcritical, one-time intermediate reheat, two-cylinder two-exhaust, pure condensing gas unit for heat supply transformation project application as an example. The requirements for heating steam are: steam header 25 pressure 1.50 MPa, steam supply temperature requirement 355 °C; design heat supply flow rate 150 t / h; terminal steam supply parameters: 1.00 MPa, 240 °C. When the maximum output of the unit is 330MW, the maximum exhaust pressure of the medium-pressure cylinder is 0.84 MPa, so the steam extraction from the connecting pipe of the medium-low pressure cylinder cannot reach the 1.50 MPa pressure required by the 25 pressure of the steam header. The cold section or hot section of the heater extracts steam. For this reason, the project adopts a pressure distributor 22, a steam supply header 25, and corresponding pipelines, valves, and flow, pressure, and temperature measurement devices, such as Figure 4 shown. Durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com