Method for quickly balancing stress after hydraulic punching

A hydraulic punching and stress technology, which is applied in earthwork drilling, gas discharge, mining fluid, etc., can solve problems such as increasing difficulty, reducing coal quality, and reducing drilling utilization, so as to prevent uneven stress distribution and improve coal seam Gas drainage rate, effect of increasing effective drainage radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

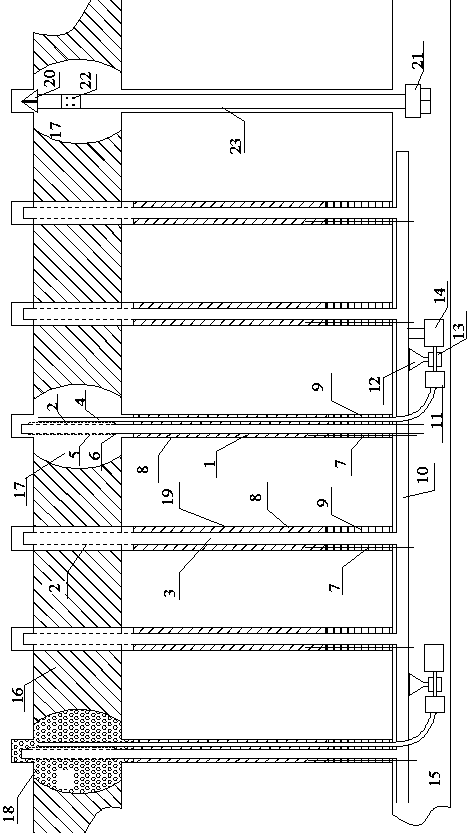

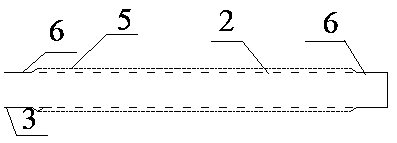

[0042] Such as figure 1 and figure 2 As shown, a method for quickly balancing stress after hydraulic punching, the filling device includes a drainage screen 2, a sealing pipe 3, a filling pipe 4, a liquid storage tank 14, a coal particle bin 12, a mixing device 13 and an injection Slurry pump 11, the extraction screen 2 is arranged in the punching hole 17, and the screen 5 is fixed on the outside of the extraction screen 2; the lower part of the extraction screen 2 is connected with the sealing pipe 3, and the sealing pipe 3 is set In the extraction borehole 19, the lower part of the sealing pipe 3 is connected with the extraction branch pipe 10 arranged in the bottom extraction lane 15; The slurry pump 11, the lower part of the filling pipe 14 is connected with the mixing device 13, and the mixing device 13 is connected with the liquid storage tank 14 and the coal particle bin 12 respectively.

[0043] The screen 5 is a 16-mesh screen. The screen 5 is a cylindrical screen....

Embodiment 3

[0047] Such as figure 1 and figure 2 As shown, a rapid balance method of stress after hydraulic punching is aimed at gas control in soft and low-permeability coal seams. In this example, the main mining seam is the second 1 Coal, coal thickness 3.2m, relative gas content is 16m 3 / t, the gas pressure is 1.4MPa, the steps are as follows:

[0048] (1) Construct the upward punching hole 1 in the bottom pumping roadway 15. When the drill bit 25 enters the roof of the coal seam 16, shut down the drilling rig 26 and connect high-pressure water. The high-pressure water reaches the punching nozzle 27 through the drill pipe 28 for hydraulic Punching, forming punching hole 17, and recording the amount of coal produced is 2.1m 3 , and then move the drilling rig 26 to carry out the next group of drainage drilling 19;

[0049] (2) After the extraction borehole 19 drills through the coal seam 16, the drill pipe 28 is directly withdrawn, the extraction screen 2 and the sealing pipe 3 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com