Egg yolk phosphatidyl choline preparation method based on low-pressure column chromatography

A technology of egg yolk phosphatidylcholine and phosphatidylcholine, which is applied to edible phospholipid compositions, chemical instruments and methods, protein food ingredients, etc., can solve problems such as high equipment cost, small processing capacity, and heavy metal ion residues, and achieve The effect of simple operation process, high production efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

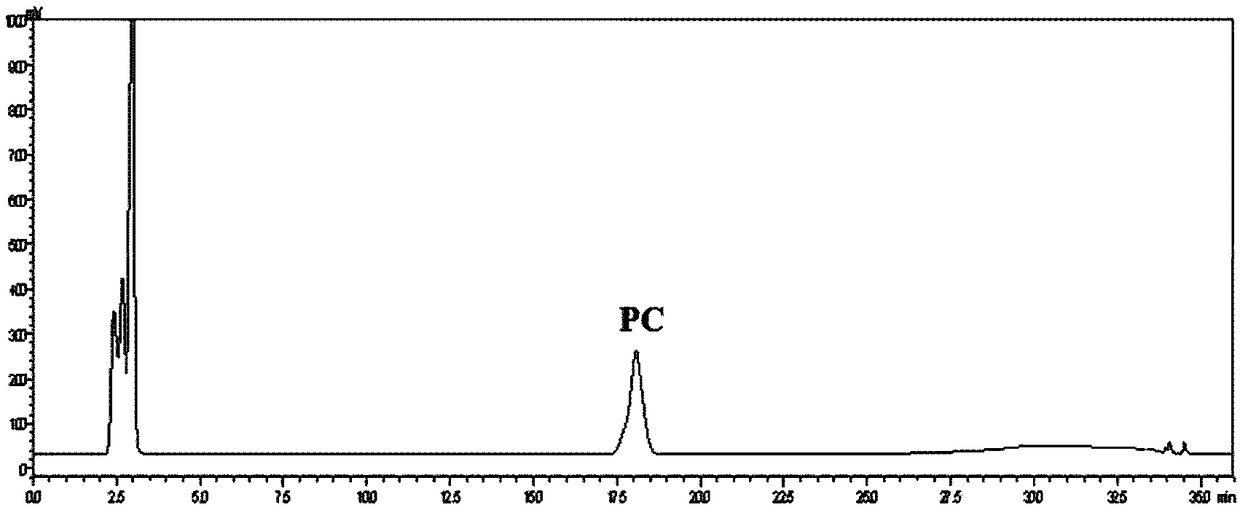

Image

Examples

Embodiment 1

[0033] S1. Filler activation: Weigh 15g of mixed silica gel powder with a mesh number of 200-300, and activate it in an oven at 50°C for 6 hours;

[0034] S2, column packing: choose a glass chromatography column with a length of 200 mm and a diameter of 16 mm to separate and purify phosphatidylcholine (PC), add 30 mL of chloroform to the activated silica gel powder in step S1 and stir it into a slurry, and use a wet method The column packing method puts silica gel into a glass chromatography column to obtain a silica gel column;

[0035] S3. Dissolve 200 mg of egg yolk crude phospholipids in 1 mL of chloroform and slowly add them into the silica gel chromatography column prepared in step S2 along the column wall;

[0036] S4. Gradient elution: use 20 times the column volume of chloroform, methanol, and glacial acetic acid ternary mixed solvent (chloroform:methanol:glacial acetic acid=18:5:1, volume ratio) for the first elution, remove the After the pigment and other phospholi...

Embodiment 2

[0040] S1. Filler activation: Weigh 15g of silica gel powder with a mesh number of 200-300, and activate it in an oven at 55°C for 5h;

[0041] S2, column packing: choose a glass chromatography column with a length of 200 mm and a diameter of 16 mm to separate and purify phosphatidylcholine (PC), add 35 mL of chloroform to the activated silica gel powder in step S1 and stir it into a slurry, and use a wet method The column packing method puts silica gel into a glass chromatography column to obtain a silica gel column;

[0042] S3. Dissolving 150 mg of egg yolk crude phospholipids in 1 mL of chloroform and slowly adding to the silica gel chromatography column prepared in step S2 along the column wall;

[0043]S4. Gradient elution: first elute with 15 times the column volume of chloroform, methanol, and glacial acetic acid ternary mixed solvent (chloroform:methanol:glacial acetic acid=17:5:1, volume ratio) for the first elution, remove the After the pigment and other phospholip...

Embodiment 3

[0047] S1. Filler activation: Weigh 15g of silica gel powder with a mesh number of 200-300, and activate it in an oven at 60°C for 4 hours;

[0048] S2, column packing: choose a glass chromatography column with a length of 200 mm and a diameter of 16 mm to separate and purify phosphatidylcholine (PC), add 40 mL of chloroform to the activated silica gel powder in step S1 and stir it into a slurry, and use a wet method The column packing method puts silica gel into a glass chromatography column to obtain a silica gel column;

[0049] S3. Dissolve 300 mg of egg yolk crude phospholipids in 1 mL of chloroform and slowly add them into the silica gel chromatography column prepared in step S2 along the column wall;

[0050] S4. Gradient elution: use 10 times the column volume of chloroform, methanol, and glacial acetic acid ternary mixed solvent (chloroform:methanol:glacial acetic acid=18:5:1, volume ratio) for the first elution, remove the After the pigment and other phospholipid co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com