Macromolecular quick-dissolving fertilizer for vegetables and preparation method thereof

A polymer, instant technology, applied in the direction of layered/coated fertilizer, application, nitrogen fertilizer, etc., can solve the problems of adverse consequences of the living environment and ecological environment, restricting the sustainable development of the vegetable industry, and difficult to popularize and use in a large area. Achieve the effect of avoiding physiological diseases, promoting absorption and utilization, and strong lodging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

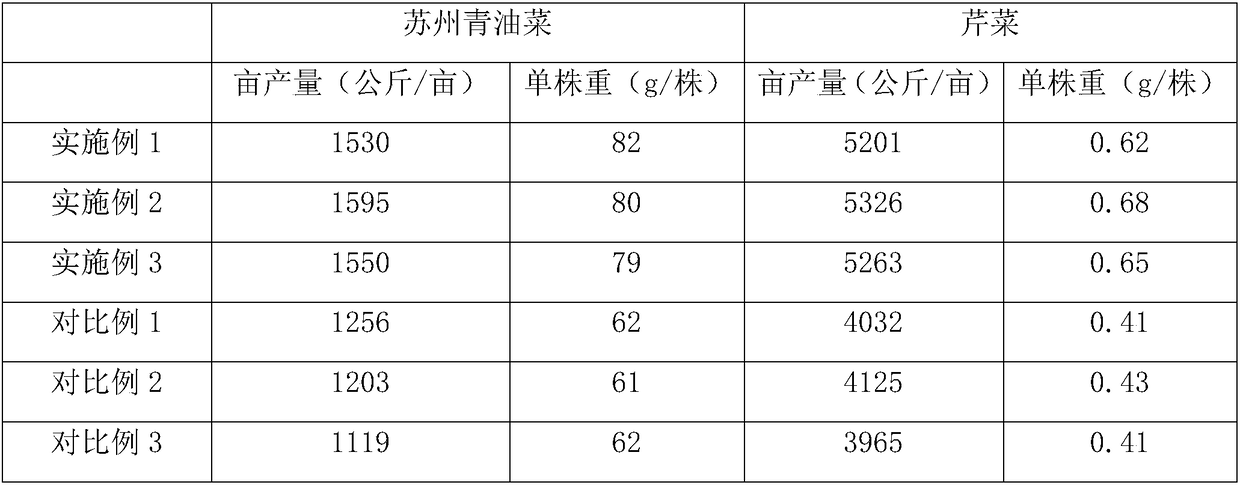

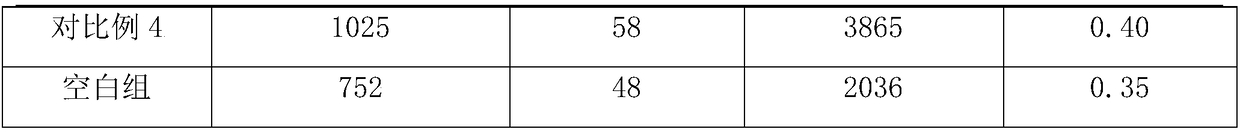

Examples

Embodiment 1

[0021] A special polymer instant fertilizer for vegetables, which is made of the following raw materials in parts by weight: 40 parts of urea, 20 parts of potassium dihydrogen phosphate, 15 parts of potassium sulfate, 5 parts of boron sulfate, 3 parts of magnesium sulfate, and 3 parts of calcium sulfate , 1 part of humate, 10 parts of water-soluble chitosan, 1 part of synergist, 3 parts of anti-caking agent, 1 part of accelerator;

[0022] The synergist is formed by mixing polyaspartic acid, pullulan and potassium fulvic acid according to 1:2-4:4-6;

[0023] The anti-caking agent is made of pullulan-polyglutamic acid cross-linked polymer and sodium methylnaphthalenesulfonate according to the weight ratio of 1:1; the accelerator is polyacrylamide, fatty alcohol polyoxygen Sodium vinyl ether sulfate and tetrasodium iminodisuccinate are composed in a weight ratio of 0.8:1:1.

[0024] The pullulan-polyglutamic acid cross-linked polymer is prepared by the following method: the pul...

Embodiment 2

[0032] A special polymer instant fertilizer for vegetables, which is made of the following raw materials in parts by weight: 80 parts of urea, 60 parts of potassium dihydrogen phosphate, 45 parts of potassium sulfate, 15 parts of boron sulfate, 8 parts of magnesium sulfate, and 10 parts of calcium sulfate , 10 parts of humate, 20 parts of water-soluble chitosan, 3 parts of synergist, 8 parts of anti-caking agent, and 5 parts of accelerator;

[0033] The synergist is formed by mixing polyaspartic acid, pullulan and potassium fulvic acid according to 1:2-4:4-6;

[0034]The anti-caking agent is made of pullulan-polyglutamic acid cross-linked polymer and sodium methylnaphthalenesulfonate according to the weight ratio of 1:1; the accelerator is polyacrylamide, fatty alcohol polyoxygen Sodium vinyl ether sulfate and tetrasodium iminodisuccinate are composed in a weight ratio of 0.8:1:1.

[0035] The pullulan-polyglutamic acid cross-linked polymer is prepared by the following method...

Embodiment 3

[0043] A special polymer instant fertilizer for vegetables, which is made of the following raw materials in parts by weight: 60 parts of urea, 40 parts of potassium dihydrogen phosphate, 30 parts of potassium sulfate, 10 parts of boron sulfate, 5 parts of magnesium sulfate, and 7 parts of calcium sulfate , 5 parts of humate, 15 parts of water-soluble chitosan, 2 parts of synergist, 5 parts of anti-caking agent, 3 parts of accelerator;

[0044] The synergist is formed by mixing polyaspartic acid, pullulan and potassium fulvic acid according to 1:2-4:4-6;

[0045] The anti-caking agent is made of pullulan-polyglutamic acid cross-linked polymer and sodium methylnaphthalenesulfonate according to the weight ratio of 1:1; the accelerator is polyacrylamide, fatty alcohol polyoxygen Sodium vinyl ether sulfate and tetrasodium iminodisuccinate are composed in a weight ratio of 0.8:1:1.

[0046] The pullulan-polyglutamic acid cross-linked polymer is prepared by the following method: the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com