Method for chemically treating sludge and application

A chemical treatment and sludge technology, applied in the oxidation treatment of sludge, chemical instruments and methods, botanical equipment and methods, etc., can solve the problems of long curing time curing and maintenance, difficulty in ensuring the consistency of cured mortar, and high labor costs. Achieving a good root ecological environment, promoting harmless natural degradation and sufficient nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

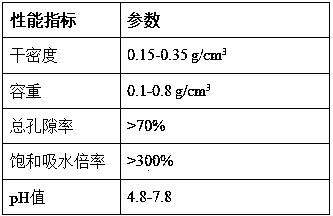

Embodiment 1

[0020] Collect 100kg of sludge with a moisture content of 85%, add 0.05kg of sodium phosphate, 1kg of grass seeds, 3kg of zeolite powder, 3kg of diatomaceous earth, 3kg of bentonite, 5kg of crushed straw, 0.3kg of hydrochloric acid, and 0.05kg of dodecyl Trimethylammonium chloride, 15kg of polyvinyl formal solution, 10kg of polyurethane prepolymer, stir quickly and spread evenly on the bare green belt, the thickness of the spread is about 2-3cm, foam after 1-20 minutes Fixed and molded to obtain a porous growth matrix layer with a thickness of about 4-8 cm. Pour water on the substrate layer, the water can penetrate quickly, and the water absorption rate is 2-5 times. After the water absorption is supersaturated, the oozing water is transparent, which shows that the polymer bonding material can effectively cover and protect the particles such as silt. interception effect. After 7-15 days of maintenance, young grass shoots can grow, providing a good growth environment for herbs...

Embodiment 2

[0024] Add 1000 kg of water, 100 kg of kaolin, 50 kg of vermiculite, 50 kg of perlite, 100 kg of diatomite, 3 kg of triethanolamine, 1.5 kg of polyoxyethylene ether nonionic surfactant, 0.05 kg of EDTA into the mixing tank Sodium, 3 kilograms of hydrogen peroxide, 50 kilograms of melamine resins, stir to obtain component 1;

[0025] There are 4 feeding ports A, B and C connected to the splicing mixing head. The feeding port A is a slurry with a water content of 75%; the feeding port B is connected to the above component 1; the feeding port C is connected to the polyurethane prepolymerization Body, prepolymer NCO content 12%; start the splicing mixing head, start A, B, C feed pumps at the same time, mix according to the feed ratio of 4:2:1 and spray it on the slope after surface fixing treatment, Under normal temperature and pressure, the reaction is finalized for 1-60 minutes to obtain a plant growth matrix layer for slope protection. The substrate layer is continuous, dust-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com