Production process of metal composite plate

A metal composite board and production process technology, which is applied in the direction of layered products, lamination devices, lamination auxiliary operations, etc., can solve the problems of inaccurate control of the curing reaction process, narrow use temperature range, long production line length, etc., to achieve guaranteed The effect of production process requirements and product quality, ensuring production process requirements, and saving investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

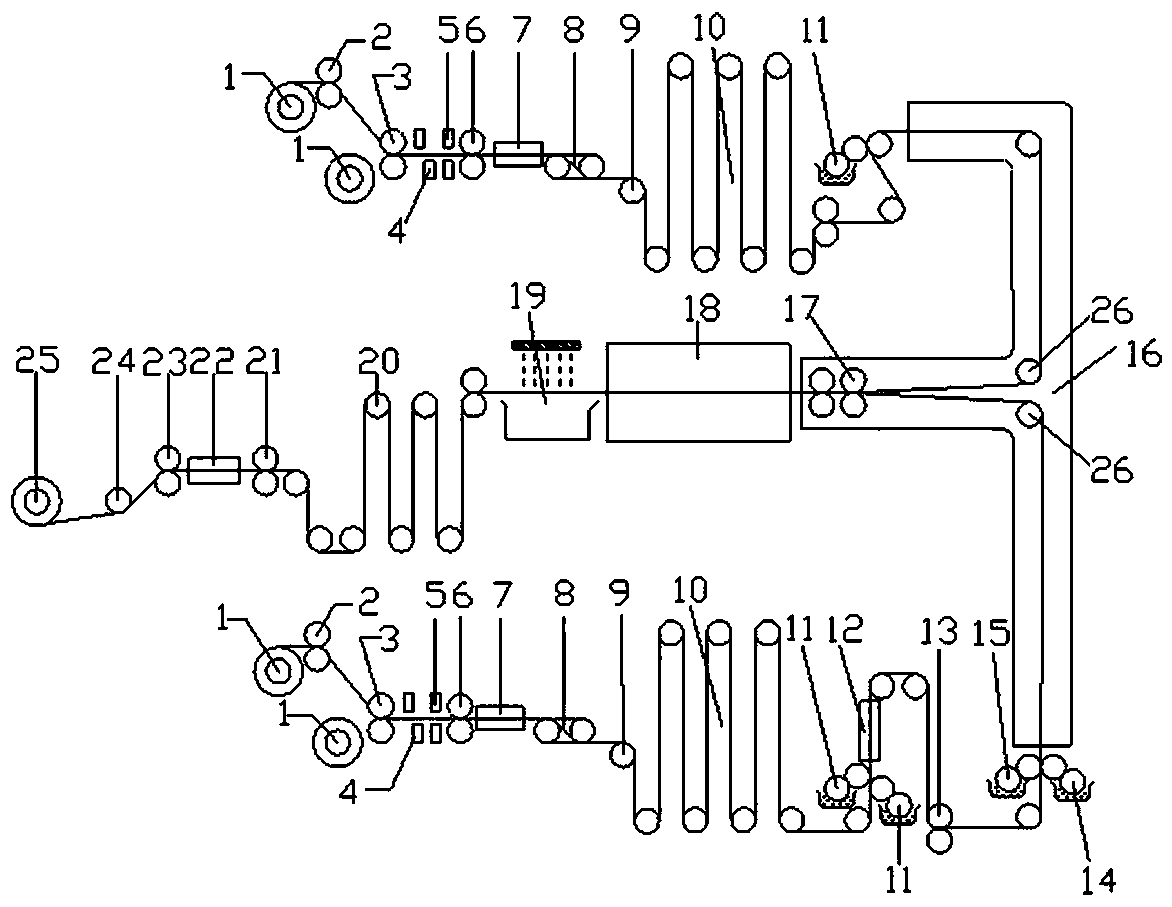

[0016] Referring to the accompanying drawings, the production process of this composite board is as follows: after the upper aluminum coil and the lower zinc-aluminum-magnesium coil are treated by the surface treatment unit 7, a layer of chemical coating solution is respectively coated on the coating surface described in the manual by the chemical coating machine 11, The upper aluminum coil directly enters the F-shaped drying furnace 16 for drying and preheating treatment; the lower zinc-aluminum-magnesium coil passes through the chemical coating drying furnace 12 for drying, and then coats a layer of liquid polyurethane coating and liquid coating on the upper and lower surfaces respectively. The polymer resin enters the F-shaped drying furnace 16 to complete the solvent volatilization, and the preheating temperature is 200°C; and the compounding unit 17 completes the compounding, and the rolling pressure of the compounding roll is 80t; then the curing process is completed by th...

Embodiment 2

[0018] Referring to the accompanying drawings, the production process of this composite panel is: after the upper galvanized coil and the lower galvanized coil are treated by the surface treatment unit 7, a layer of chemical coating solution is respectively coated on the coating surface described in the manual by the chemical coating machine 11, The upper layer of aluminum coil directly enters the F-shaped drying furnace 16 for drying and preheating; the lower layer of zinc, aluminum and magnesium coils is dried through the chemical coating drying furnace 12, and then coated with a layer of liquid epoxy resin coating on the upper and lower surfaces respectively. and liquid polymer resin, enter the F-shaped drying furnace 16 to complete solvent volatilization, and the preheating temperature is 300 ° C; and complete the compounding by the composite unit 17, and the rolling pressure of the composite roll is 100t; The cooling equipment 19 is forced to cool down to normal temperatur...

Embodiment 3

[0020]Referring to the accompanying drawings, the production process of this composite board is as follows: after the upper layer of red copper coil and the lower layer of aluminum coil are treated by the surface treatment unit 7, a layer of chemical coating solution is respectively coated on the coating surface described in the manual by the chemical coating machine 11, and the upper layer of copper The coil directly enters the F-shaped drying furnace 16 for drying and preheating; the lower aluminum coil passes through the chemical coating drying furnace 12 for drying, and then coats a layer of liquid polymer resin on the lower surface and enters the F-shaped drying furnace 16. Solvent volatilization is completed, and the preheating temperature is 150°C; compounding is completed by the compounding unit 17, and the rolling pressure of the compounding roll is 30t; then the curing process is completed by the curing unit 18, and the cooling device 19 is forced to cool to normal tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com