Hermetic Compressor

a compressor and hermetic technology, applied in the direction of positive displacement liquid engines, piston pumps, liquid fuel engines, etc., can solve the problems of increasing components, reducing thermal efficiency, unsatisfactory lubrication, etc., and achieves simple structure, reduced costs, and simplified upper structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

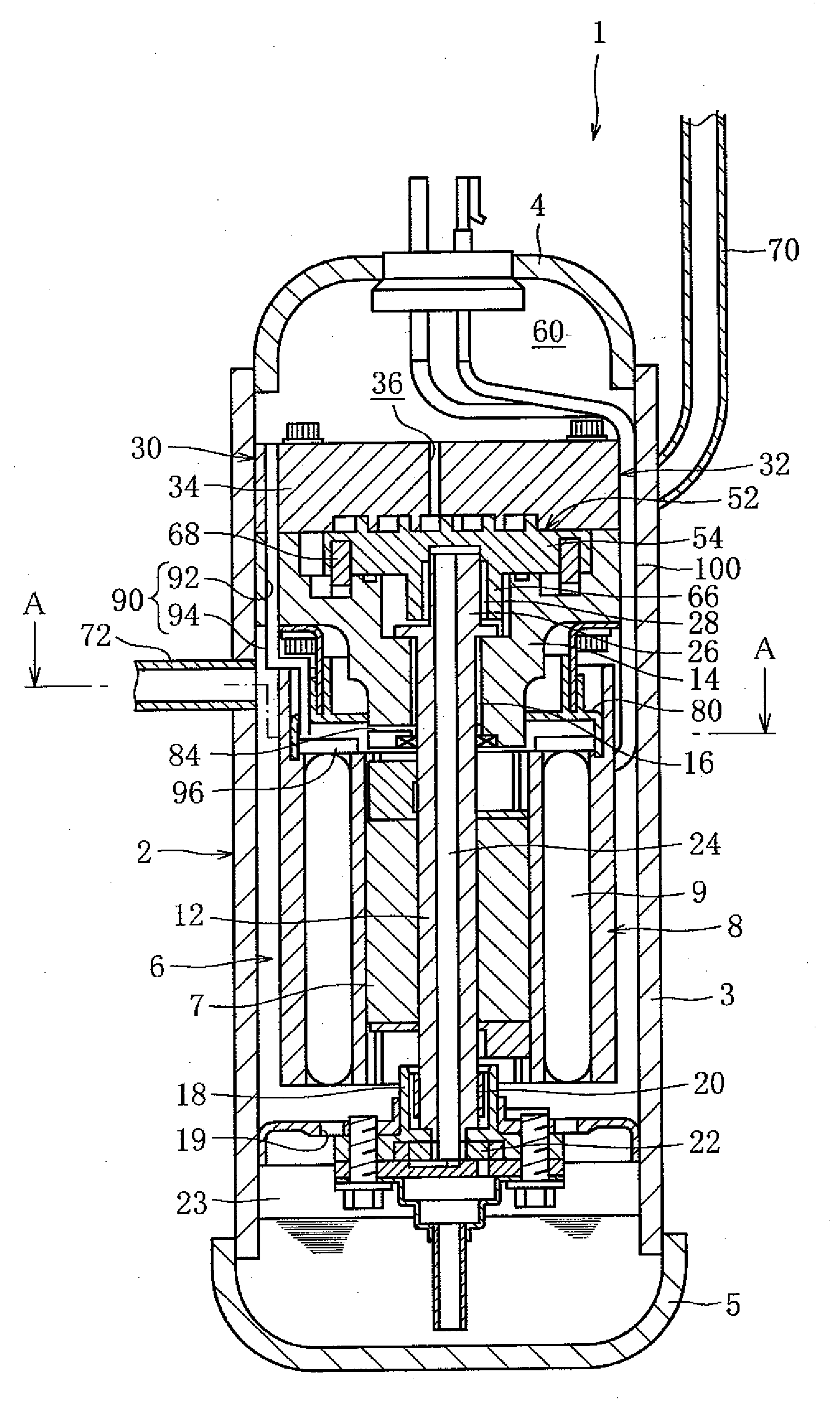

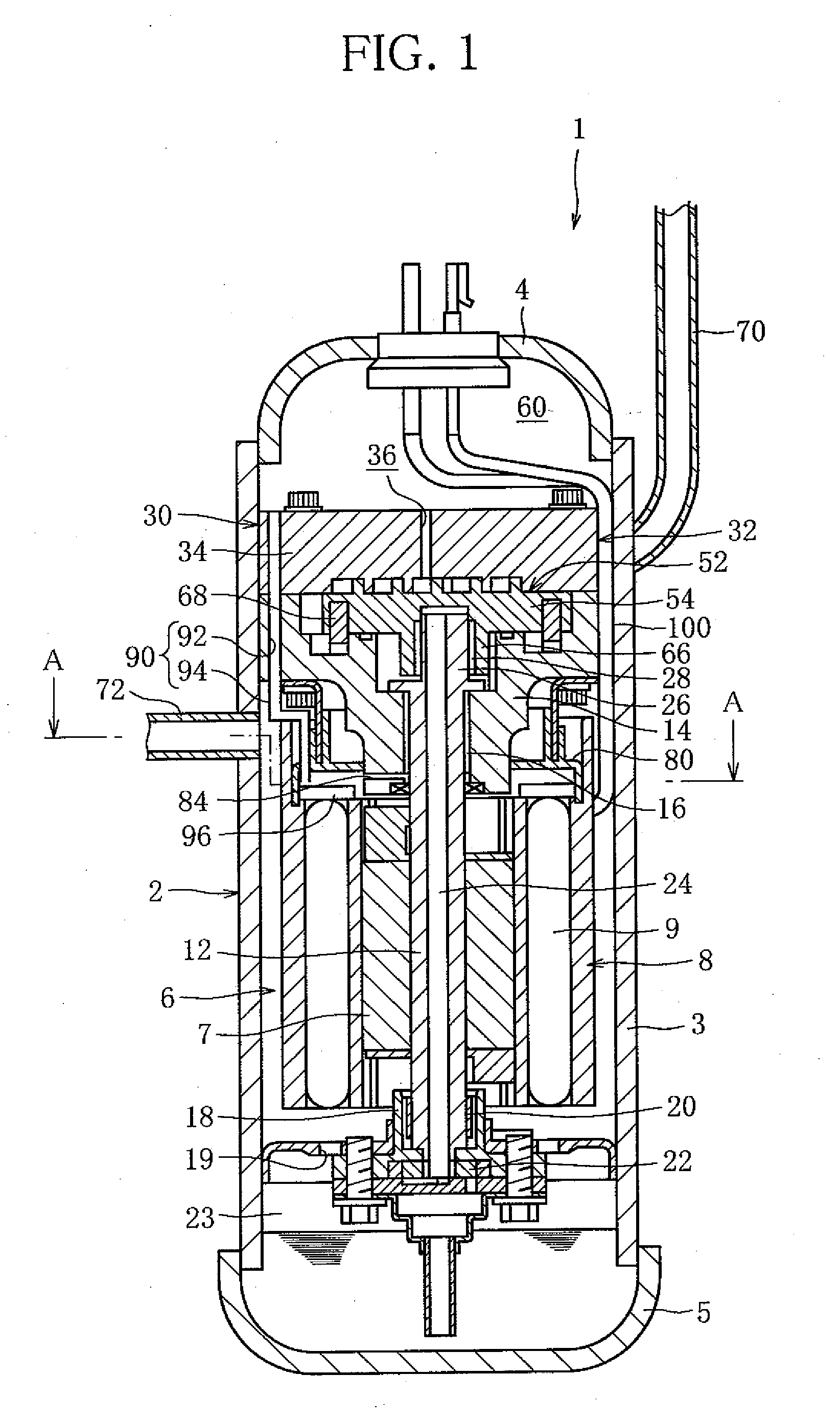

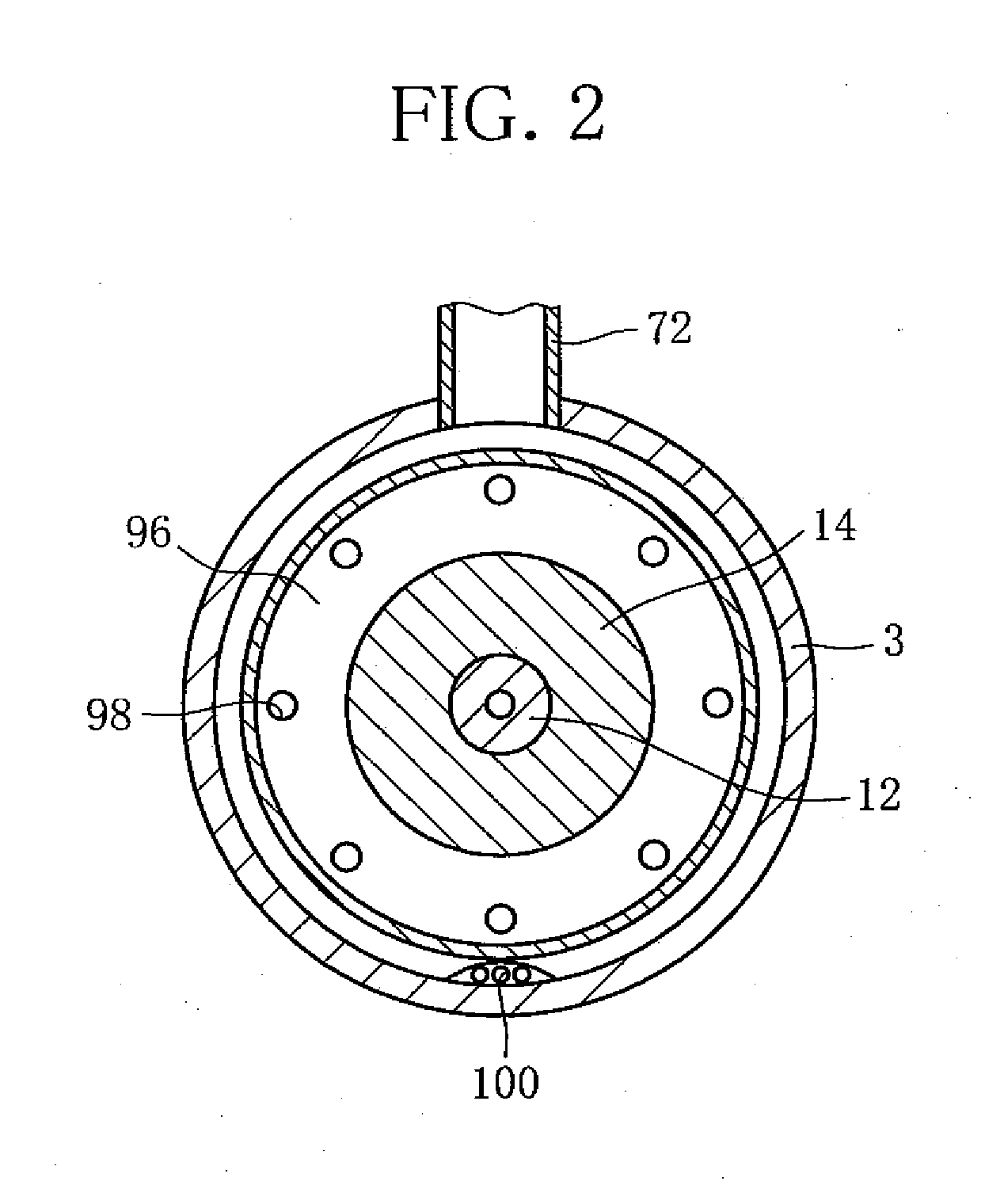

FIG. 1 is a vertical cross-sectional view of a hermetic compressor according to the present invention. The compressor 1 is a scroll compressor and incorporated in a refrigeration circuit of a refrigeration system, a heat pump water heater or the like. The circuit provides a path along which carbon dioxide refrigerant (hereinafter referred to simply as “refrigerant”), which is an example of a working fluid, circulates. The compressor 1 sucks in and compresses the refrigerant, thereby forcing it to circulate along the path.

The compressor 1 has a housing (hermetic container) 2. A body 3 of the housing 2 is hermetically sealed with upper and lower covers 4, 5 hermetically fitted in the body 3 at the top and bottom thereof, respectively. The interior of the body is at high discharge pressure.

An electric motor (electromotor, hereinafter referred to simply as “motor”) 6 is disposed inside the body 3, and a rotary shaft 12 is disposed inside the motor 6. Specifically, the motor 6 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com