Parting lathe tool

A technology of cutting tools and cutting blades, which is applied in the direction of tool holders, cutting blades, manufacturing tools, etc., and can solve the problems of cutting cutting tools flat, coolant restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

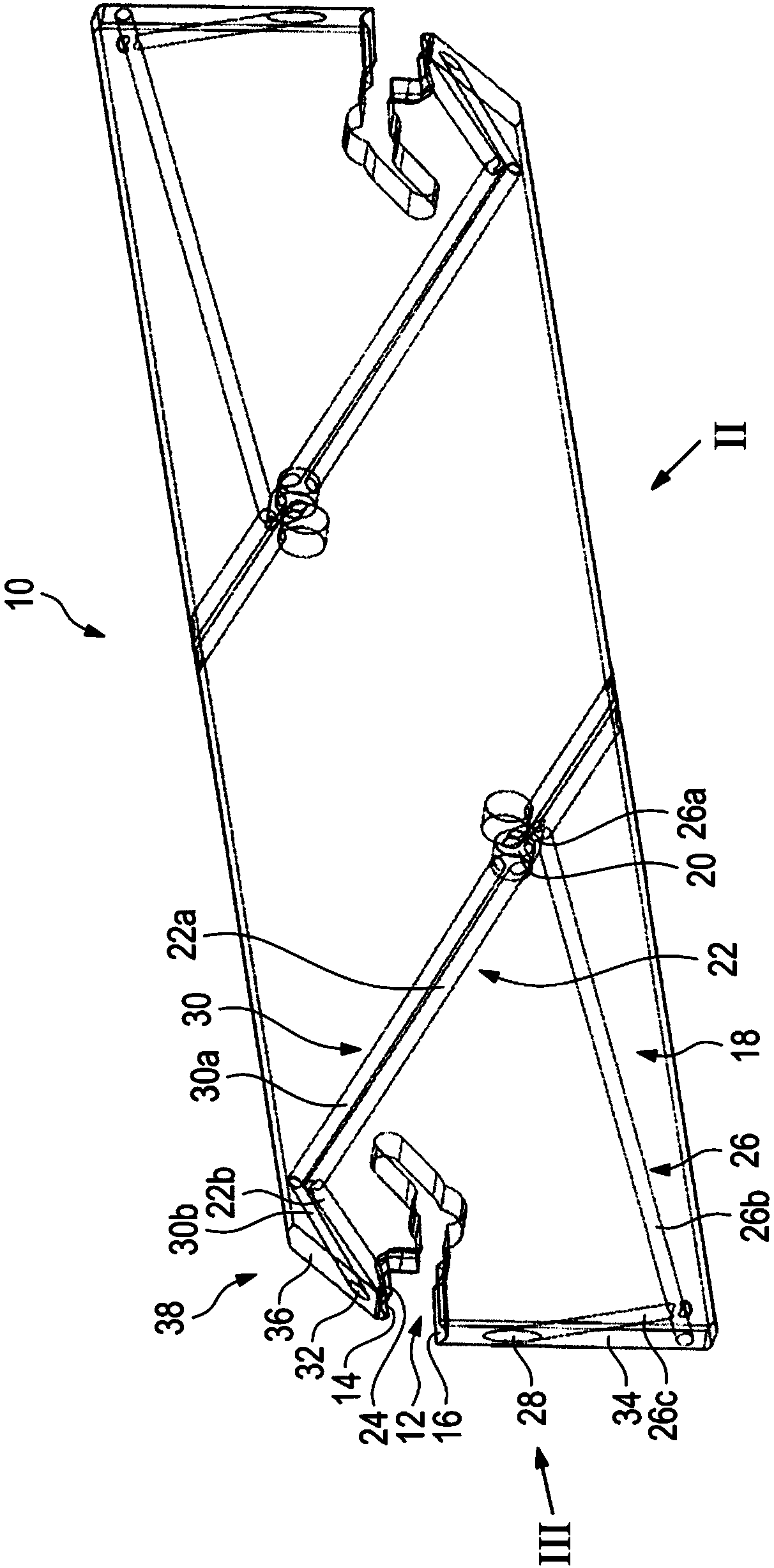

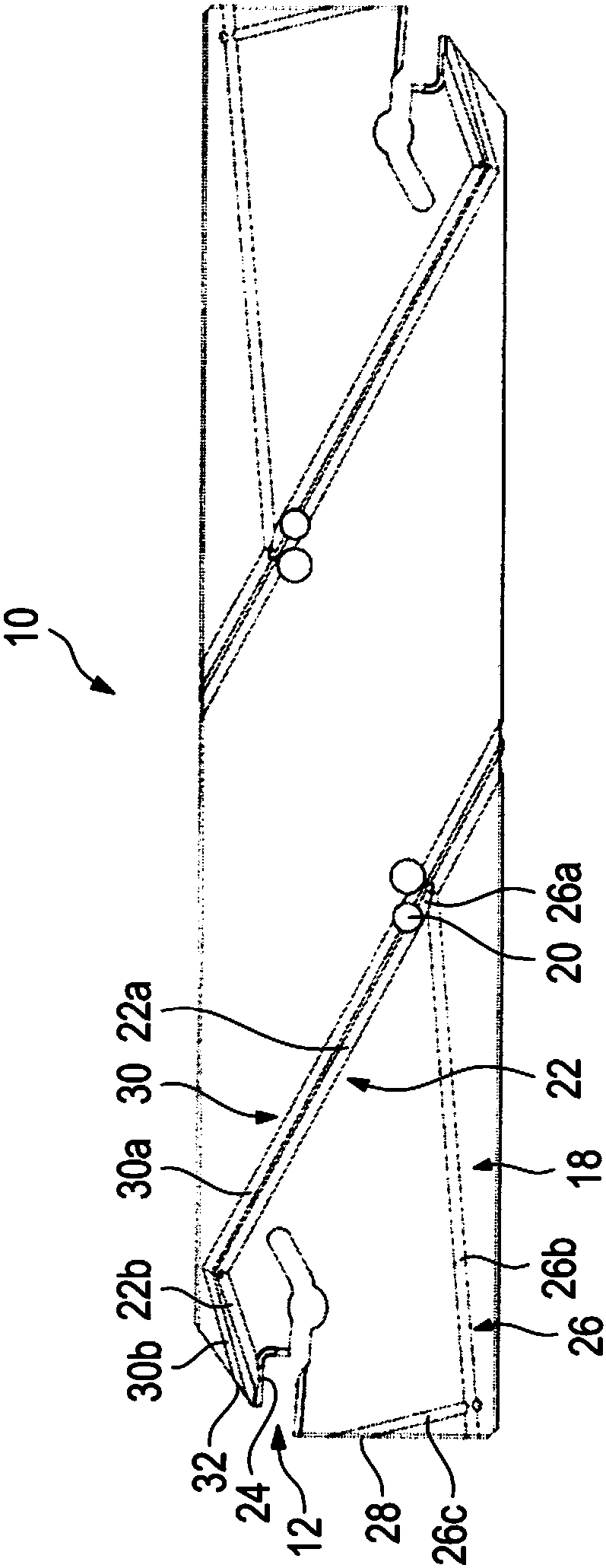

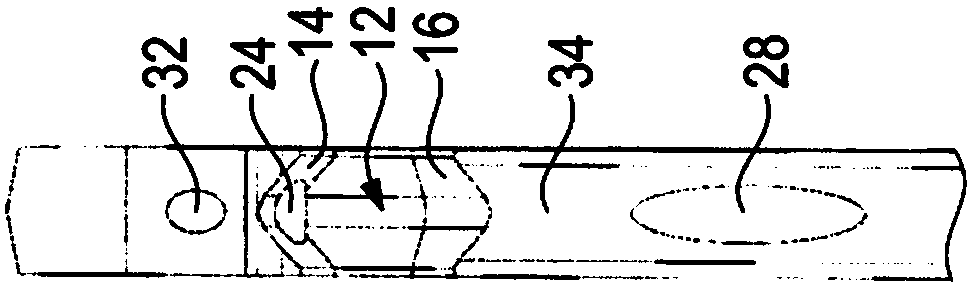

[0036] Figures 1 to 3 A parting off cutting tool 10 for cutting metal machining is shown.

[0037] The parting off cutting tool 10 may also be referred to as a parting off sword.

[0038] To accommodate cutting inserts, which are not shown in detail, which may in particular be indexable inserts, the parting-off cutting tool 10 comprises a clamping seat 12 . The clamping seat is essentially formed by two clamping surfaces 14 , 16 between which the cutting insert can be clamped.

[0039] The parting off cutting tool 10 also includes an internal coolant supply system 18 for supplying coolant to the cutting zone.

[0040] A coolant supply opening 20 is provided for this purpose on the parting-off cutting tool 10 on the part of the tool holder or on the part of the lathe.

[0041] The coolant supply opening is embodied as a substantially circular perforation and can be fluidically connected to a coolant supply outside the cut-off cutting tool 10 .

[0042] The parting off cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com