Waste gas absorption treatment device for casting production

A technology of treatment device and waste gas, applied in gas treatment, dispersed particle filtration, membrane technology, etc., can solve the problems of operator's health hazards, air pollution, large physical strength, etc., achieve full and thorough absorption, promote absorption, and increase utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

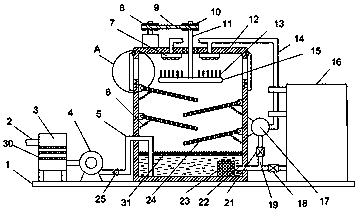

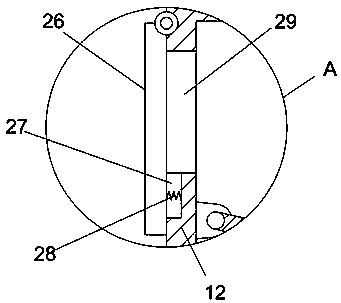

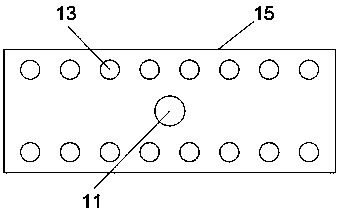

[0021] see Figure 1-3 , a waste gas absorption treatment device for casting production, comprising a bearing plate 1, an absorption box 12 is fixedly installed on the bearing plate 1, a driving motor is fixedly installed on the top of the absorption box 12, and the output shaft of the driving motor is fixedly installed coaxially There is a driving pulley 8, and the rotating shaft 11 is vertically arranged in the absorption box 12; the surface of the rotating shaft 11 is sleeved and fixedly installed with a driven pulley 10. The flat belt 9 is sleeved and connected; the lower end of the rotating shaft 11 is horizontally fixed with a rotating plate 15, and the upper surface of the rotating plate 15 is uniformly fixed with several vertically arranged dispersion rods 13, and the right side wall of the absorption box 12 is fixed. A water pump 17 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com