Slice sampling method used for determining recycled concrete carbonization zone microstructure

A technology of recycled concrete and carbonized area, which is applied in sampling, sampling device, preparation of test samples, etc., can solve the problem of differentiating sampling of old and new mortar, and achieve the effect of ensuring representativeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A slice sampling method for determining the phase composition of the carbonation zone of recycled concrete, comprising the following steps:

[0037] (1) Forming C30 recycled concrete specimens, wherein the recycled aggregate is obtained by crushing C20 primary concrete (mixed with 0.5% iron oxide red) prepared in the laboratory, and the replacement rate of recycled aggregate is 100%. ℃, relative humidity 70%, CO 2 Carbonization for 28 days in an environment with a concentration of 20%;

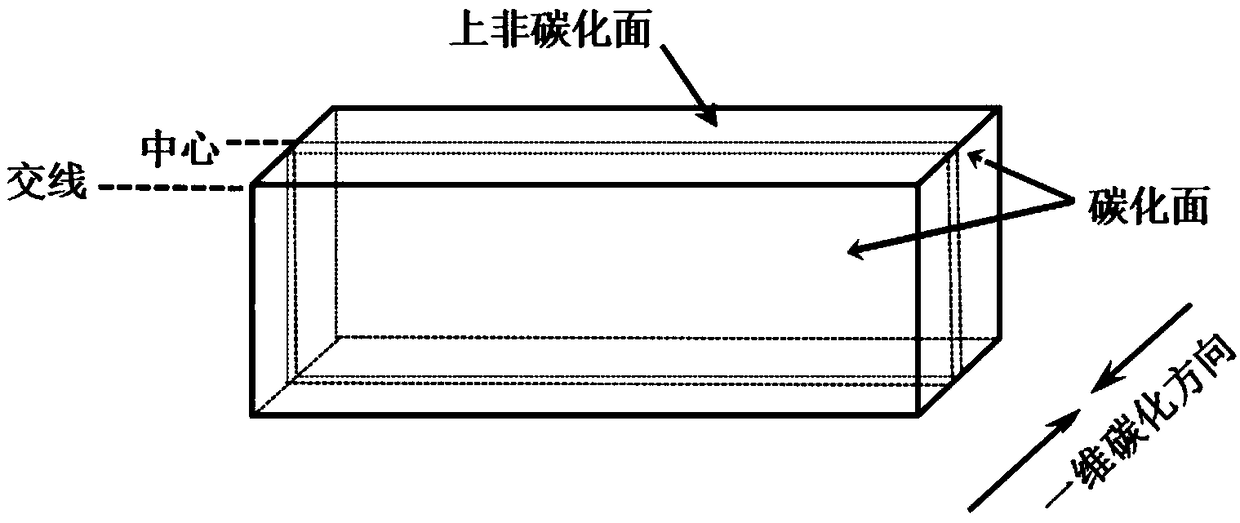

[0038] (2) slice: such as figure 1 , along the one-dimensional carbonization direction, from the intersection point of the front carbonization surface and the upper non-carbonization surface to the center of the concrete at an interval of 5mm vertical slices;

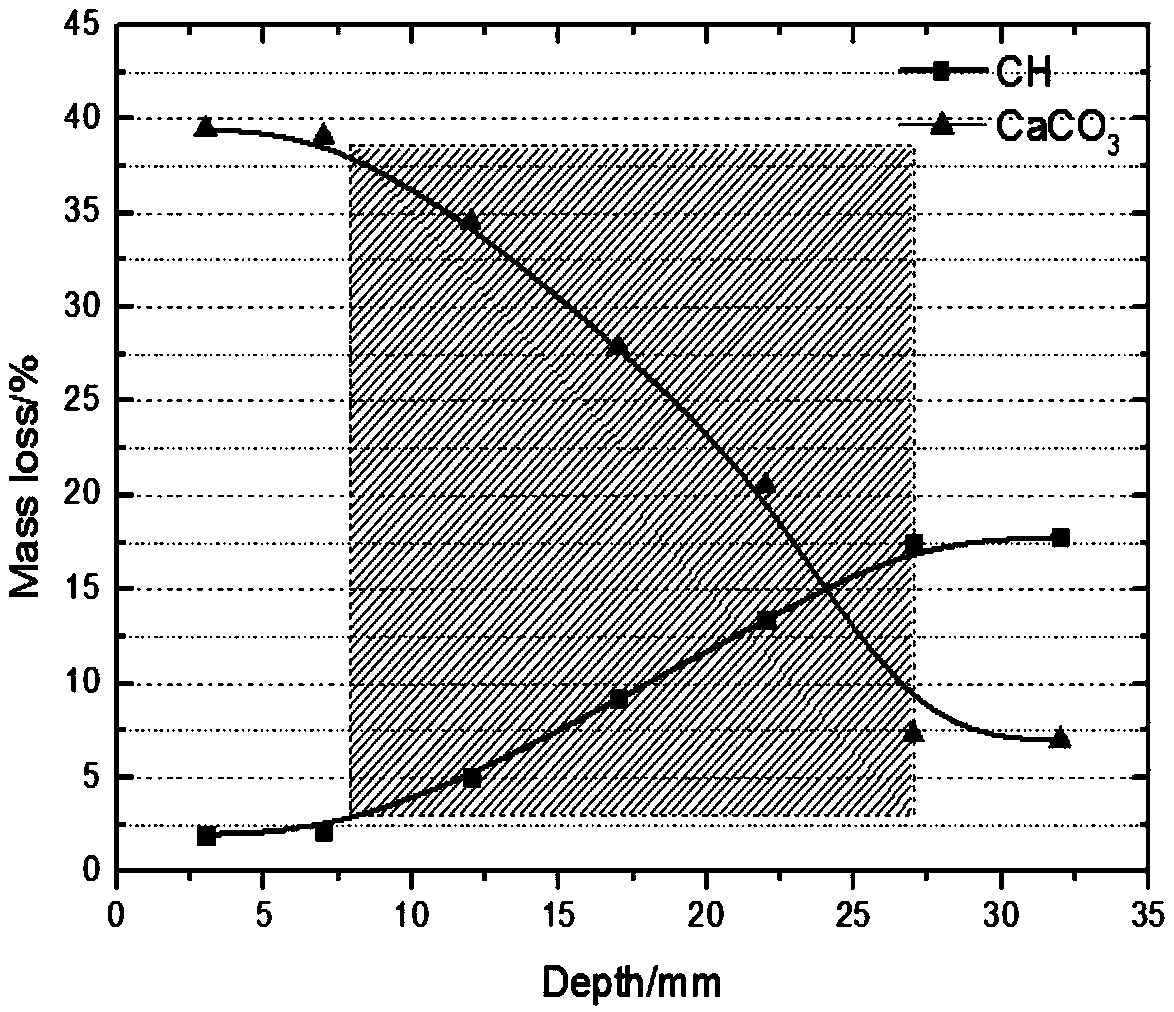

[0039](3) Sampling: The sampling locations are 0-5mm, 5-10mm, 10-15mm, 15-20mm, 20-25mm, 25-30mm, 30-35mm. Knock out the new mortar particles in this area with a small hammer, and after further crushing, put them into a mortar...

Embodiment 2

[0041] A slice sampling method for determining the phase composition of the carbonation zone of recycled concrete, comprising the following steps:

[0042] (1) Forming C30 recycled concrete specimens, wherein the recycled aggregate is obtained by crushing C20 primary concrete (mixed with 0.5% iron oxide red) prepared in the laboratory, and the replacement rate of recycled aggregate is 100%. ℃, relative humidity 70%, CO 2 Carbonization for 28 days in an environment with a concentration of 20%;

[0043] (2) slice: such as figure 1 , along the one-dimensional carbonization direction, from the intersection point of the front carbonization surface and the upper non-carbonization surface to the center of the concrete at an interval of 5mm vertical slices;

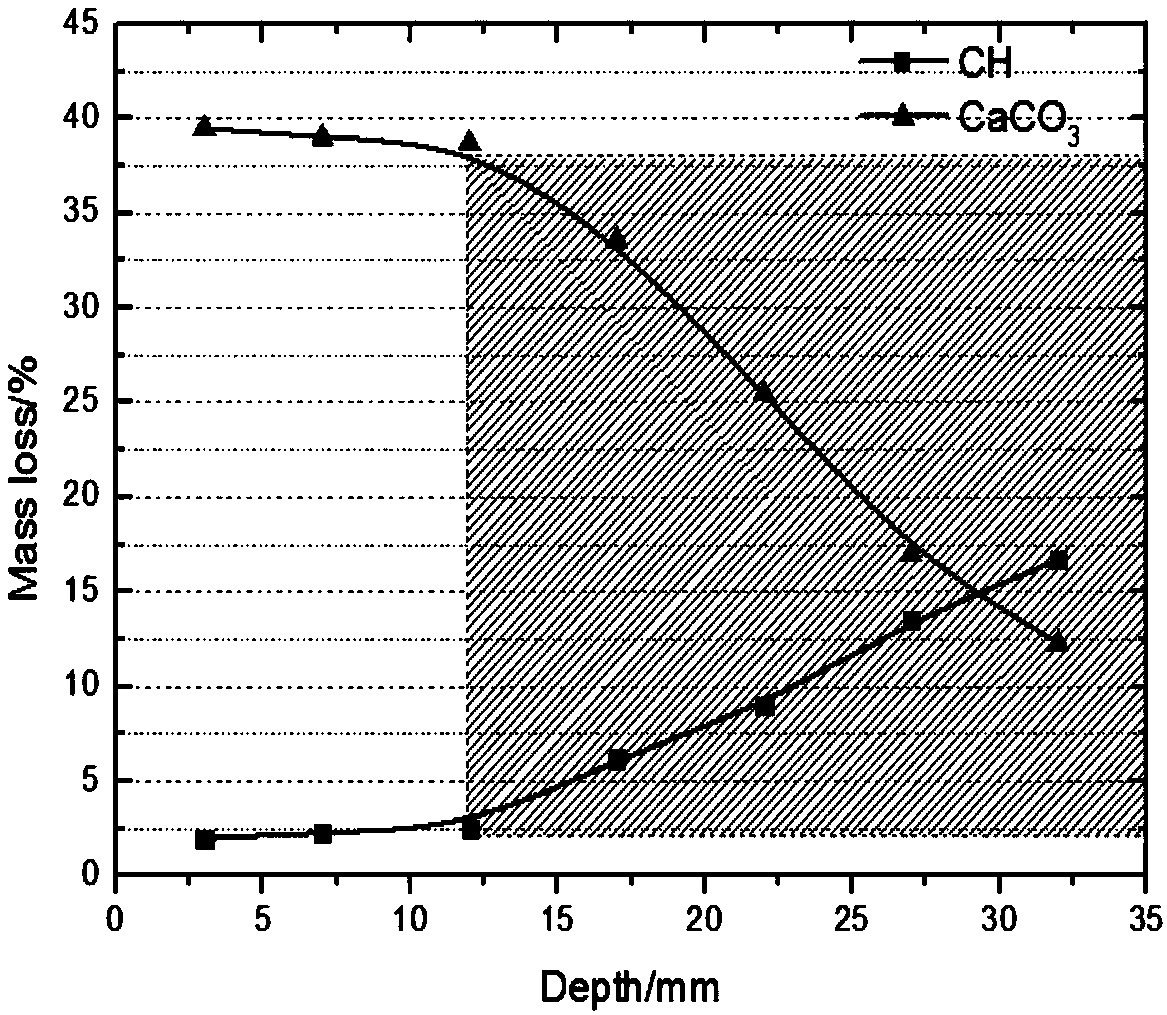

[0044] (3) Sampling: The sampling locations are 0-5mm, 5-10mm, 10-15mm, 15-20mm, 20-25mm, 25-30mm, 30-35mm. Knock out the old mortar particles in this area with a small hammer, and after further crushing, put them into a morta...

Embodiment 3

[0046] A slice sampling method for determining the phase composition of the carbonation zone of recycled concrete, comprising the following steps:

[0047] (1) Forming C30 recycled concrete specimens, wherein the recycled aggregate is obtained by crushing C20 primary concrete (mixed with 0.5% iron oxide red) prepared in the laboratory, and the replacement rate of recycled aggregate is 70%. ℃, relative humidity 70%, CO 2 Carbonization for 28 days in an environment with a concentration of 20%;

[0048] (2) slice: such as figure 1 , along the one-dimensional carbonization direction, from the intersection point of the front carbonization surface and the upper non-carbonization surface to the center of the concrete at an interval of 5mm vertical slices;

[0049] (3) Sampling: The sampling locations are 0-5mm, 5-10mm, 10-15mm, 15-20mm, 20-25mm, 25-30mm, 30-35mm. Knock out the new mortar particles in this area with a small hammer, and after further crushing, put them into a mortar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com