Method for manufacturing steelmaking converter steel slag deoxidization balls

A technology of steelmaking converter and manufacturing method, applied in the direction of manufacturing converters, etc., can solve the problems of difficult foaming slag, serious, deoxidizing addition of coke powder, etc., and achieve the goal of inhibiting the tendency of foaming slag, inhibiting the generation of foaming slag, and ensuring smooth discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for manufacturing steelmaking converter steel slag deoxidation balls, comprising the following steps:

[0025] Step (1) Select coke powder with a particle size of 1-3mm and fluorite powder with a particle size of 1-5mm and a calcium fluoride mass content of less than 70% as raw materials, and select water glass with a water content of 50% as a binder;

[0026] Step (2) Use coke powder, fluorite powder and water glass as raw materials, using a mass percentage of 78 : 20 : 2, use a ball press to press into a finished product with a diameter of 15mm, with a strength of 800N, and dry it naturally before use .

[0027] Load the deoxidation balls into the designated silo through the feeding belt. After reaching the silo, the powder rate is required to be less than 5%; the timing of adding the steelmaking slag deoxidation balls is selected: when the converter smelting is completed, the gun is lifted according to the expected end-point carbon content. The weighing sys...

Embodiment 2

[0029] A method for manufacturing steelmaking converter steel slag deoxidation balls, comprising the following steps:

[0030] Step (1) Select coke powder with a particle size of 1-3mm and fluorite powder with a particle size of 1-5mm and a calcium fluoride mass content of less than 65% as raw materials, and select water glass with a water content of 50% as a binder;

[0031] Step (2) Use coke powder, fluorite powder and water glass as raw materials, using a mass percentage of 72:25 : 3, use a ball press to press into a finished product with a diameter of 20mm, with a strength of 850N, and dry it naturally for use .

[0032] Load the deoxidation balls into the designated silo through the feeding belt. After reaching the silo, the powder rate is required to be less than 5%; the timing of adding the steelmaking slag deoxidation balls is selected: when the converter smelting is completed, the gun is lifted according to the expected end-point carbon content. The weighing system p...

Embodiment 3

[0034] (1) Production of steelmaking slag deoxidation balls

[0035] Coke powder, fluorite powder and binder are used as raw materials, according to a certain quality ratio, when the fluorite grade decreases, the fluorite ratio is appropriately increased. Use mixing equipment to mix, press into a finished product with a diameter of 18mm through a ball press, and dry naturally for use.

[0036] (2) Selection of timing for adding steelmaking slag deoxidation balls

[0037] At the end of converter smelting, when the torch is lifted, according to the expected end-point carbon content, the deoxidation balls are prepared in place through the weighing system of the blanking material, and added before the furnace is turned down.

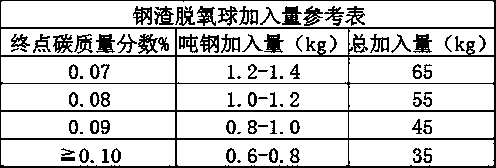

[0038] (3) The addition amount of steelmaking steel slag deoxidation balls should be selected as shown in Table 1. The addition amount should be selected according to the predicted carbon when the converter is lifted. The effects of increasing the melting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com