Waste butyl rubber regeneration technology and preparation method thereof

A technology for waste butyl rubber and waste butyl rubber, applied in the rubber field, can solve the problems of difficult realization of general experimental conditions, unfavorable environmental protection, waste of energy environment, etc. chain, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

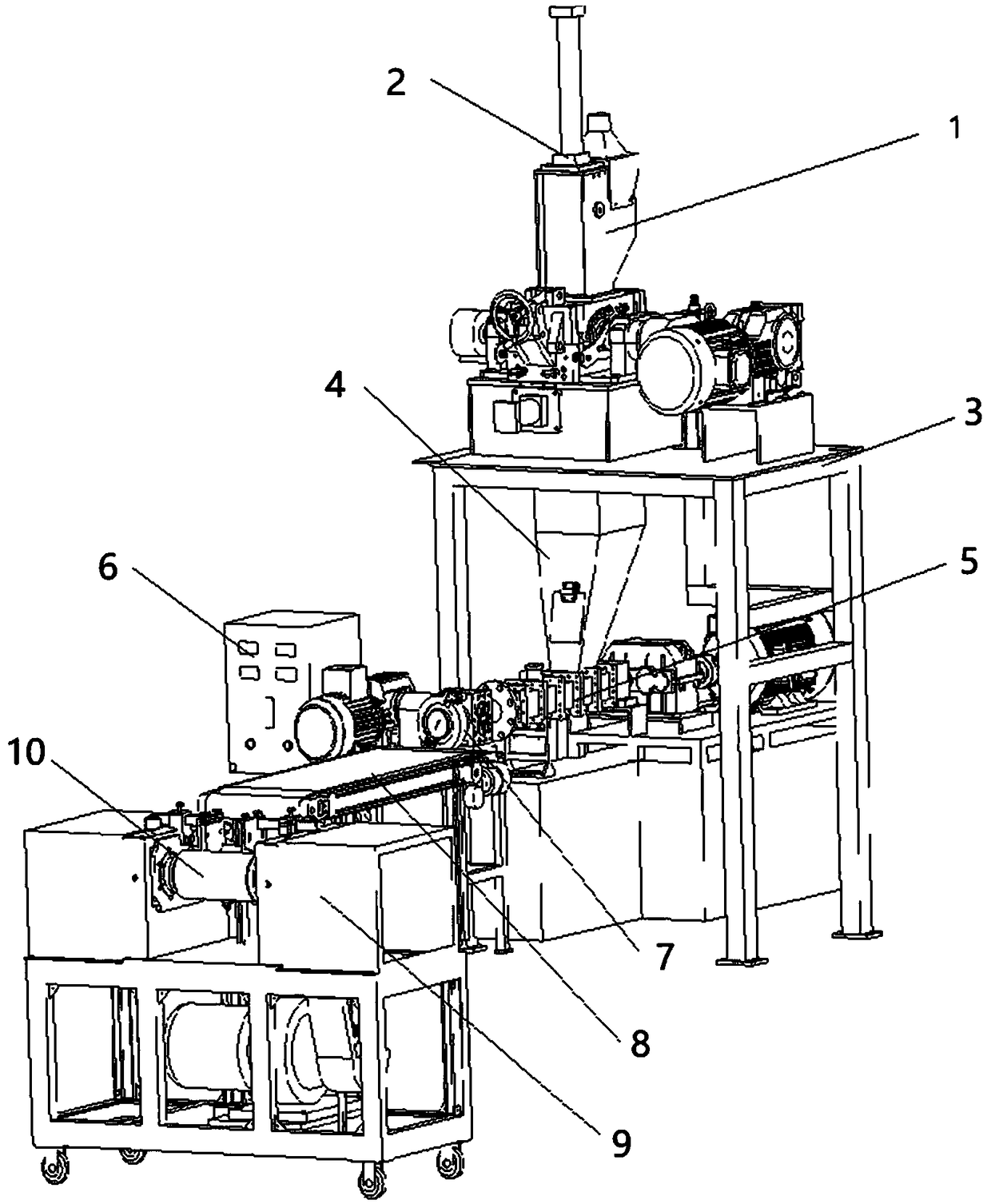

Image

Examples

Embodiment 1

[0056] Embodiment 1 A kind of waste butyl rubber regeneration process and preparation method thereof

[0057] Components: By weight fraction: 100 parts of waste butyl rubber, 2 parts of orange peel oil, 2 parts of anisoic acid, 3 parts of naphthalene sulfonate, 2 parts of special activator 580, 4 parts of paraffin oil, anti-aging agent RD1.8 share.

[0058] Preparation:

[0059] (1) First, after cleaning and drying the waste butyl rubber, cut it into small pieces of 50mm×50mm×5mm, and then mix it with orange peel oil, anisoic acid, naphthalene sulfonate, paraffin oil, and anti-aging agent RD according to the formula content Put it into the internal mixer, and adjust the filling factor to 0.7, the pressure of the upper top bolt to 0.5Mpa, the temperature to 65°C, the control speed to be 50r / min, press down the top bolt to carry out internal mixing for 1min, and then lift the bolt to add the component content The special effect activator 580 is pressed on the top bolt and then...

Embodiment 2

[0065] Embodiment 2 A kind of waste butyl rubber regeneration process and its preparation method

[0066] Components: by weight fraction: 100 parts of waste butyl rubber, 2.2 parts of lemon peel oil, 2.2 parts of terpinene, 3.2 parts of naphthalene sulfonate, 2.2 parts of special effect activator 580, 4.2 parts of paraffin oil, anti-aging agent RD1. 8 servings.

[0067] Preparation:

[0068] (1) First, after cleaning and drying the waste butyl rubber, cut it into small pieces of 20mm×20mm×5mm, and then mix it with lemon peel oil, terpinene, naphthalene sulfonate, paraffin oil and anti-aging agent according to the formula content Put RD into the internal mixer, and adjust the filling factor to 1.05, the pressure of the top bolt is 0.5Mpa, the temperature is 65°C, the speed is controlled at 60r / min, and the top bolt is pressed down for internal mixing for 1min, and then the bolt is lifted to add the components The specific effect activator of content 580 is pressed on top bolt...

Embodiment 3

[0074] Embodiment 3 A kind of waste butyl rubber regeneration process and its preparation method

[0075] Components: by weight fraction: 100 parts of waste butyl rubber, 2 parts of lemon peel oil, 2 parts of terpinene, 3 parts of naphthalene sulfonate, 2 parts of special activator 580, 4 parts of paraffin oil, 0.1 part of lignin , anti-aging agent RD1.8 parts.

[0076] Preparation method: same as Example 1.

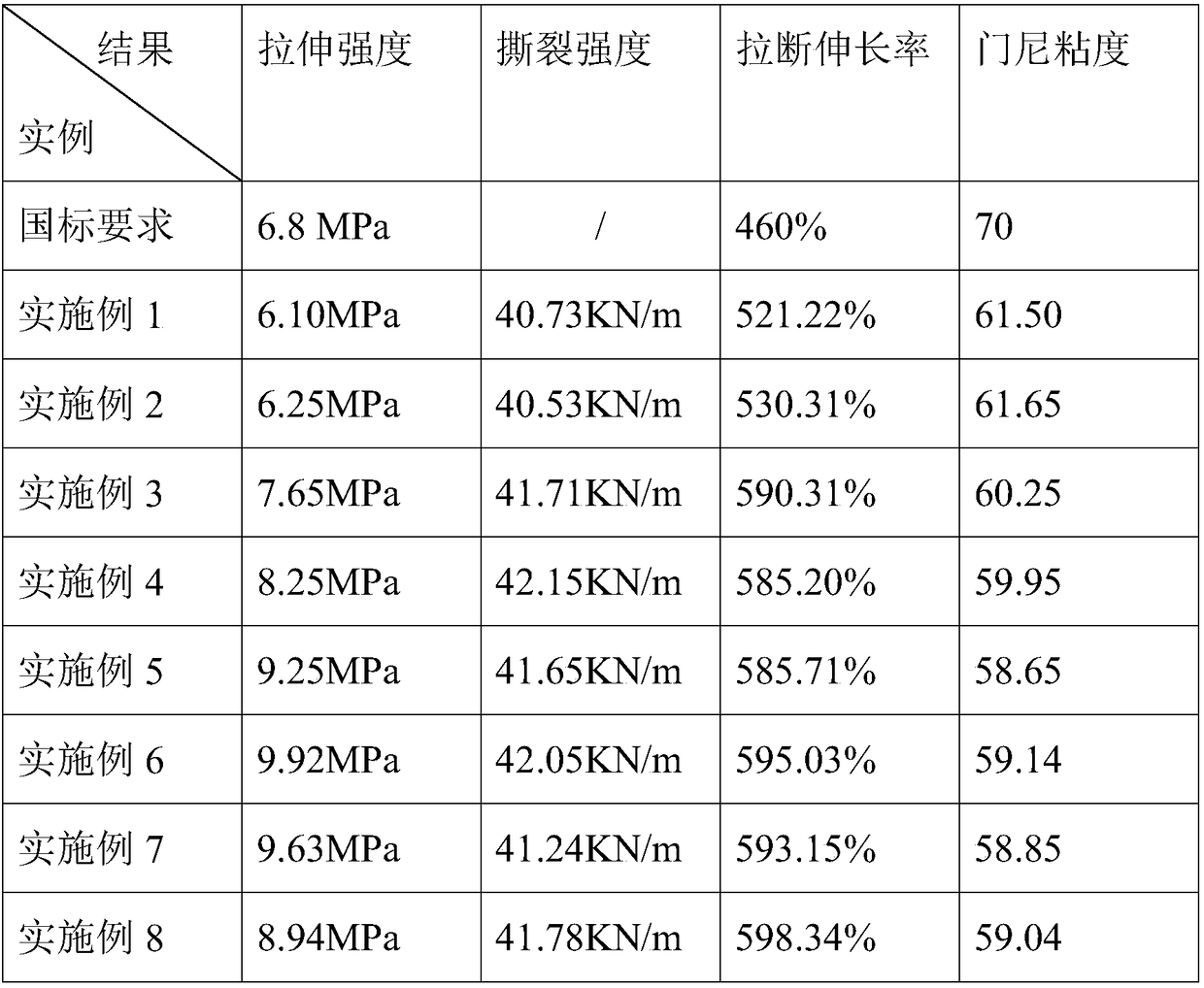

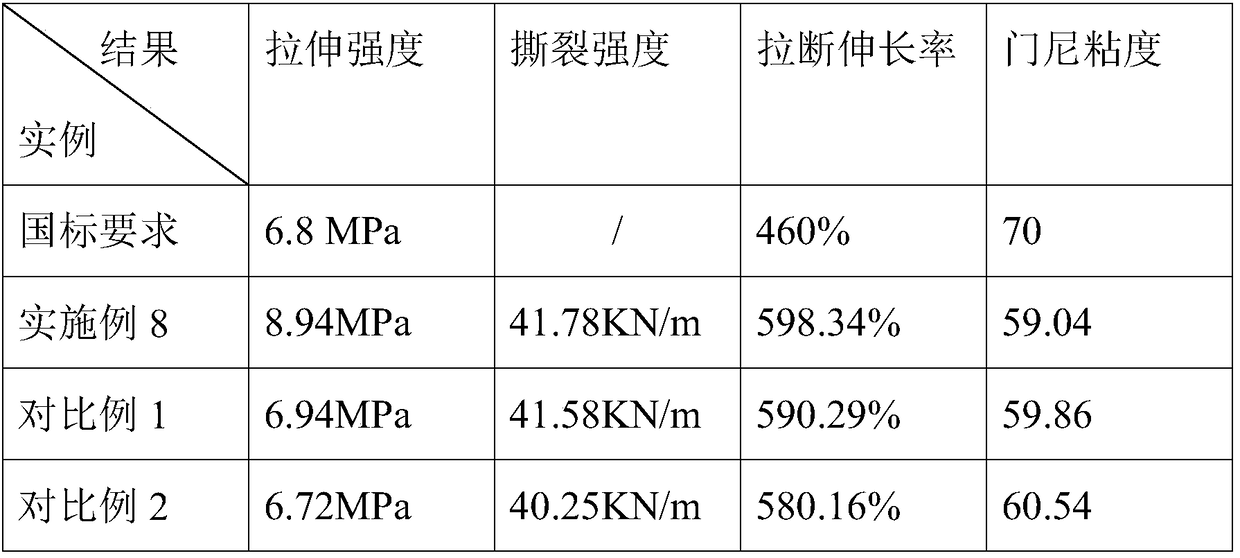

[0077] Its properties are as follows: tensile strength 7.65MPa, tear strength 41.71KN / m, elongation at break 590.31%. , Mooney viscosity 60.25.

[0078] The performance of recycled butyl rubber in the national standard GB / T 13460-2016 general specification for recycled rubber: tensile strength 6.8MPa, elongation at break 460%, Mooney viscosity 70.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com