Ultrafine ammonium paratungstate evaporative crystallization device and crystallization method

An evaporative crystallization and ammonium paratungstate technology, which is applied in the directions of evaporative separation crystallization, evaporation, solution crystallization, etc., can solve the problems of unutilized steam heat energy, energy waste, and coarse evaporative crystallization crystals, so as to improve heat energy, reduce production energy consumption, improve The effect of the warm-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

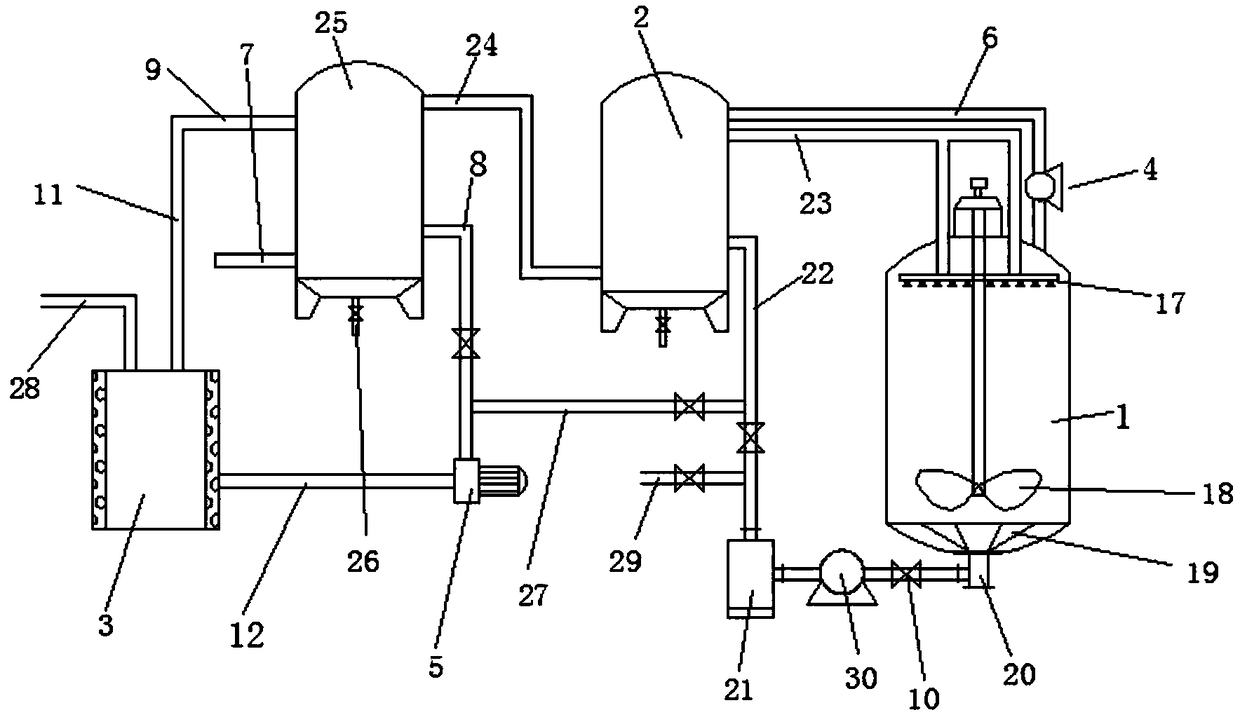

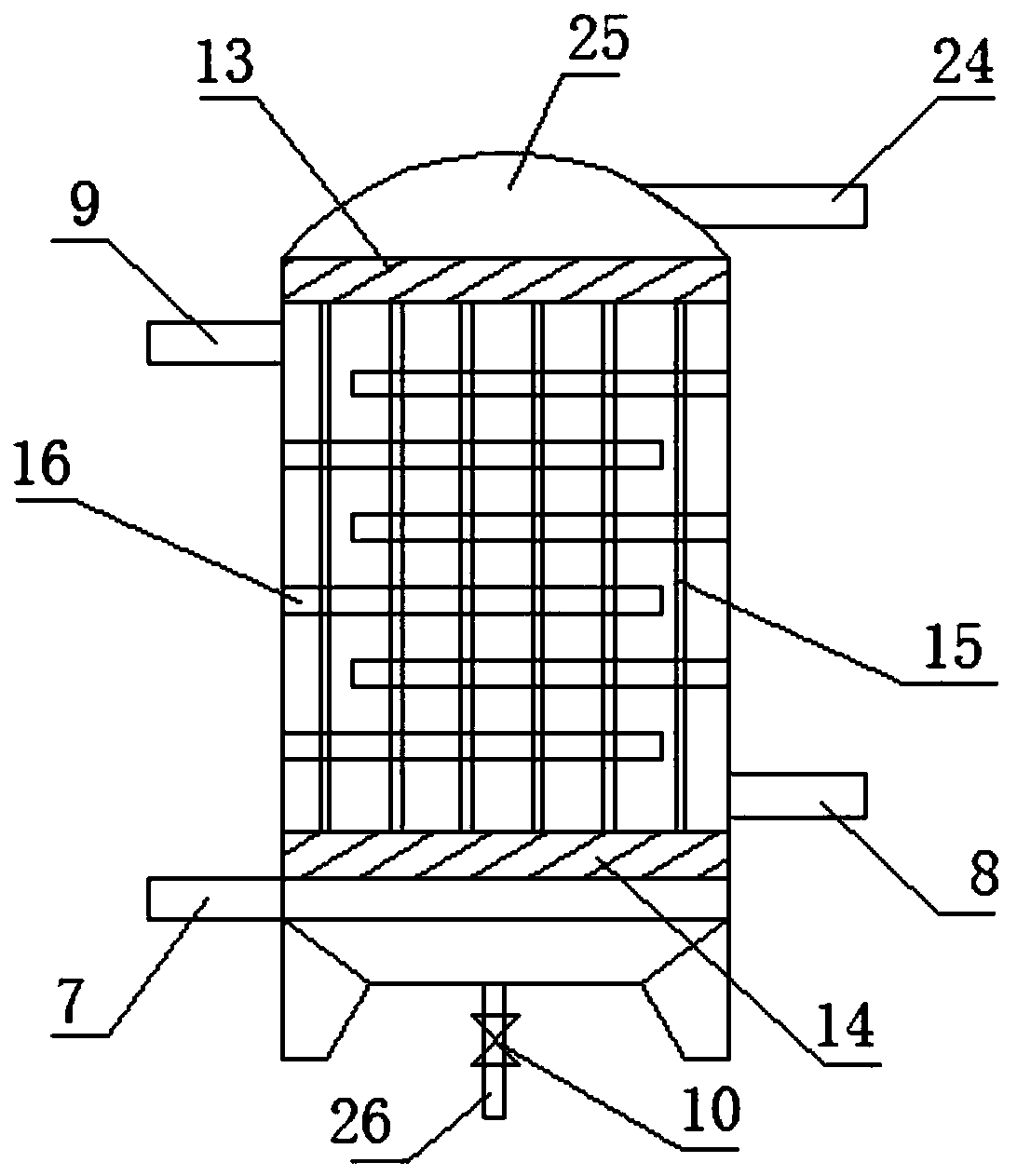

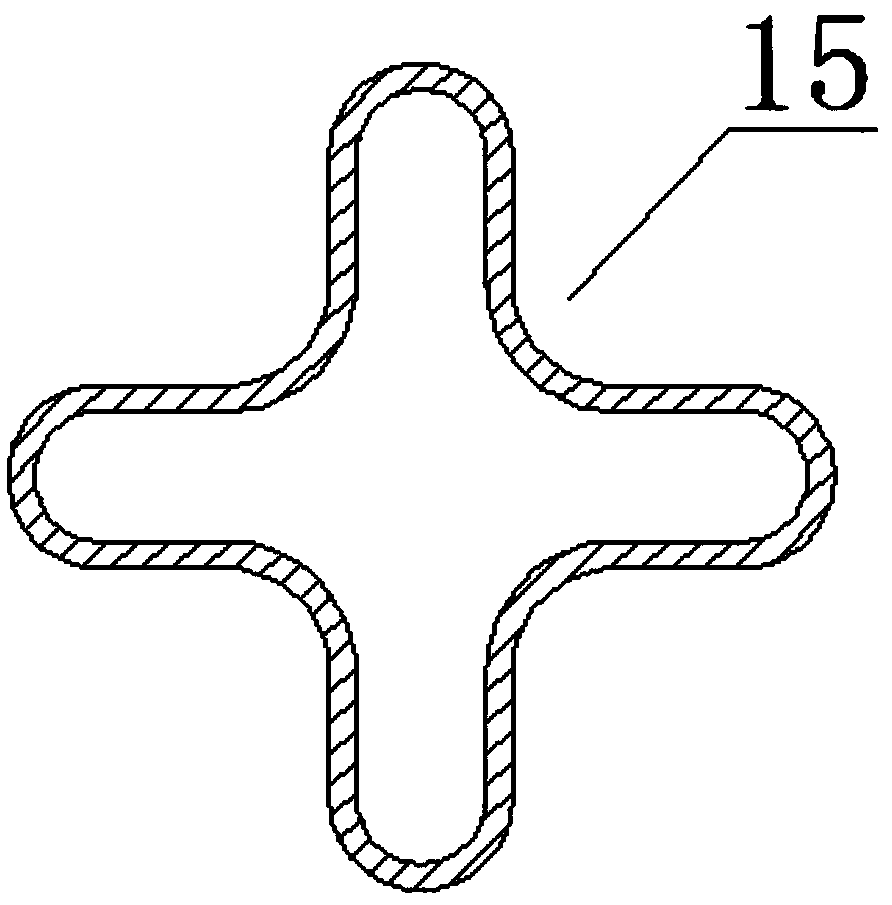

[0033] Such as figure 1 and figure 2As shown, the ultrafine ammonium paratungstate evaporative crystallization device of the present invention includes an evaporative crystallization kettle 1, a first heat exchanger 2, a second heat exchanger 25 and an ammonium tungstate insulation circulation tank 3 from left to right or from right to left, A first steam pipe 6 and a filtered liquid return pipe 23 are connected between the upper part of the evaporation crystallization kettle 1 and the first heat exchanger 2, a compressor 4 is arranged on the first steam pipeline 6, and a stirring paddle is arranged in the middle of the evaporation crystallization kettle 1 18. There is a flow deflector 19 and a discharge port 20 at the bottom, and a spray device 17 at the top, and the spray device 17 is connected to the filtered liquid return pipe 23; there is a filter press 21 at the bottom of the first heat exchanger 2. The machine 21 is connected to the slurry pump 30 through a pipeline, ...

Embodiment 2

[0047] During the evaporation and crystallization process, the slurry is drawn out from the discharge port at the bottom of the evaporation crystallization kettle, and the ultrafine ammonium paratungstate just formed is trapped in the filter press through the diaphragm filter press. The purpose of filtering is to prevent APT crystals from growing up in the kettle. The usual practice is to filter APT after the evaporation and crystallization is completed, and the obtained filtrate ammonium tungstate solution is atomized through a centrifugal nozzle under negative pressure (small droplets, fast evaporation) and then enters the evaporation crystallization kettle for evaporation and crystallization. Control the stirring speed of evaporation and crystallization to 500-1000 rpm (high-speed stirring, first, it can accelerate the turnover of the liquid surface, increase the evaporation area, and facilitate the rapid precipitation of crystal nuclei; second, the growth of APT crystals is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com