Device and method for recovery of waste heat from medium-and-high-temperature solid powder

A waste heat recovery device, medium and high temperature technology, applied in heat exchanger types, lighting and heating equipment, direct contact heat exchangers, etc., can solve the problems of wasting water resources, complex structure, air pollution, etc. Simple structure of pipes and devices, and the effect of improving heat exchange rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

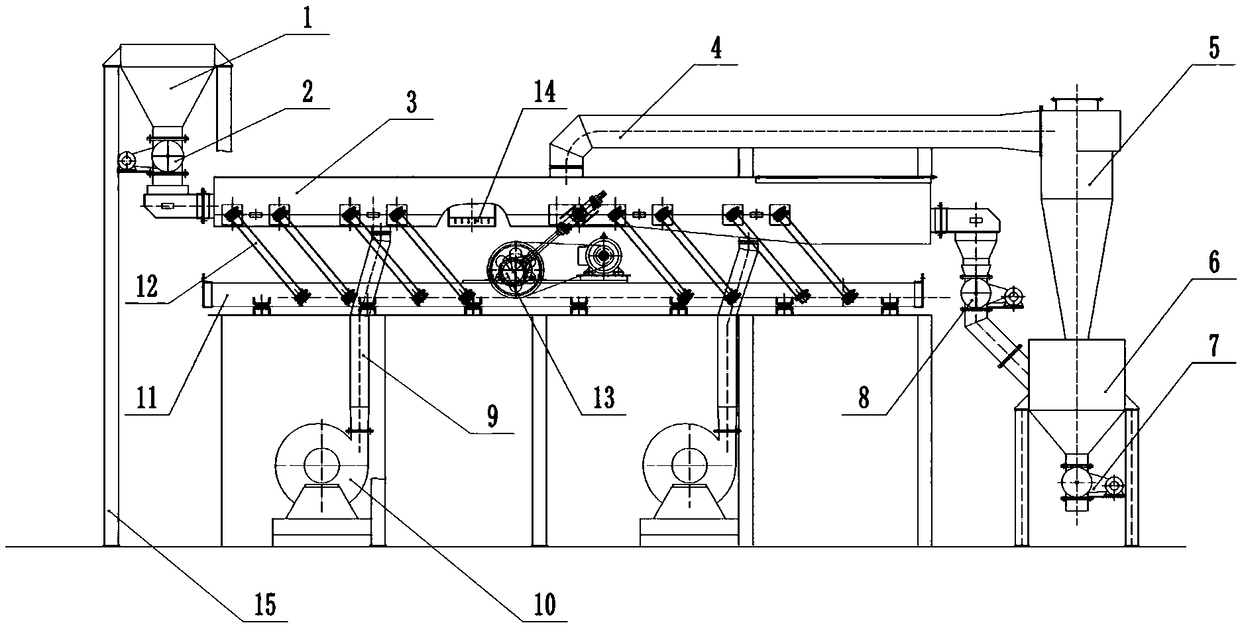

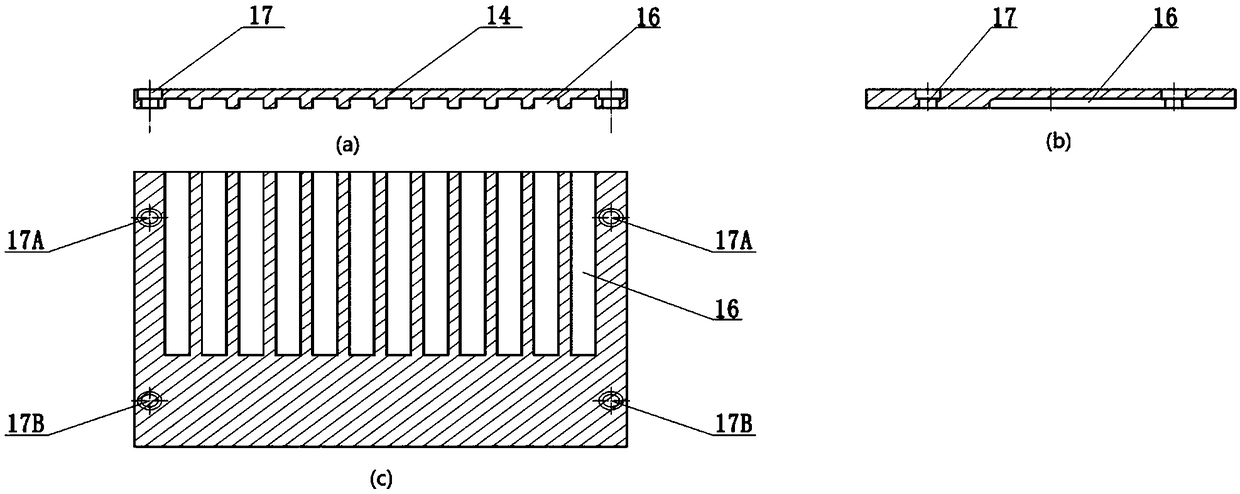

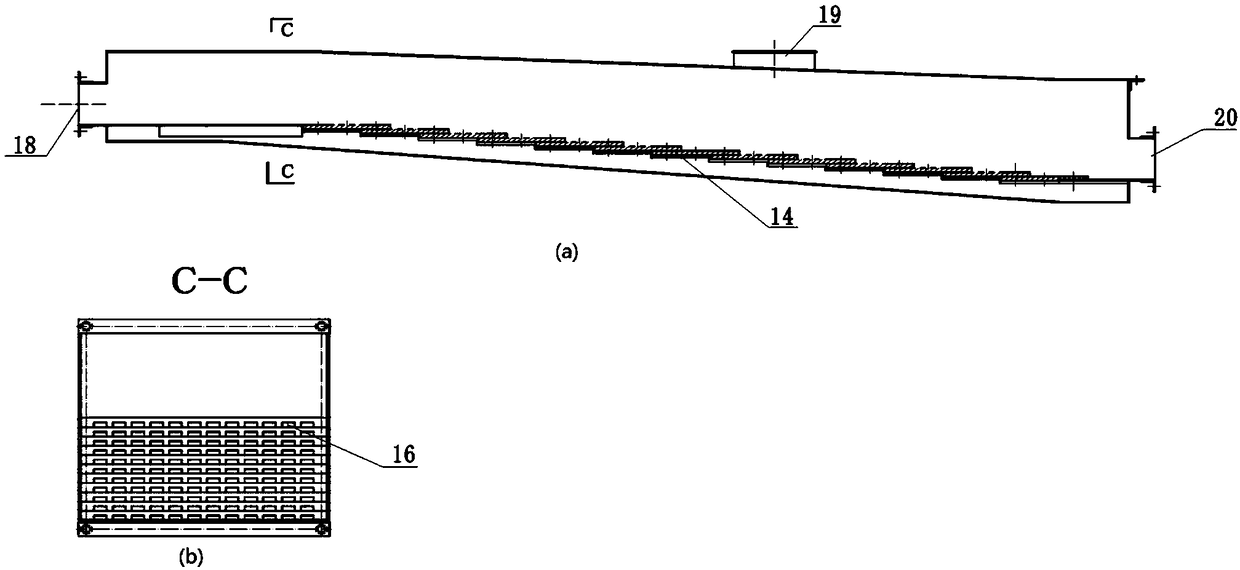

[0031] Such as figure 1 As shown, a medium-high temperature solid powder waste heat recovery device includes a hopper 1, a rotary seal discharge valve 2, a vibration waste heat recovery device 3, a hot air pipeline 4, a cyclone dust collector 5, a storage tank 6, a rotary seal discharge valve Material valve 3 7, rotary sealing discharge valve 2 8, cold air pipeline 9, air blower 10, steel bracket 15; the bottom of hopper 1 is connected with the inlet of rotary sealing discharge valve 1 2 through flange bolts, and the connection is made of high temperature resistant stone Cotton cloth is used for sealing; the bottom of rotary sealing discharge valve 1 2 is softly connected with the entrance of vibration waste heat recovery device 3 through high temperature resistant asbestos; the vibration waste heat recovery device is composed of vibration frame 11, vibration motor 13, vibration spring 12 and air distribution plate 14, the outlet of which is also softly connected with the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com