590 MPa semi-cold hardened steel strip and cover furnace production process thereof

A cold work hardening and production process technology, applied in metal rolling and other directions, can solve the problems of low recrystallization temperature of steel strip substrate, difficult recovery process, high production cost, etc., and achieve low production cost, stable mechanical properties, and high production short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

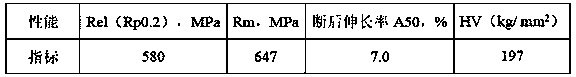

Embodiment 1

[0022] The composition of the steel strip in this embodiment is calculated by weight percentage, C: 0.0037%, Si: 0.03%, Mn: 0.17%, P: 0.0010%, S: 0.0020%; Als: 0.050%. The specific production process is as follows:

[0023] (1) Converter molten steel smelting: transfer the molten iron obtained from the blast furnace into the converter, the C content of the tapping is 0.072%, and it reaches 0.047% after tapping, the tapping temperature is 1660°C, no deoxidizer and alloy are added during the tapping process, and the whole process is blown argon;

[0024] (2) Refining of LF molten steel: transfer the molten steel obtained in the converter to the LF furnace for aluminum deoxidation, and determine the feeding amount of aluminum wire 571 meters according to the fixed oxygen value; the LF furnace does not carry out Ca treatment and does not add any alloy;

[0025] (3) RH molten steel refining: Control the RH arrival temperature at 1636°C; vacuum degassing and composition adjustment ...

Embodiment 2

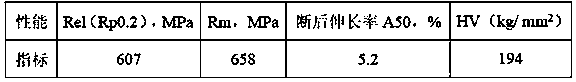

[0033] The composition of the steel strip in this embodiment is calculated by weight percentage, C: 0.0050%, Si: 0.027%, Mn: 0.3%, P: 0.0079%, S: 0.0042%; Als: 0.039%. The specific production process is as follows:

[0034] (1) Converter molten steel smelting: Transfer the molten iron obtained from the blast furnace into the converter, control the tapping C at 0.060%, and reach 0.045% after tapping, and the tapping temperature is 1684°C. No deoxidizer and alloy are added during the tapping process. argon blowing;

[0035] (2) Refining of LF molten steel: transfer the molten steel obtained in the converter to the LF furnace for aluminum deoxidation, and determine the feeding amount of the aluminum wire as 493 meters according to the fixed oxygen value; the LF furnace does not carry out Ca treatment and does not add any alloy;

[0036] (3) RH molten steel refining: Control the RH arrival temperature at 1632°C; vacuum degassing and composition adjustment of the molten steel in t...

Embodiment 3

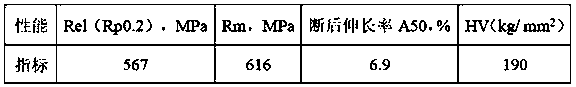

[0044] The composition of the steel strip in this embodiment is calculated by weight percentage, C: 0.0039%, Si: 0.05%, Mn: 0.23%, P: 0.0097%, S: 0.0019%; Als: 0.030%. The specific production process is as follows:

[0045] (1) Converter molten steel smelting: Transfer the molten iron obtained from the blast furnace into the converter. The C content in the tapping is 0.080%, and it reaches 0.055% after tapping. The tapping temperature is 1690°C. No deoxidizer and alloy are added during the tapping process. argon blowing;

[0046](2) Refining of LF molten steel: transfer the molten steel obtained in the converter to the LF furnace for aluminum deoxidation, and determine the feeding amount of aluminum wire 456 meters according to the fixed oxygen value; the LF furnace does not carry out Ca treatment and does not add any alloy;

[0047] (3) RH molten steel refining: the arrival temperature of RH is 1630℃; the molten steel is subjected to vacuum degassing and composition adjustme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com