Continuous production apparatus and method for glycerol

A production method and technology for glycerol, applied in chemical instruments and methods, separation/purification of hydroxyl compounds, organic chemistry, etc., can solve the problems of poor production efficiency, increased energy consumption, and high operating costs, and improve production efficiency and income. efficiency and product quality, reducing wastewater discharge, and reducing the amount of solid residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

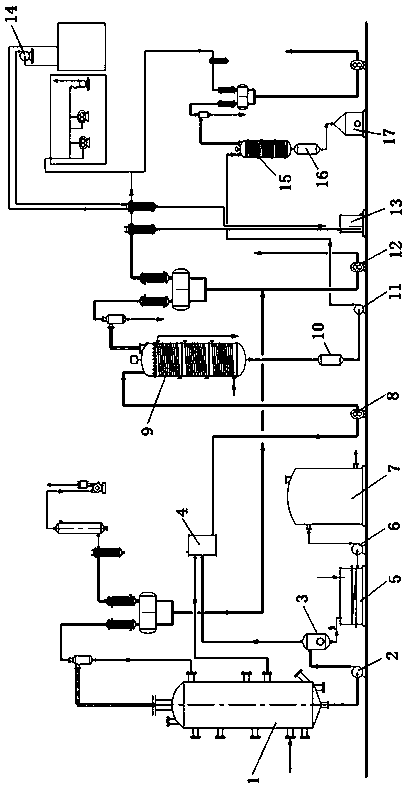

[0028] Embodiment 1: Continuously produce glycerin according to the following steps

[0029] (1) Turn on the distillation three-stage condensation vacuum system of the distillation pot to reach the ultimate vacuum of 3.0KPa, the liquid phase temperature is 180°C, and the vapor phase temperature is 152°C; the gas phase outlet temperature of the first condenser is 110°C; the gas phase outlet of the second condenser The temperature is 75°C; the gas phase outlet temperature of the third condenser is 50°C; the raw material crude glycerin with a mass content of 70% is preheated to 70°C and enters the still 1; The temporary receiver at the bottom of the second condenser collects refined glycerin, and the refined glycerin is pumped to the deodorizing tank and the decolorizing tank respectively to deodorize and decolorize to obtain No. 1 finished glycerin, which is filled; The crude glycerin delivery pump 2 is pumped into the desalting tank 3 to filter out the salt; the upper layer of ...

Embodiment 2

[0032] Embodiment 2: Continuously produce glycerin according to the following steps

[0033] (1) Turn on the distillation three-stage condensing vacuum system of the distillation pot to reach the ultimate vacuum of 4.5KPa, the liquid phase temperature is 185°C, and the vapor phase temperature is 156°C; the gas phase outlet temperature of the first condenser is 120°C, and the gas phase outlet of the second condenser The temperature is 80°C, and the gas phase outlet temperature of the third condenser is 40°C; the raw material crude glycerol with a mass content of 75% is preheated to 75°C and enters the still 1; The temporary receiver at the bottom of the second condenser collects refined glycerin, and the refined glycerin is pumped to the deodorizing tank and the decolorizing tank respectively to deodorize and decolorize to obtain No. 1 finished glycerin, which is filled; The crude glycerin delivery pump 2 is pumped into the desalting tank 3 to filter out the salt; the upper lay...

Embodiment 3

[0036] Embodiment 3: Continuously produce glycerol according to the following steps

[0037] (1) Turn on the distillation three-stage condensation vacuum system of the distillation pot to reach the ultimate vacuum of 6.0KPa, the liquid phase temperature is 195°C, the vapor phase temperature is 160°C, the gas phase outlet temperature of the first condenser is 135°C, and the gas phase outlet of the second condenser The temperature is 85°C, and the gas phase outlet temperature of the third condenser is 30°C; raw material crude glycerin with a mass content of 80% is preheated to 80°C and enters still 1; The temporary receiver at the bottom of the second condenser collects refined glycerin, and the refined glycerin is pumped to the deodorizing tank and the decolorizing tank respectively to deodorize and decolorize to obtain No. 1 finished glycerin, which is filled; The crude glycerin delivery pump 2 is pumped into the desalting tank 3 to filter out the salt; the upper layer of desa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com