Purification method and device for boron trichloride

A boron trichloride and purification method technology, applied in the direction of boron halide compounds, boron halides, etc., can solve the problems of high energy consumption and difficult purification, and achieve the effects of low energy consumption, improved purification effect, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

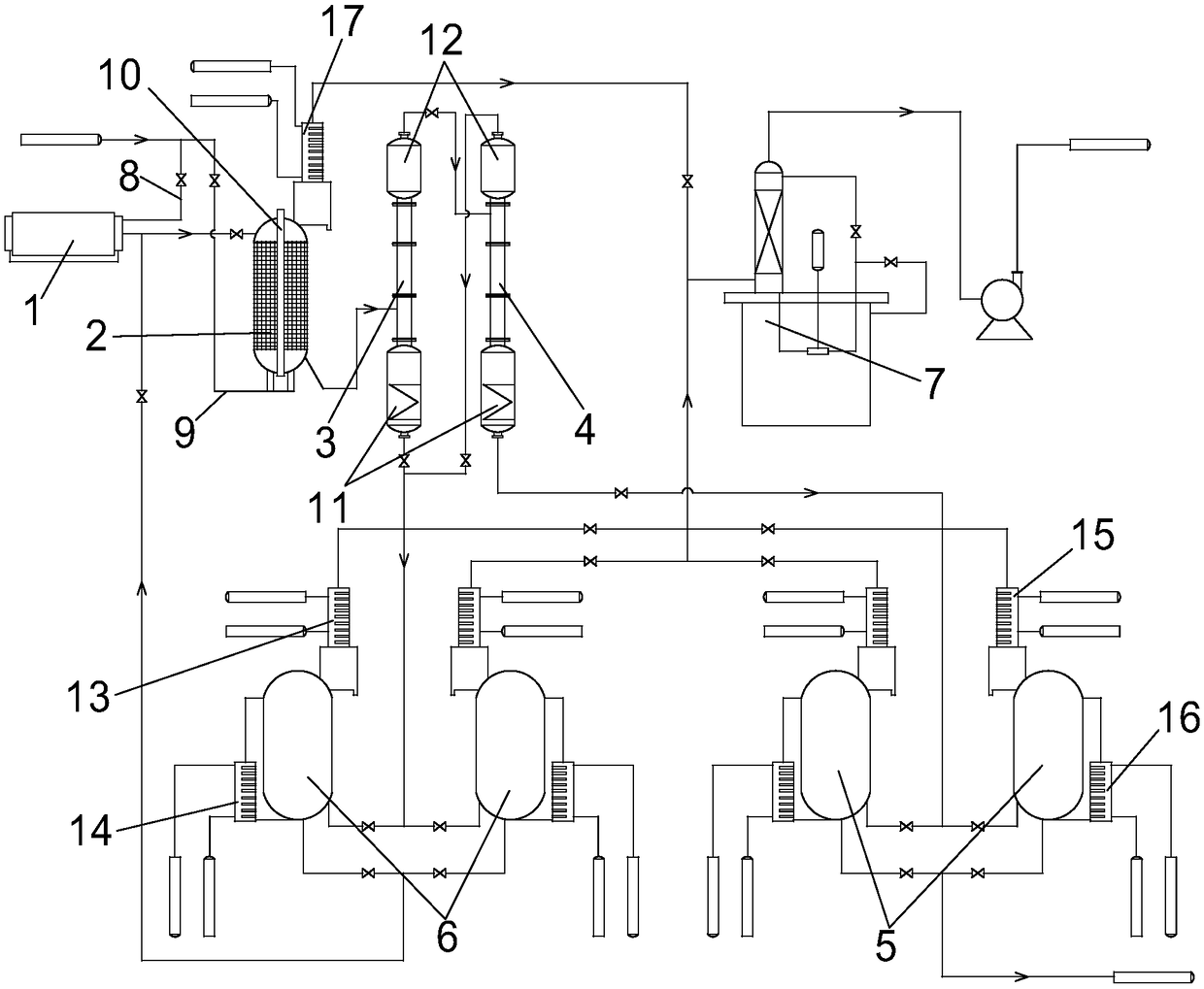

Image

Examples

Embodiment

[0018] A kind of purification method of boron trichloride, provides flowing power for the purification of boron trichloride solution by differential pressure, and its concrete method comprises the following steps:

[0019] S1 Decomposition Section: The raw material tank is pressurized to 5.5-6.5 bar with an inert gas, and then the crude boron trichloride liquid phase is extruded to the carbonyl chloride decomposer. Acyl chloride impurities are catalyzed by ultraviolet light to decompose (COCl 2 →CO↑+Cl 2 ↑), the reaction pressure in the carbonyl chloride decomposer is 4.5-5.5bar, and the reaction temperature is 30-40°C; while the impurities are being decomposed, the inert gas passes through the evenly distributed inert gas blowback holes at the bottom of the phosgene The carbon monoxide and chlorine gas produced by phosgene are backflushed to remove these impurities from the boron trichloride liquid and discharged from the top of the phosgene decomposer. The backflush pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com