Magnetic seed magnetization dry-separation process for extracting iron from sintering dust

A magnetic seed and dry separation technology, applied in the fields of magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of waste water treatment, water pollution, large water consumption, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The sintering dust removal ash that this implementation of the present invention adopts comes from Jiuquan Iron and Steel Sintering Plant, and the sintering dust removal ash of iron grade 32% is carried out following treatment:

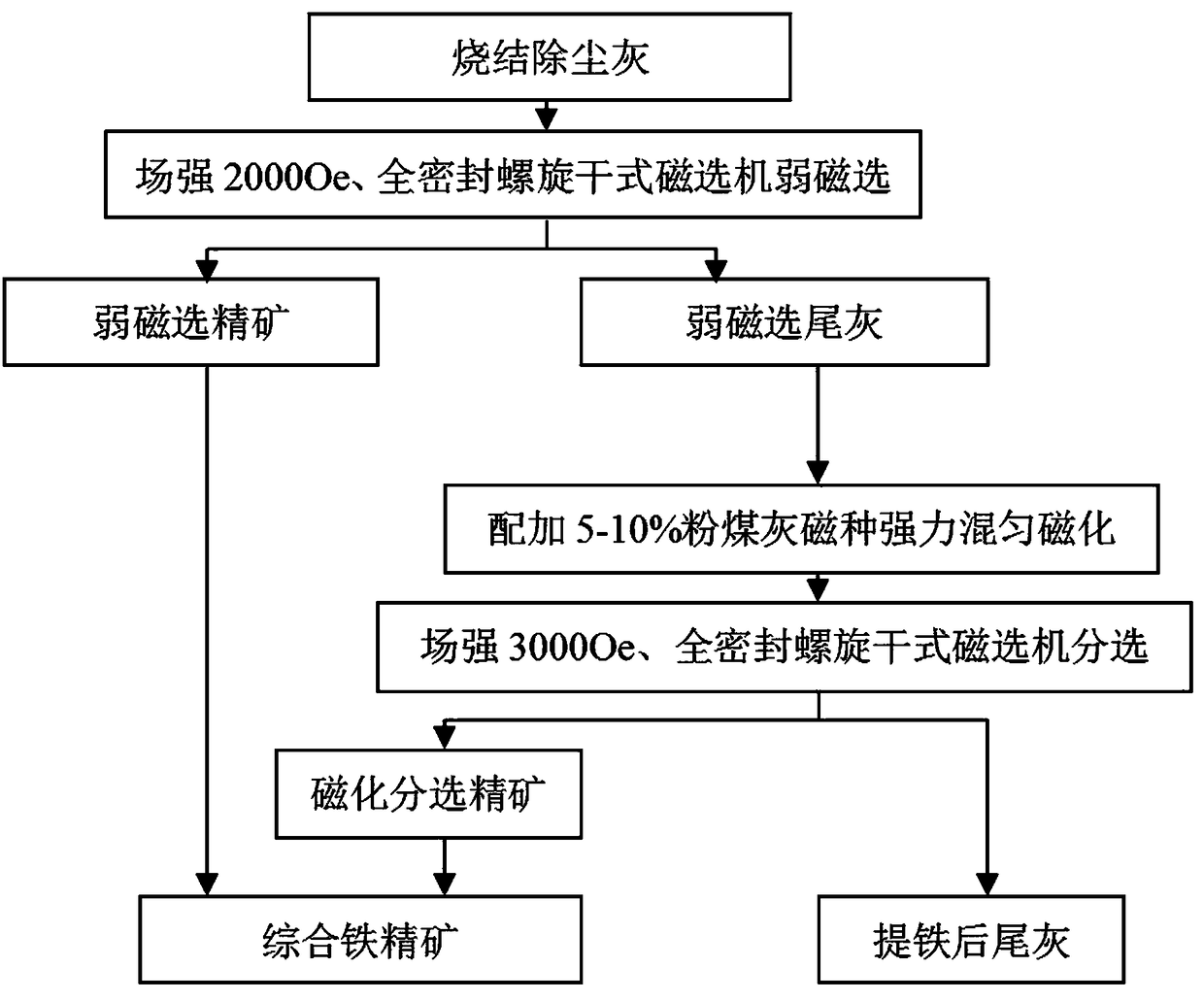

[0017] A sintering and dedusting ash magnetic seed magnetization dry separation process for iron extraction, specifically comprising the following steps:

[0018] Step A. adopt the spiral dry type magnetic separator of field strength 2000Oe, carry out weak magnetic iron extraction to dedusting ash, weak magnetic separation concentrate grade 56%, concentrate yield 20%, weak magnetic separation tail gray iron grade 26%, tailings The ash yield is 80%.

[0019] Step B. Add 5% fly ash magnetic seeds to the tail ash of weak magnetic separation, the grade is 56%, and the specific magnetic susceptibility coefficient is 90000 (1×10 - 9 m 3 / kg), heated to 70°C and vigorously mixed for magnetization, iron ions form magnetic aggregation with the magnet...

Embodiment 2

[0023] The sintering dust removal ash that this implementation of the present invention adopts comes from Jiuquan Iron and Steel Sintering Plant, and the sintering dust removal ash of iron grade 35% is carried out following treatment:

[0024] A sintering and dedusting ash magnetic seed magnetization dry separation process for iron extraction, specifically comprising the following steps:

[0025] Step A. adopt the spiral dry magnetic separator of field intensity 2000Oe, carry out weak magnetic iron extraction to dedusting ash, weak magnetic separation concentrate grade 57%, concentrate yield 22%, weak magnetic separation tail gray iron grade 28.8%, tailings The ash yield is 78%.

[0026] Step B. Add 10% fly ash magnetic seeds to the tail ash of weak magnetic separation, the grade is 56%, and the specific magnetic susceptibility coefficient is 95000 (1×10 -9 m 3 / kg), heated to 70°C and vigorously mixed for magnetization, iron ions form magnetic aggregation with the magnetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific susceptibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com